Alkaline water electrolysis Ni-based three-dimensional network gradient alloy hydrogen evolution cathode

A hydrogen evolution cathode and three-dimensional mesh technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problem of hydrogen evolution activity decline, achieve the effect of increasing the roughness, increasing the catalyst coating area, and improving the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

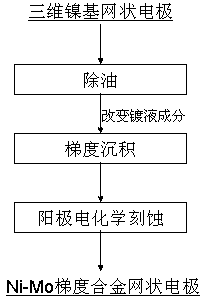

Method used

Image

Examples

Embodiment 1

[0032] After the Ni mesh electrode (2cm*2cm*0.2cm) is degreased by alkali, the Ni-Mo alloy coating is deposited gradiently. The bath composition is NiSO 4 ?6H 2 O 200g / L, NiCl 2 ?6H 2 O 40g / L, Na 3 C 6 h 5 o 7 ?2H 2 O 90g / L, Na 2 MoO 4 10g / L. The volume of the plating solution is 200ml. After 2 minutes of deposition, gradually add 100g / l Na to the plating solution 2 MoO 4 solution, the dropping rate is 2.5ml / min. After 20min, the contents of Ni and Mo in different alloy layers after deposition are as follows: image 3 As shown, the deposition current density is 20mA / cm 2 , the counter electrode is a Ni sheet electrode, and the electrodeposition temperature is 65°C. After deposition, place in 2mol / L-NH 3 -1mol / L NH 4 Constant current 10mA / cm in Cl etching bath 2 The anode was etched for 5 minutes, and the etching temperature was 25°C. The surface of the catalyst after etching was as follows: Figure 4 As shown, the surface of the electrode is rough, the sp...

Embodiment 2

[0035] After the Ni mesh electrode (2cm*2cm*0.2cm) is degreased by alkali, the Ni-Mo alloy coating is deposited gradiently. The bath composition is NiSO 4 150g / L, NiCl 2 80g / L, Na 3 C 6 h 5 o 7 120g / L. The volume of the plating solution is 200ml. After deposition for 1min, gradually add 10g / l Na to the plating solution 2 MoO 4 Solution, the dropping rate is 4ml / min. The dropping time is 15min, and the deposition current density is 15mA / cm 2 , the counter electrode is a Ni sheet electrode, and the electrodeposition temperature is 70°C. After deposition, place in 4mol / L NH 3 -2mol / L NH 4 The anode was etched in a Cl electrochemical etching tank for 3 min at a temperature of 75 °C, and then washed and dried to form a Ni-Mo mesh alloy active cathode.

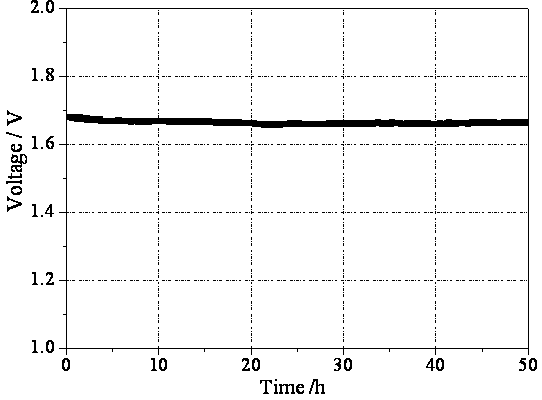

[0036] Shanghai Chenhua CHI660C electrochemical test station was used to test the polarization overpotential of the electrode, the scanning speed was 2mV / s, the electrolyte solution was 6mol / L NaOH, 70°C, and t...

Embodiment 3

[0038] After the Ni mesh electrode (2cm*2cm*0.2cm) is degreased by alkali, the Ni-Mo alloy coating is deposited gradiently. The bath composition is NiSO 4 150g / L, NiCl 2 80g / L, Na 3 C 6 h 5 o 7 120g / L, lead acetate (CH 3 COO) 2 Pb 0.03g / L. The volume of the plating solution is 200ml. After 2 minutes of deposition, gradually add 100g / L Na to the plating solution 2 MoO 4 Solution, the dropping rate is 3ml / min. The dropping time is 15min, and the deposition current density is 25mA / cm 2 , the counter electrode is a Ni sheet electrode, and the electrodeposition temperature is 70°C. After deposition, place in 2mol / L NH 3 -1mol / L NH 4 Constant current 20mA / cm in Cl etching bath 2 The anode was etched for 1 min, the etching temperature was 25°C, and then washed and dried to form a Ni-Mo mesh alloy active cathode.

[0039] Shanghai Chenhua CHI660C electrochemical test station was used to test the polarization overpotential of the electrode, the scanning speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com