Preparation method of C5/C9 hydrocarbon resin

A technology for hydrogenating petroleum resins and petroleum resins, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc. The effect of improving compatibility and reducing energy consumption in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

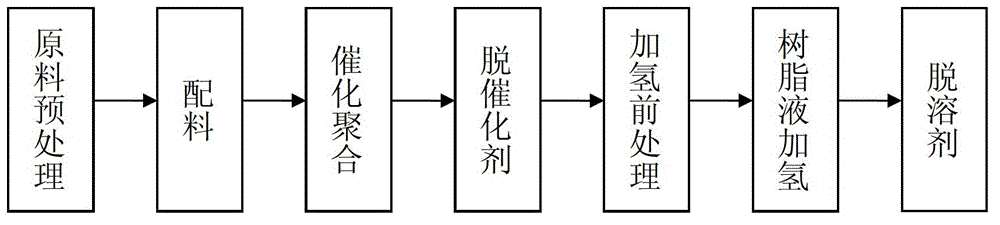

[0081] The following table 8 is the embodiment of preparing C5 / C9 petroleum resin, the raw material is Pd / Al 2 o 3 The processes of catalyst selective hydrogenation, Friedel-Crafts catalyst pretreatment and subsequent catalyst removal, raw material rectification to remove oligomers, solvent dilution, and resin polymerization liquid catalyst removal are as follows:

[0082] (1) Prepare C5 / C9 petroleum resin polymerization raw material D from three raw materials A, B, and C;

[0083] (2) After dehydrating the above-mentioned polymerization raw material D through a 4A molecular sieve packed tower, use Pd / Al 2 o 3 The catalyst is selectively hydrogenated to remove alkynes, then add Friedel-Crafts catalyst and pre-polymerize at room temperature for 0.5-1.5 hours, then remove the catalyst with a mixture of calcium hydroxide and methanol, and obtain polymerization raw materials with a boiling point of 25-180°C after distillation Fraction E;

[0084] (3) Thermally prepolymerizing ...

Embodiment 7~10

[0090] Table 9 is an example of the hydrogenation process in the method of the present invention. The C5 / C9 petroleum resin liquid used in Examples 7 to 10 is prepared by the polymerization process in Example 2, and is removed by vacuum distillation in the post-hydrogenation treatment. The solvent and oligomer process technology is:

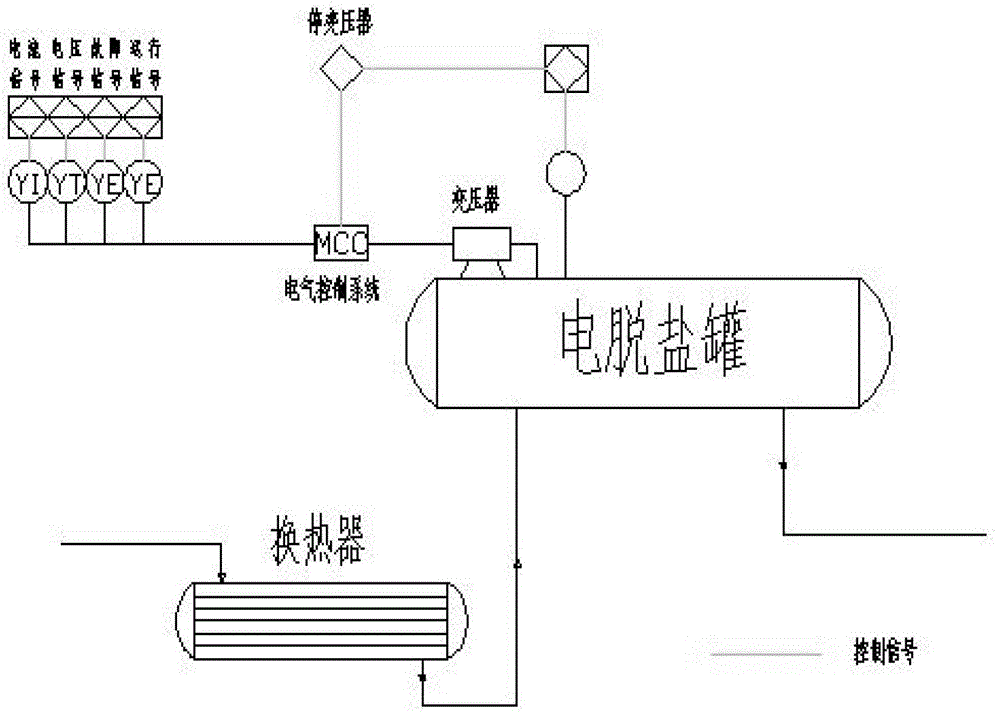

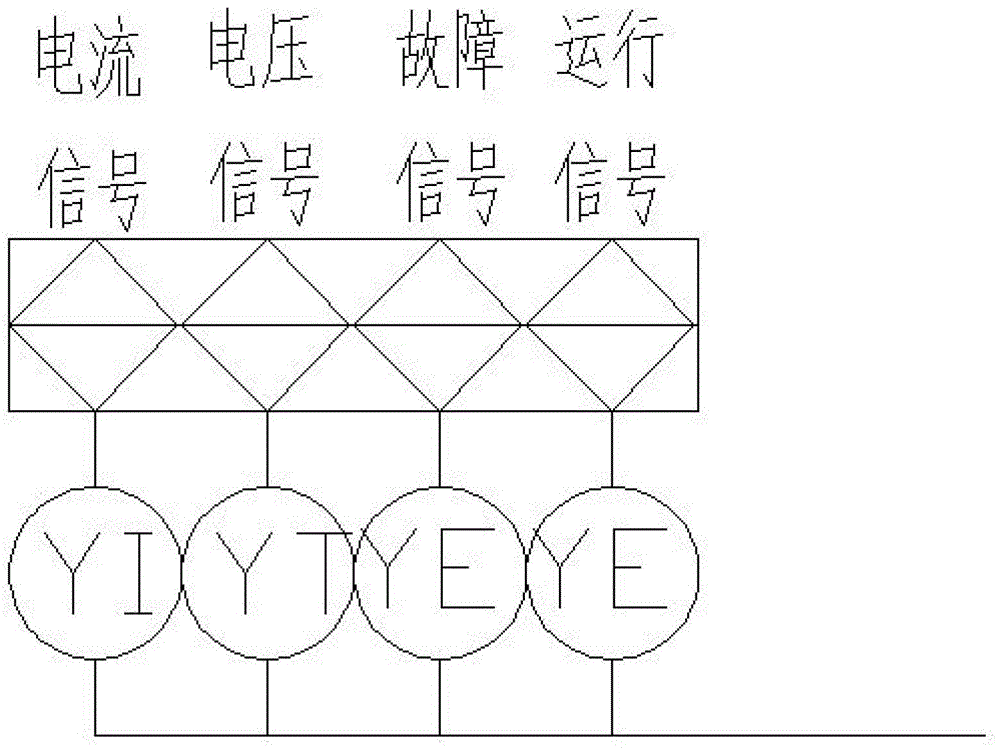

[0091] (1) The above resin solution is dehydrated by electro-desalting, and then passed through active Al 2 o 3 solid bed;

[0092](2) The C5 / C9 petroleum resin liquid after the above pretreatment is dissolved in a diluting solvent, and hydrogenation reaction is carried out in the presence of a modified Pd catalyst to obtain a hydrogenated diluted resin liquid;

[0093] (3) Remove the solvent and oligomers from the above-mentioned hydrogenated diluted resin liquid through a vacuum rectification tower with an operating pressure of -0.075 ~ -0.090 MPa and a temperature of 220 ° C to obtain C5 / C9 hydrogenated petroleum resin .

[0094] The hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com