Extraction method and device for strontium sulfide

A technology of strontium sulfide and extractor, which is applied in the direction of magnesium/calcium/strontium/barium sulfide/polysulfide, etc., can solve the problems that restrict the survival and development of enterprises, the easy oxidation of strontium sulfide, and the low degree of automation. Save energy, reduce labor intensity of workers, and achieve high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

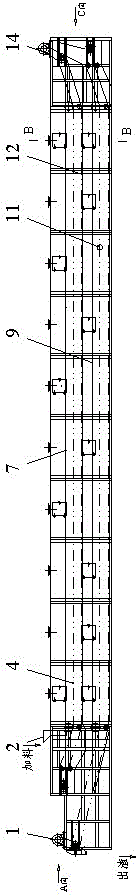

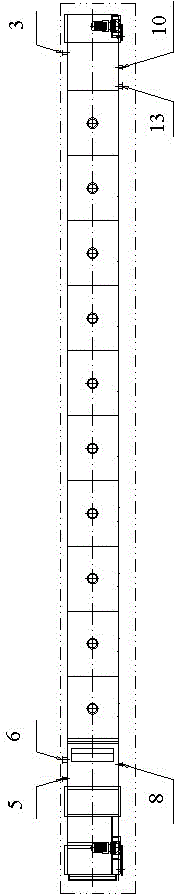

[0025] Example: The continuous extractor of strontium sulfide of the present invention, as Figure 1~5 As shown, it includes a closed hydrolysis box, the hydrolysis box is a two-layer structure, an upper water tank 7 and a lower water tank 9, the inner water tanks of each layer are separated, and each layer adopts independent transmission and independent water circulation. The upper water tank 7 is provided with a material inlet 2, a layer of water inlet 3, a layer of moving mesh belt 4, a layer of water outlet 5, a layer of slag discharge port 6, and a layer of transmission device 14. The material inlet 2 is arranged on the The upper part of one end of the hydrolysis box is directly facing the one-layer transmission mesh belt 4; the material inlet 2 is provided with a distributor; the one-layer water inlet 3 is arranged at the other end of the hydrolysis box. The lower water tank 9 is provided with a second-layer water inlet 8, a second-layer water outlet 10, a second-layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com