Full automatic closing type stripping imaging machine

A closed and fully automatic technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of wasting resources, consumption, and increasing the work intensity of operators, so as to increase the utilization rate , the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

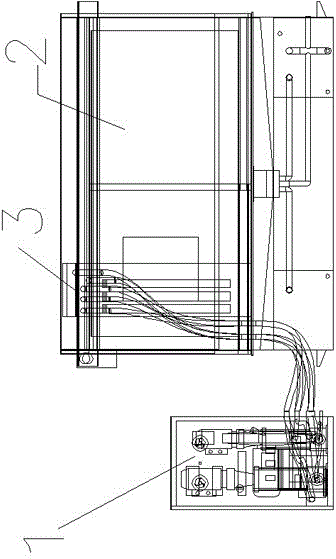

[0031] The present invention will be further explained with reference to the drawings.

[0032] Such as figure 1 As shown in —9, a fully automatic closed film release developing machine is characterized in that it includes an auxiliary machine 1, a main machine 2, a core working part 3; the auxiliary machine 1 is provided with a high-pressure stripping pump 4, The imaging high-pressure pump 5, the high-pressure clean water pump 6, the high-pressure fan 7, the electrical cabinet 8, and the corresponding pipelines; the main unit 2 is provided with a release agent tank 17, a clean water tank 18, a main unit housing 20, and a left door of the main unit 21. Host right door 22, operation panel 23, solenoid valve I 27, solenoid valve II 28, solenoid valve III 29; the core working part 3 is provided with a mounting beam 24, a walking motor 19, a transmission chain 25, and a nozzle mounting plate 23, Grid frame 26;

[0033] It is also characterized in that the auxiliary machine 1 is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com