Method for preparing environment-friendly starch/bentonite composite material

An environment-friendly and composite material technology, which is applied in the field of starch/bentonite composite material preparation, can solve the problems of insufficient resistance to mechanical agitation and stability, lack of water resistance and emulsification ability, paste liquid instability, etc., and achieve improved flocculation performance , low price and low desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 100 g of calcium-based bentonite with a particle size of 200 mesh, add 1.0 L of distilled water, stir for 2 hours, let stand for stratification, discard the bottom layer of particles larger than 2 μm, and take the upper layer of bentonite suspension for subsequent use;

[0026] (2) Sodiumization: add 2.5L of 0.50mol / L NaCl solution to the bentonite aqueous solution, stir for 24 hours, and discard the supernatant after standing for stratification; then add 2.5L of 0.50mol / L NaCl solution for secondary sodiumization , stirred for 12 hours, allowed to stand for stratification, and discarded the supernatant; centrifuged the bentonite suspension at a speed of 8000rpm for 20min, poured off the supernatant, added distilled water, and repeated washing until there was no Cl- in the supernatant (using AgNO 3 Solution test (Cl-); dry the washed sample at 80°C, grind it into powder, and pass through a 100-mesh sieve to obtain purified bentonite after sodium;

[0027] (3) ...

Embodiment 2~6

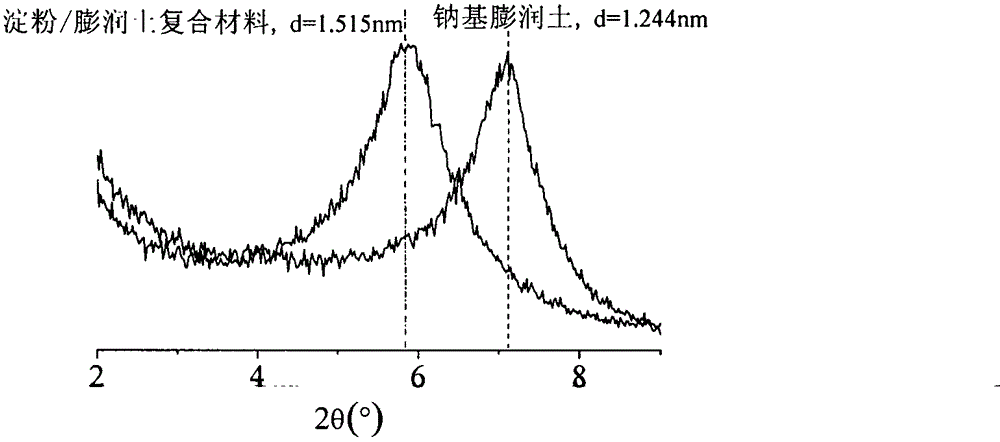

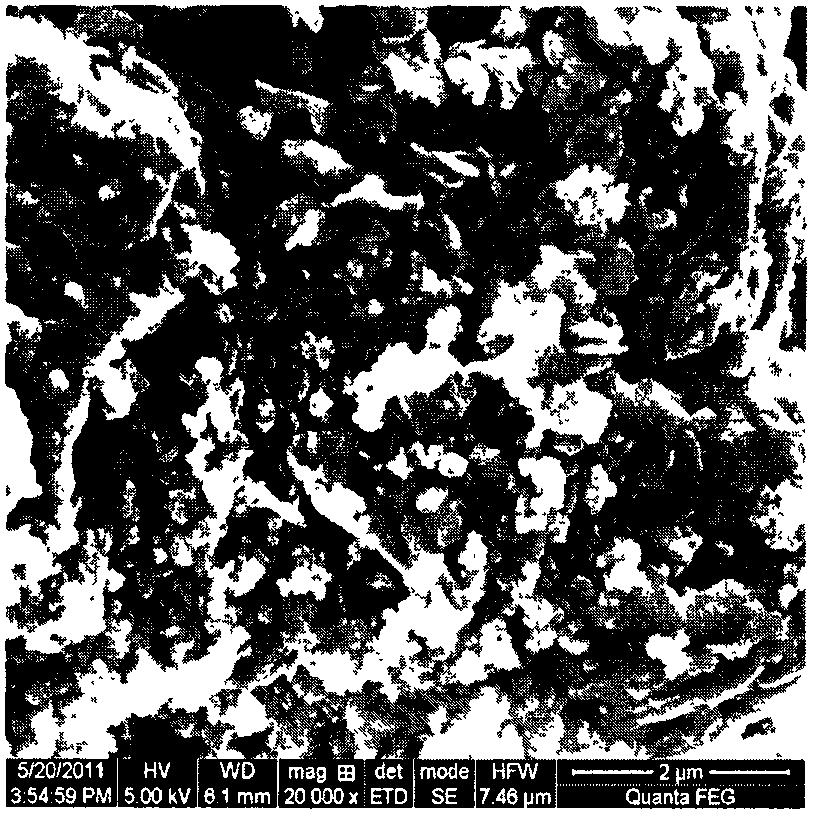

[0035] Implementation method is the same as Example 1, change the granularity of calcium-based bentonite in step (1), NaCl solution concentration in step (2), cationic degree, concentration, solution pH of cationic starch in step (3), in step (4) The mass ratio of sodium bentonite to starch solution, water bath temperature, stirring time, starch content, Zeta potential and interlayer distance d of the obtained starch / bentonite composite 001 And the removal rates of methylene blue, Congo red, p-nitrophenol and Cr(VI) in water are shown in the table below.

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com