Method for improving reconstituted tobacco paper-base quality through adding calcium carbonate and reconstituted tobacco paper-base

A technology for reconstituted tobacco leaves and calcium carbonate, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of lack of stable and feasible technical solutions with clear effects, lack of analysis and research, and unclear impact mechanism, so as to improve surface properties and Effect of internal structure, improved running performance and effectiveness, improved air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of reconstituted tobacco leaf paper base by conventional method

[0023] (1) Dipping and extracting tobacco stems and tobacco powder respectively;

[0024] Dipping and extracting tobacco stems and tobacco powder respectively. The conditions for the steeping and extraction of the tobacco stems are that the ratio of solid to liquid is 1:7 (mass ratio), the extraction temperature is 60°C, and the extraction time is 100 minutes (min); the conditions for the steeping and extraction of the tobacco powder are that the ratio of solid to liquid is 1: 10. The extraction temperature is 70°C, and the extraction time is 60 min; the extracts of tobacco stems and tobacco powder obtained after the impregnation treatment are mixed according to a volume ratio of 1:1, and then conventionally evaporated and concentrated to obtain a coating liquid; after the impregnation treatment, the tobacco stems, Tobacco solids are used for refining.

[0025] (2) Refining: the ...

Embodiment 2

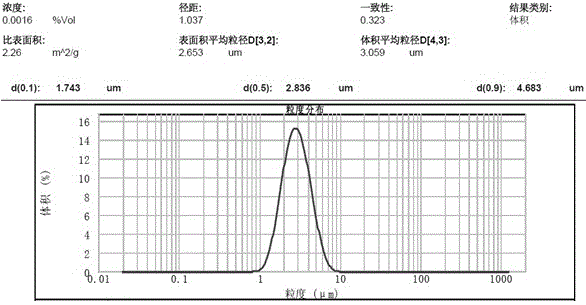

[0032] The particle size distribution of embodiment 2 calcium carbonate particles

[0033] Take calcium carbonate powder, add water and be mixed with the calcium carbonate solution that the mass percentage concentration is 0.0016%, carry out particle size analysis, the analysis result of calcium carbonate particle size distribution sees figure 1 .

[0034] attached by figure 1 It can be seen that calcium carbonate for papermaking itself is not a spherical particle, and its diameter does not represent an absolute diameter in the usual sense. Integral curves, where the diameter can only be the statistical mean of all changing values. The particle size value is not unique, it is related to the instrument and statistical method used for measurement. No matter what kind of particle size analyzer (laser or sedimentation) is used, it is impossible to measure the distance between two points connecting the particle surface through the center of gravity, so the measured particle si...

Embodiment 3

[0043] Example 3 Effect of adding different amounts of guar gum on the quality of reconstituted tobacco paper base

[0044] Prepare the reconstituted tobacco leaf paper base according to the steps in Example 1, wherein in step (4), add the tobacco mixed slurry to tap water to prepare a tobacco slurry suspension with a solid content of 0.5 wt.%, disperse evenly, and add to it under low-speed stirring Calcium carbonate aqueous solution (concentration is 20g / L, stir the solution to make it evenly mixed), so that the final mass percentage of the added calcium carbonate in the mixed slurry is 50%. Stir for 30 seconds, add the guar gum suspension, continue to stir for 1 minute, and quickly make a tablet. The other steps are the same as in Example 1. The amount of guar gum added is increased from 0% to 1.5% (based on the final mass percentage of guar gum in the mixed slurry), and a variety of reconstituted tobacco leaf paper bases are prepared, and thin paper is obtained after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear index | aaaaa | aaaaa |

| Bulk | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com