A kind of polylactic acid fiber tobacco tow and preparation method thereof

A polylactic acid fiber, polylactic acid technology, applied in the application, tobacco, smoke oil filter and other directions, can solve the problems of cigarette sensory quality, difficult to eliminate pollution, non-biodegradable and other problems, and achieve good recyclability and biodegradation. improve the effect of reducing coke and damage, and reducing the effect of interlayer peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

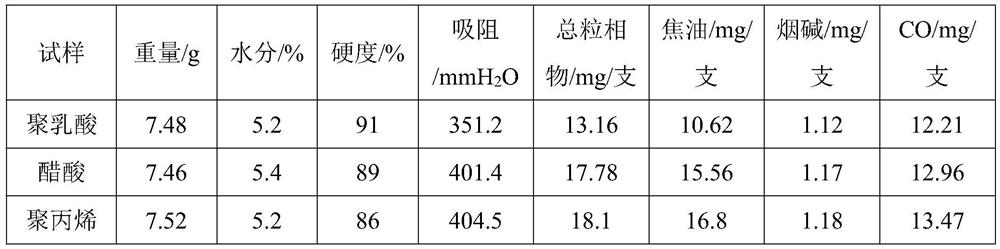

Image

Examples

Embodiment 1

[0047] A polylactic acid fiber tow for tobacco, the tow for tobacco is composed of a single fiber with a core-wrapped structure, and the core-wrapped structure has a three-layer structure of outer layer-inner layer-core layer in sequence, wherein , the outer layer is polylactic acid resin added with pore-forming agent and tourmaline superfine powder, the addition of pore-forming agent in the outer layer is 13wt%, the addition of tourmaline superfine powder is 7wt%, and the inner layer is Polypropylene resin added with pore-forming agent, metal oxide ultrafine powder, compatibilizer and crystallization nucleating agent, the metal oxide is MgO, the pore-forming agent is NaCl, the pore-forming agent, metal oxide in the inner layer The addition amount of superfine powder, polyethylene glycol and crystallization nucleating agent is respectively 8wt%, 10wt%, 2wt%, 2wt%. The particle size of the micropowder and crystal nucleating agent is 0.1-5 μm, the core layer is polylactic acid, ...

Embodiment 2

[0049] A polylactic acid fiber tow for tobacco, the tow for tobacco is composed of a single fiber with a core-wrapped structure, and the core-wrapped structure has a three-layer structure of outer layer-inner layer-core layer in sequence, wherein , the outer layer is polylactic acid resin added with pore-forming agent and tourmaline superfine powder, the addition of pore-forming agent in the outer layer is 10wt%, the addition of tourmaline superfine powder is 10wt%, and the inner layer is Polypropylene resin added with pore forming agent, metal oxide ultrafine powder, compatibilizer and crystallization nucleating agent, the metal oxide is TiO 2 , the pore-forming agent is K 2 SO 4 , the addition of pore forming agent, metal oxide superfine powder, polyethylene glycol and crystallization nucleating agent in the inner layer is respectively 12wt%, 4wt%, 5wt%, 6wt%, and described crystallization nucleating agent is talcum powder, so The particle size of the pore-forming agent, m...

Embodiment 3

[0051] A kind of preparation method of polylactic acid fiber tobacco tow described in embodiment 1, comprises the following steps:

[0052] S1. Vacuum-dry each spinning raw material at a drying temperature of 80-120°C and a drying time of 4-10 hours, so that the water content is not higher than 200ppm;

[0053] S2. Prepare the spinning raw materials according to the ratio, melt and blend them in the internal mixer or twin-screw, prepare the outer layer, inner layer and core layer spinning molten raw materials respectively, after filtering, quantitatively input the composite spinning assembly by the metering pump, The spinning melt flows separately in the isolated cavities of the composite spinning assembly, and is extruded from the same circular spinneret hole. The number of spinneret holes is 8000-12000, and it is air-cooled and solidified at 15-25°C;

[0054] S3. Draw in a water bath at a temperature of 50-70°C, the draw ratio is 2-3, the draw speed is less than 300m / min, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com