Wire grid type polarizer and method for manufacturing same

A manufacturing method and polarizer technology, which can be applied in polarizing elements, nonlinear optics, optics, etc., and can solve problems such as image contrast reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

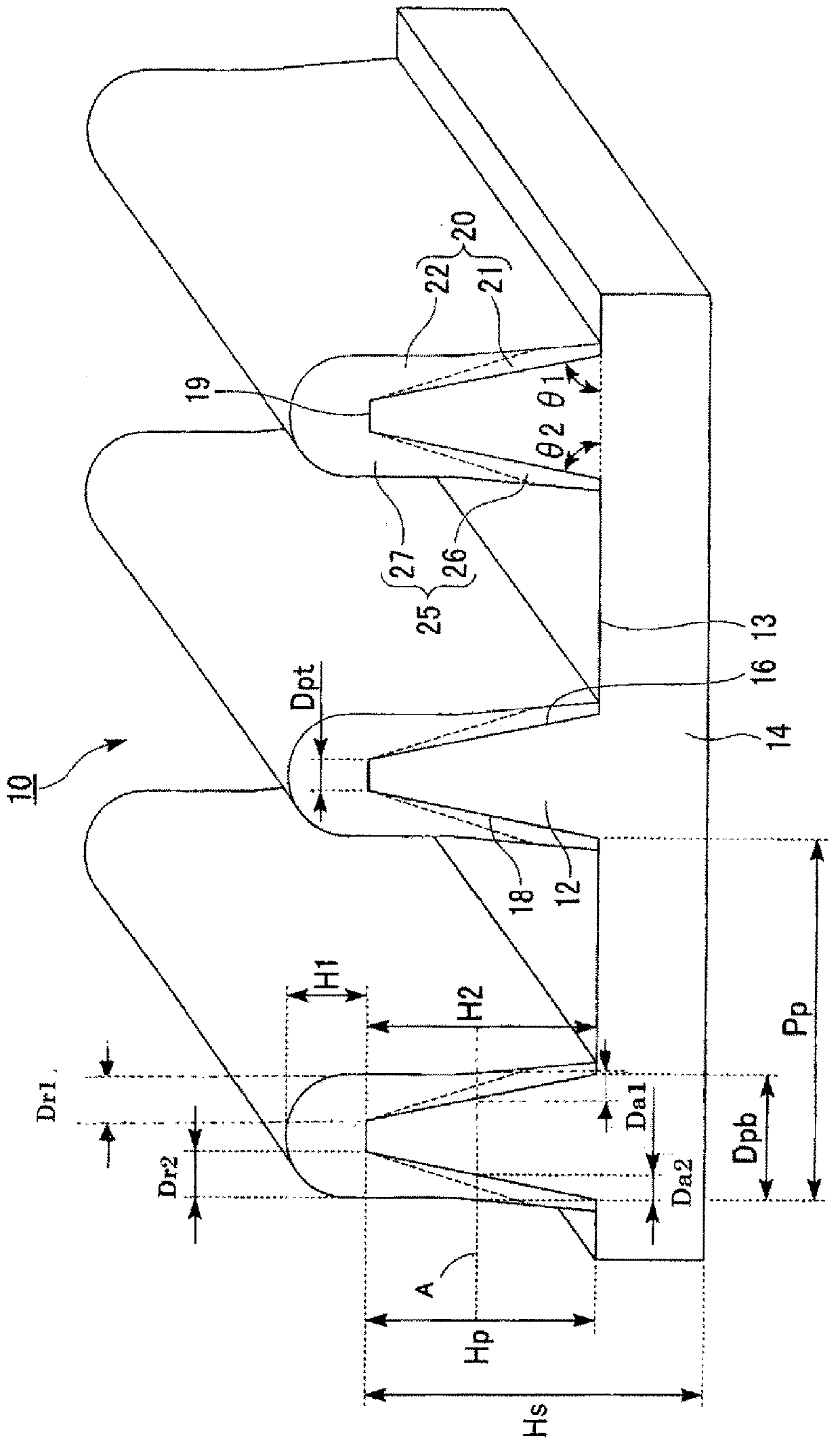

[0101] figure 1 It is a perspective view showing the first embodiment of the wire grid polarizing plate of the present invention. The wire-grid polarizer 10 has a light-transmitting substrate 14 and a first metal layer 20. On the light-transmitting substrate 14, a plurality of ridges 12 with a trapezoidal cross-sectional shape are formed, and the ridges 12 are formed on the ridges. The flat portions 13 of the grooves between the bars 12 are formed on the surface of the light-transmitting substrate 14 parallel to each other and separated by a predetermined pitch Pp. Or metal compound, the first metal layer 20 starts from the position of half the height of the convex strip 12 (at figure 1 Indicated by the dotted line A) to the bottom, the maximum value of the covering thickness is less than the maximum value of the covering thickness from the position of half the height of the raised bar 12 to the top 19 . The first metal layer 20 extends in the longitudinal direction of the r...

no. 2 Embodiment approach

[0123] figure 2 It is a perspective view showing the second embodiment of the wire grid polarizing plate of the present invention. The wire grid polarizing plate 10 has a light-transmitting substrate 14, a first metal layer 20, and a second metal layer 25. On the light-transmitting substrate 14, a plurality of convex lines 12 having a trapezoidal cross-sectional shape are formed. The flat portions 13 of the grooves formed between the protrusions 12 are formed on the surface of the light-transmitting substrate 14 parallel to each other and separated by a predetermined pitch Pp, and the first metal layer 20 covers the first portions of the protrusions 12 . 1 side surface 16 and is made of metal or metal compound, the first metal layer 20 is from the position of half the height of the convex strip 12 (at figure 2 Indicated by dotted line A) the maximum value of the covering thickness to the bottom is less than the maximum value of the covering thickness from the half height po...

no. 3 Embodiment approach

[0130] image 3 It is a perspective view showing a third embodiment of the wire grid polarizing plate of the present invention. The wire grid polarizing plate 10 has a light-transmitting substrate 14, a first metal layer 20, and a second metal layer 25. On the surface of the light-transmitting substrate 14, a plurality of convex lines 12 with a trapezoidal cross-sectional shape are formed. The strips 12 are formed on the surface of the translucent substrate 14 so that the flat portions 13 of the grooves 13 formed between the convex strips 12 are parallel to each other and separated by a predetermined pitch Pp, and the first metal layer 20 covers the convex strips 12. The first side 16 of the ridge 12 is made of metal or a metal compound. image 3 Indicated by dotted line A) the maximum value of the covering thickness to the bottom is less than the maximum value of the covering thickness from the half height position of the raised bar 12 to the top 19, the second metal layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com