Method for producing frozen bread dough needing no thawing or fermentation step

A technique for freezing dough and a manufacturing method, which is applied in the direction of dough processing, dough cooling, and pre-baked dough processing, etc., which can solve problems such as poor appearance, low storage efficiency, and disappearance of aroma and flavor, and achieve improved taste, flavor, and appearance. , reduce the effect of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

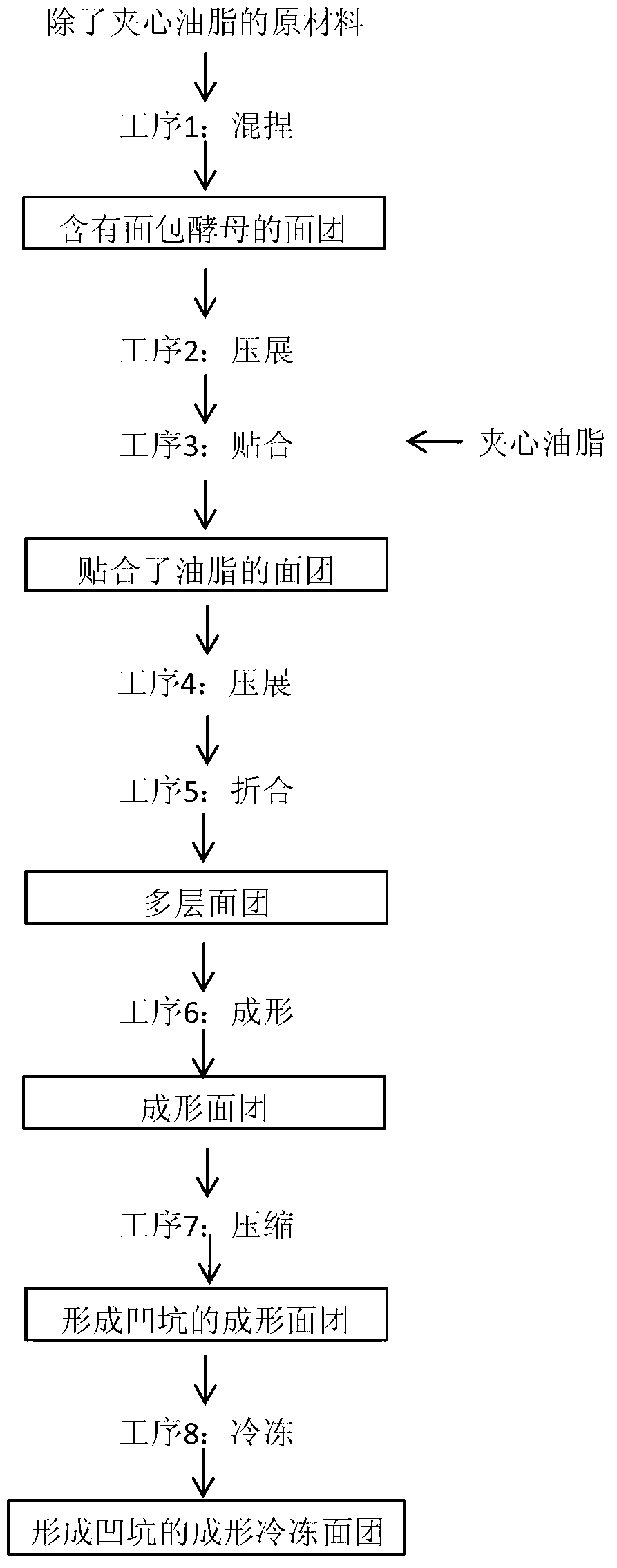

[0041] Based on the raw material mix shown in Table 1 with figure 1 In the manufacturing process shown, the formed frozen dough was made, and the baked bread was evaluated. Among the raw materials shown in Table 1, use a mixer (Kanto Mixer Industry: Vertical Mixer SS Type 111) to rotate the raw materials except for the sandwich oil at low speed for 5 minutes, medium speed for 6 minutes, and high speed for 0.5 minutes Kneading is carried out (dough temperature at the end of mixing is 15 °C). The obtained dough containing baker's yeast is pressed into a sheet with a thickness of 10mm by a reverse noodle machine (Kamada Machinery Manufacturing Co., Ltd.: リバスシターKR430Y), and the sandwich grease is spread on it, and the opposite side The greased side of the dough is brought together with the ends of the sheet dough to obtain a greased dough.

[0042] [Table 1]

[0043] Raw material name

Mixing amount (flour based %)

Wheat Flour (Strength ...

Embodiment 2

[0053] Based on the raw material mix shown in Table 3 with figure 1 In the manufacturing process shown, the frozen dough with dimples was produced, and the baked bread was evaluated. Among the raw materials shown in Table 3, the raw materials except shortening and sandwich fat were passed through a mixer (Kanto Mixer Industry: vertical mixer SS type 111), at low speed for 3.5 minutes, medium speed for 6 minutes, After kneading at high speed for 1 minute, add shortening, and then knead at low speed for 4 minutes, medium speed for 2 minutes, and high speed for 30 seconds (dough temperature at the end of mixing is 15°C). The obtained dough containing baker's yeast is pressed into a sheet with a thickness of 10 mm by a reverse noodle machine (Kamada Machinery Manufacturing Co., Ltd.: リバスシタ-KR430Y), and the sandwich grease is coated on it, and the opposite Fold the greased side of the side in half with the end of the sheet of dough to get a dough that is combined with the grease. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com