Thin film transistor and manufacturing method thereof

A technology of thin film transistors and manufacturing methods, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems affecting the production yield of thin film transistors, metal layer etching residues, and increase of cut-off current of thin film transistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

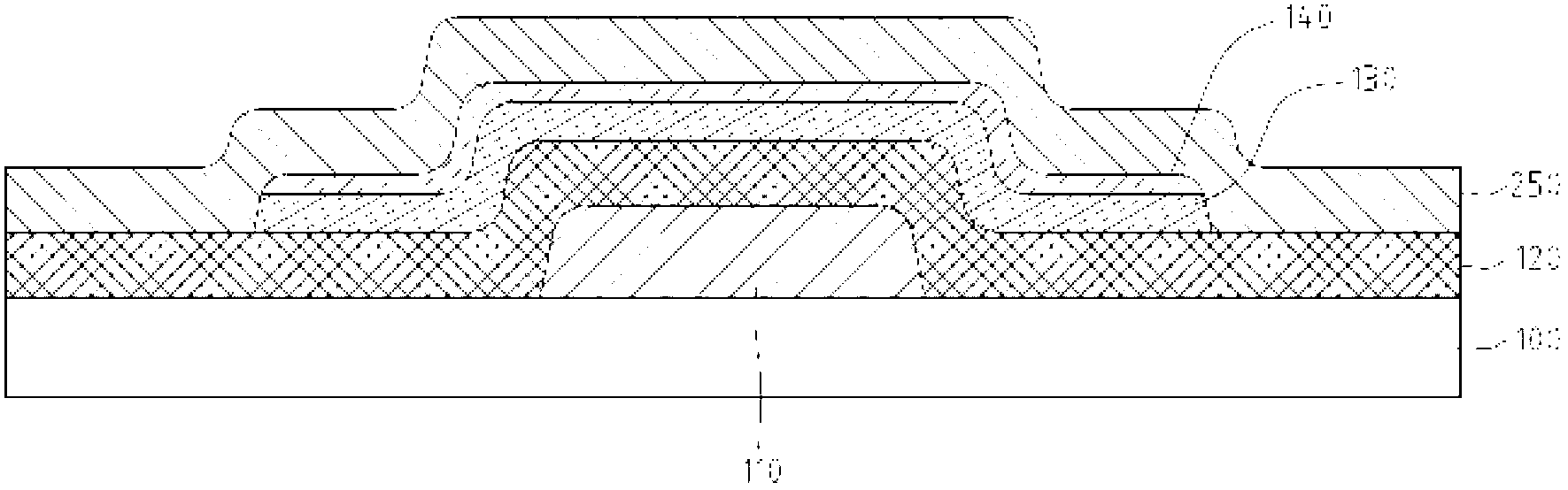

[0047] In order to make the present invention more comprehensible, preferred embodiments are introduced in detail below. The preferred embodiments of the present invention are provided with corresponding reference numerals in the drawings. In addition, terms such as "first" and "second" in the specification are used to distinguish different elements or processes, rather than to limit their order.

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

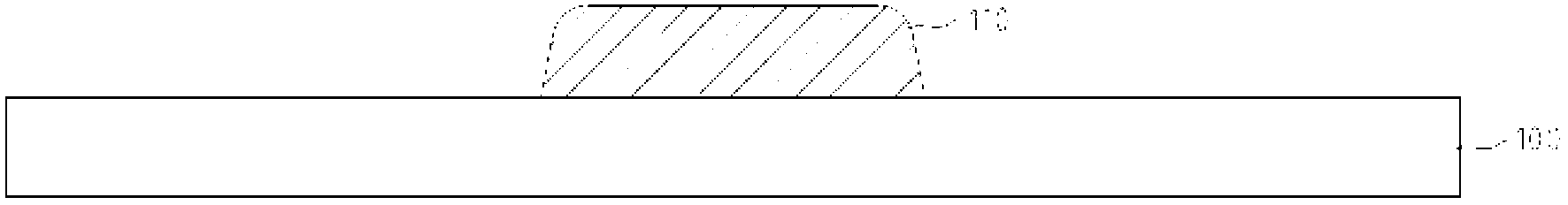

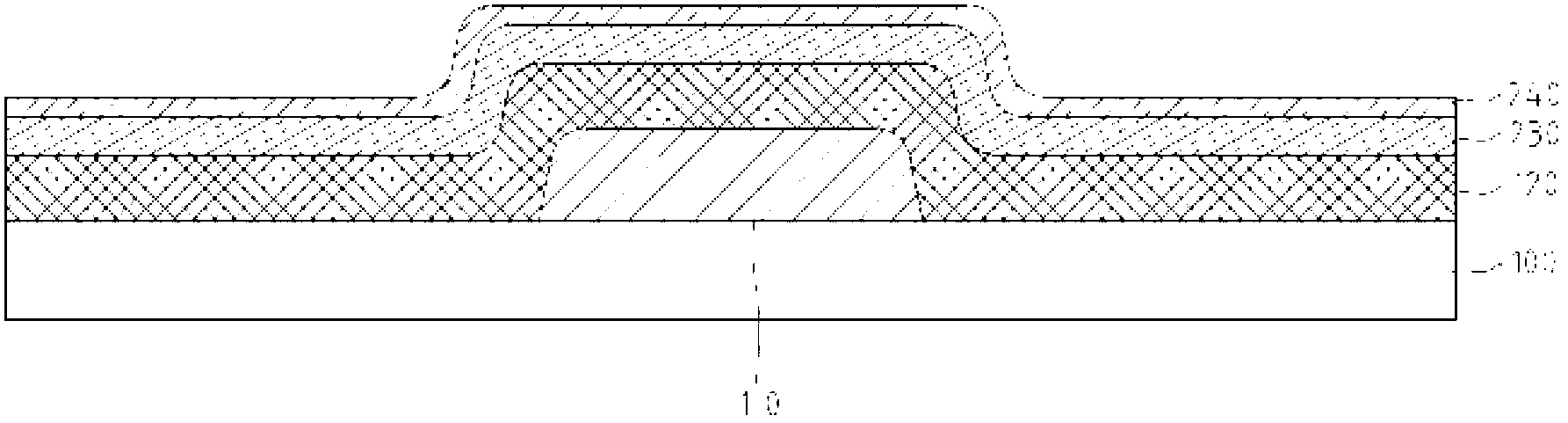

[0049] Please refer to figure 2 , figure 2 It is a flow chart of the manufacturing method of the thin film transistor substrate according to the first embodiment of the present invention. Firstly, step S10 is performed, forming and depositing a first metal layer on the substrate and etching to form a gate. Specifically, a substrate is firstly provided, and a first metal layer is deposited on the substrate, and then the first metal layer is patterned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com