Automatic friction sensitivity instrument

A sensitivity meter, automatic technology, applied in the field of friction sensitivity meter, can solve the problems of low efficiency, low degree of automation, danger, etc., to achieve the effect of convenient use, accurate angle hovering, and convenient lofting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

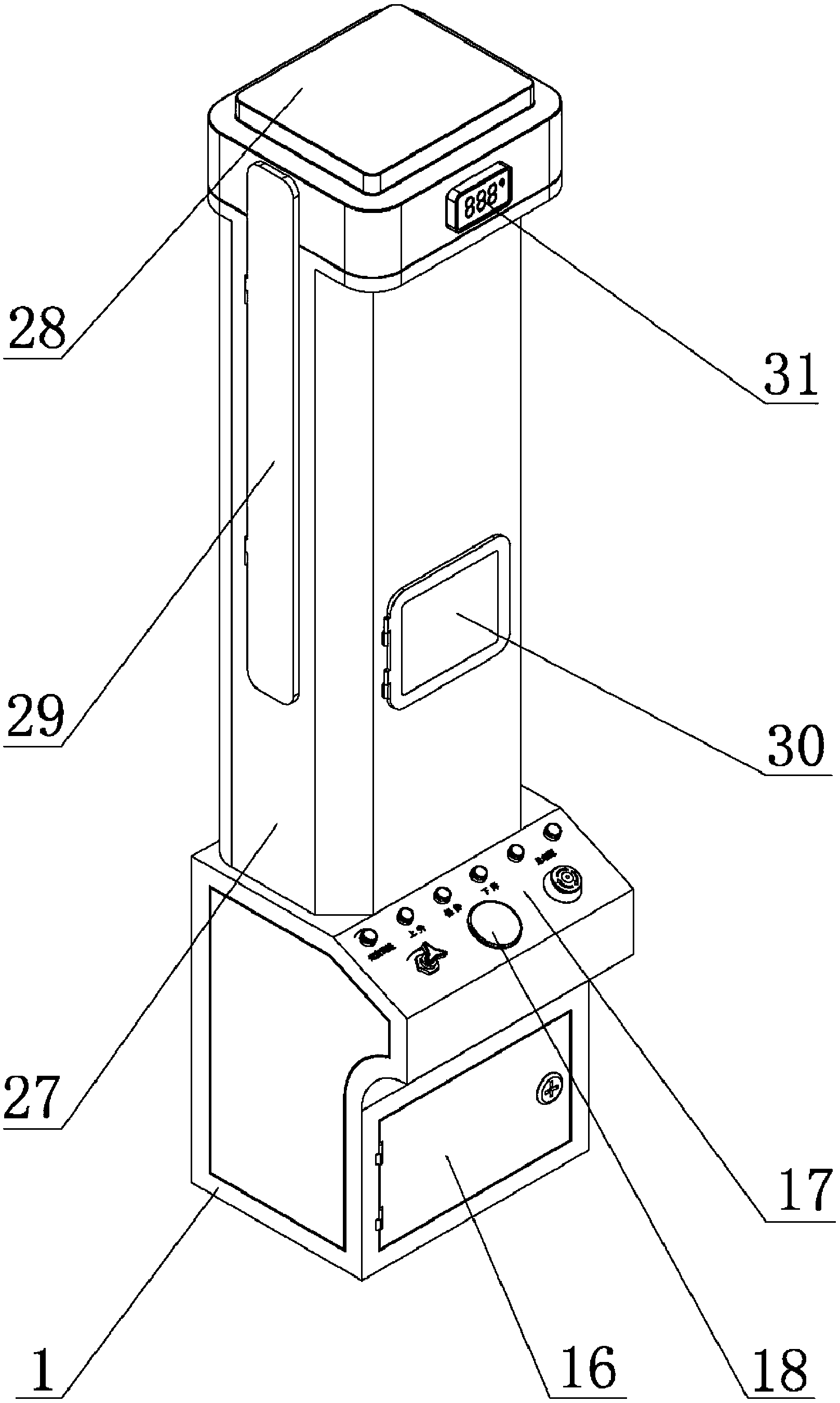

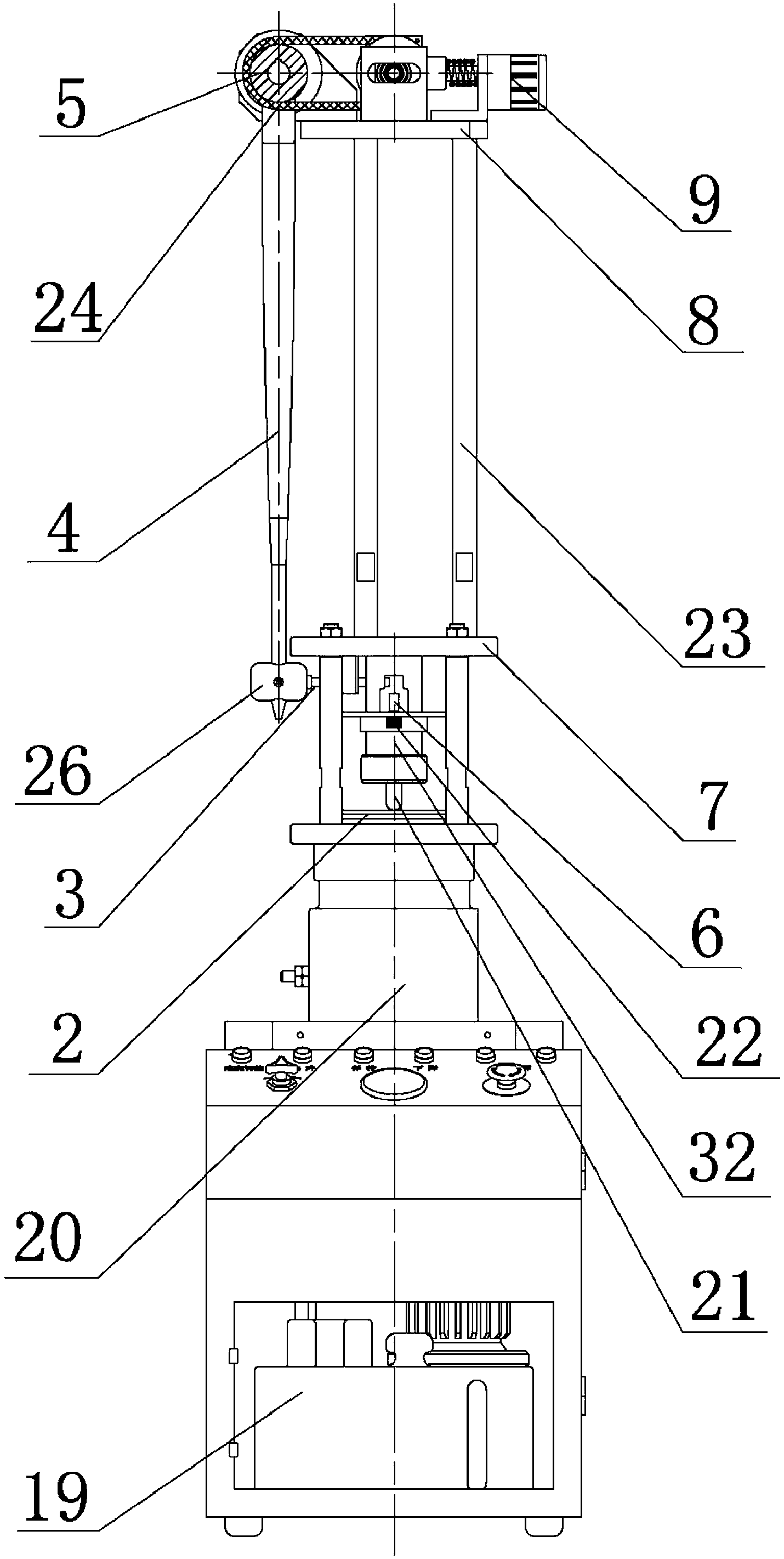

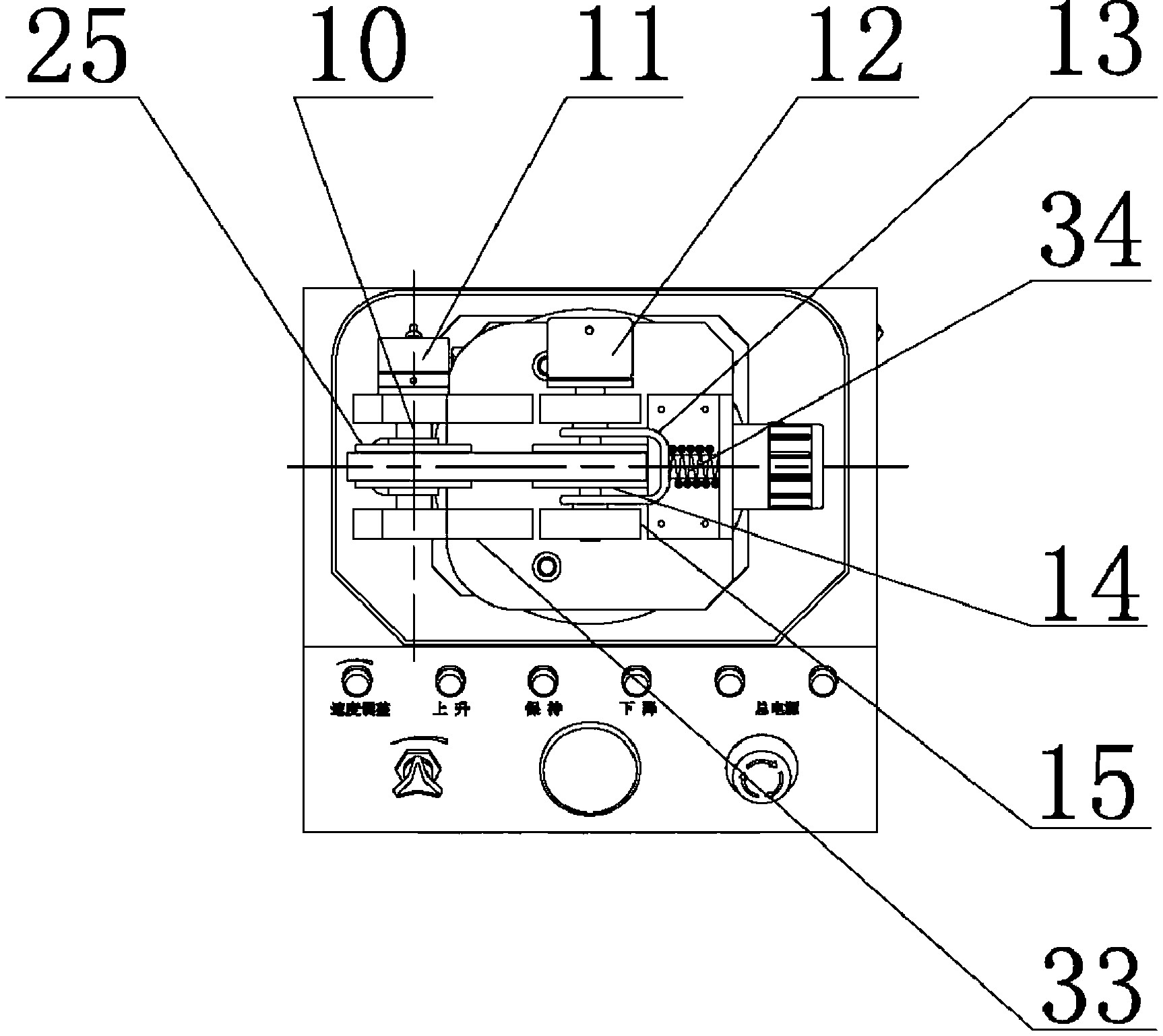

[0021] Please refer to the attached figure 1 To attach image 3 As shown, the present invention is an automatic friction sensitivity meter, which consists of a hydraulic tank 1, a hydraulic jack 2, a striker 3, a swing rod 4, a driven wheel 5, a sample friction device 6, a support seat 7, a transmission platform 8, an electric suction Magnetic 9, driven shaft 10, photoelectric encoder 11, driving motor 12, pull bar 13, driving wheel 14 and several parts such as motor guide seat 15 are formed.

[0022] Wherein, a box door 16 , a manual button panel 17 and a pressure gauge 18 are arranged on the outer surface of the hydraulic box 1 . An oil supply 19 is provided inside the hydraulic tank 1 , and the oil supply 19 is connected to a hydraulic cylinder 20 , and the hydraulic cylinder 20 abuts against the bottom of the hydraulic jack 2 .

[0023] The support seat 7 is located above the hydraulic top 2, and the sample friction device 6 is installed on the support seat 7. A push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com