A translational mode bituminous coal combustion furnace with temperature gradient function

A temperature gradient, combustion furnace technology, applied in furnace, electric furnace heating, furnace type and other directions, can solve the problems of short life and insertion of resistance wire, and achieve the effect of prolonging life, smooth movement and improving sample experiment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

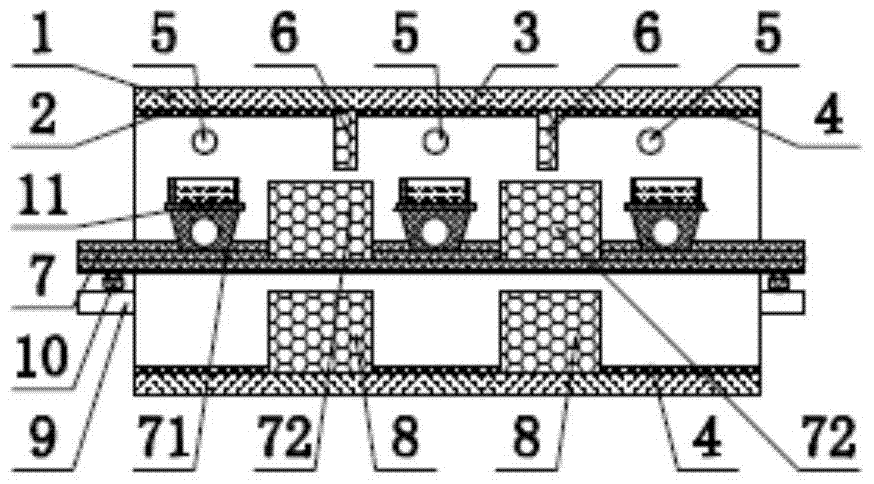

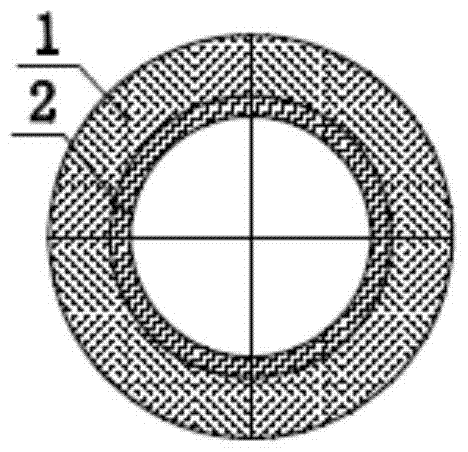

[0014] to combine figure 1 and figure 2 , a translation mode bituminous coal combustion furnace with temperature gradient function of the present invention, comprising a combustion furnace body 1, three resistance wires 2, 3 and 4 installed on the inner wall of the combustion furnace body 1, installed in the combustion furnace body 1 The third heat shielding plate 6 and the second heat shielding plate 8 on the inner wall, the moving ceramic plate 7 installed inside it parallel to the axis of the combustion furnace body 1, the first heat shielding plate installed on the moving ceramic plate 7 72. The roller frame 9 installed on the lower center of the left and right ends of the combustion furnace body 1.

[0015] to combine figure 1 and figure 2 , the combustion furnace body 1 is a thin-walled cylindrical body made of ceramic fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com