Method for arc bending excavation of lower bending section of vertical shaft

A vertical shaft and curved arc technology, applied in vertical shaft equipment, sinking, earthwork drilling and mining, etc., can solve problems such as missing, affecting total station measurement, total station can not get the visibility conditions, etc., to ensure accuracy and improve construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

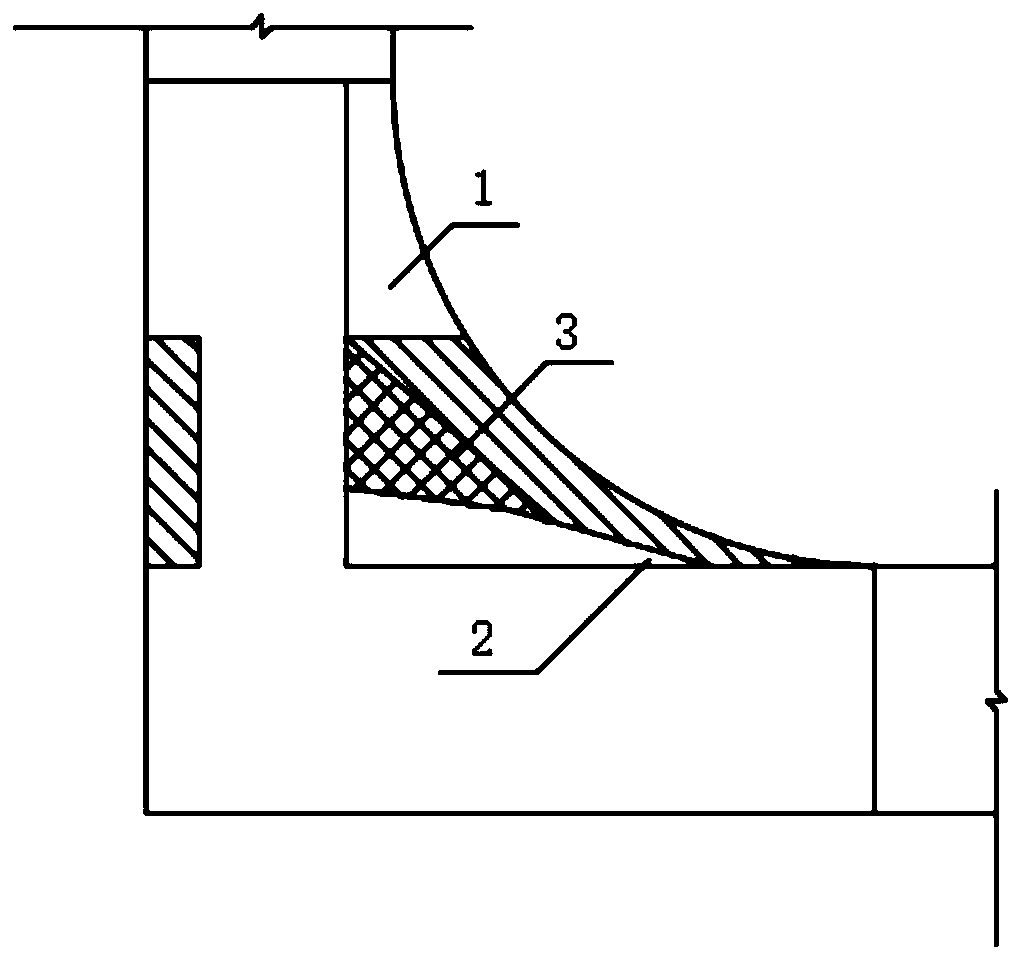

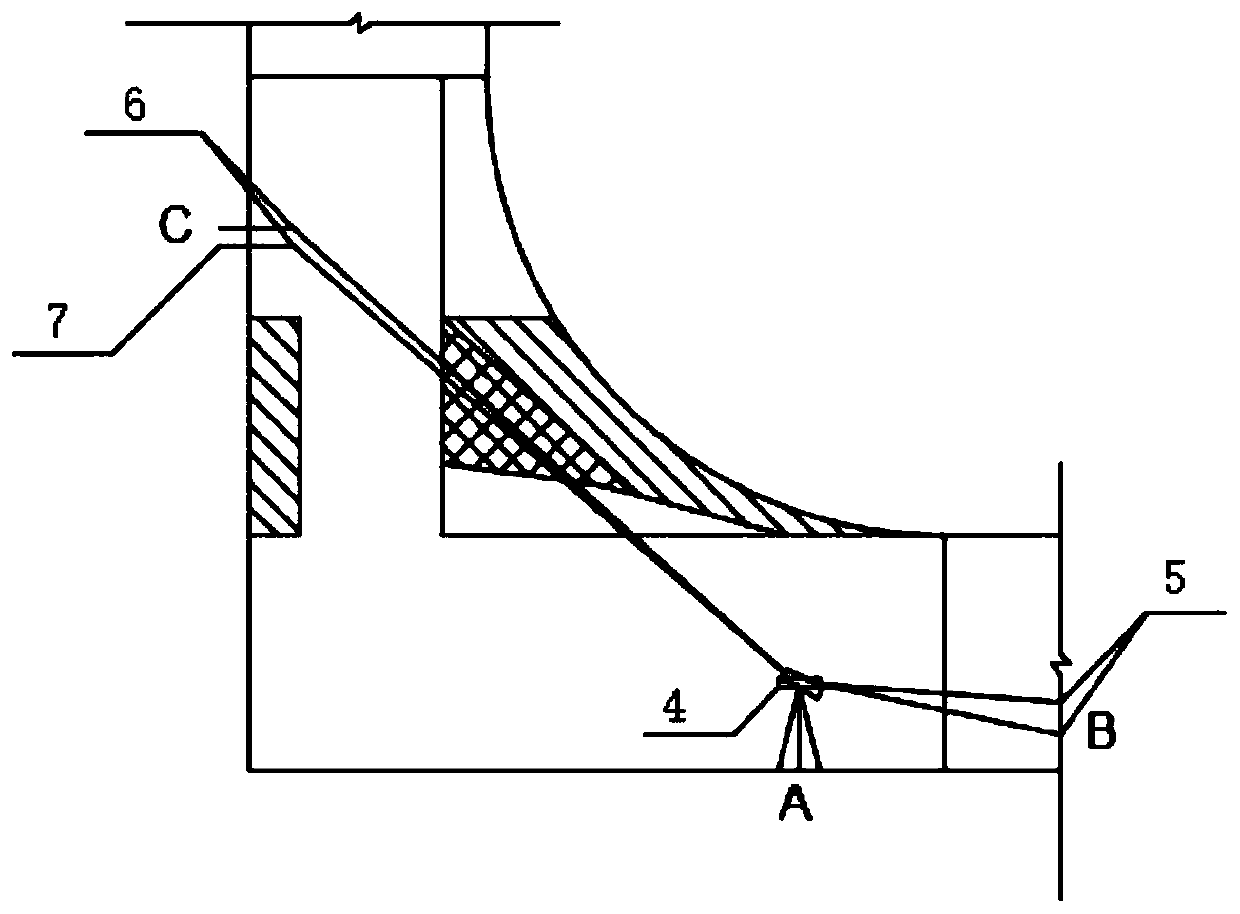

[0035] The present invention improves on the control point introduction method, mainly excavating the pilot groove 3 shape to ensure the visibility condition of the total station 4, and introducing the control point of the lower flat section of the shaft on the rear wall in the well, specifically as follows:

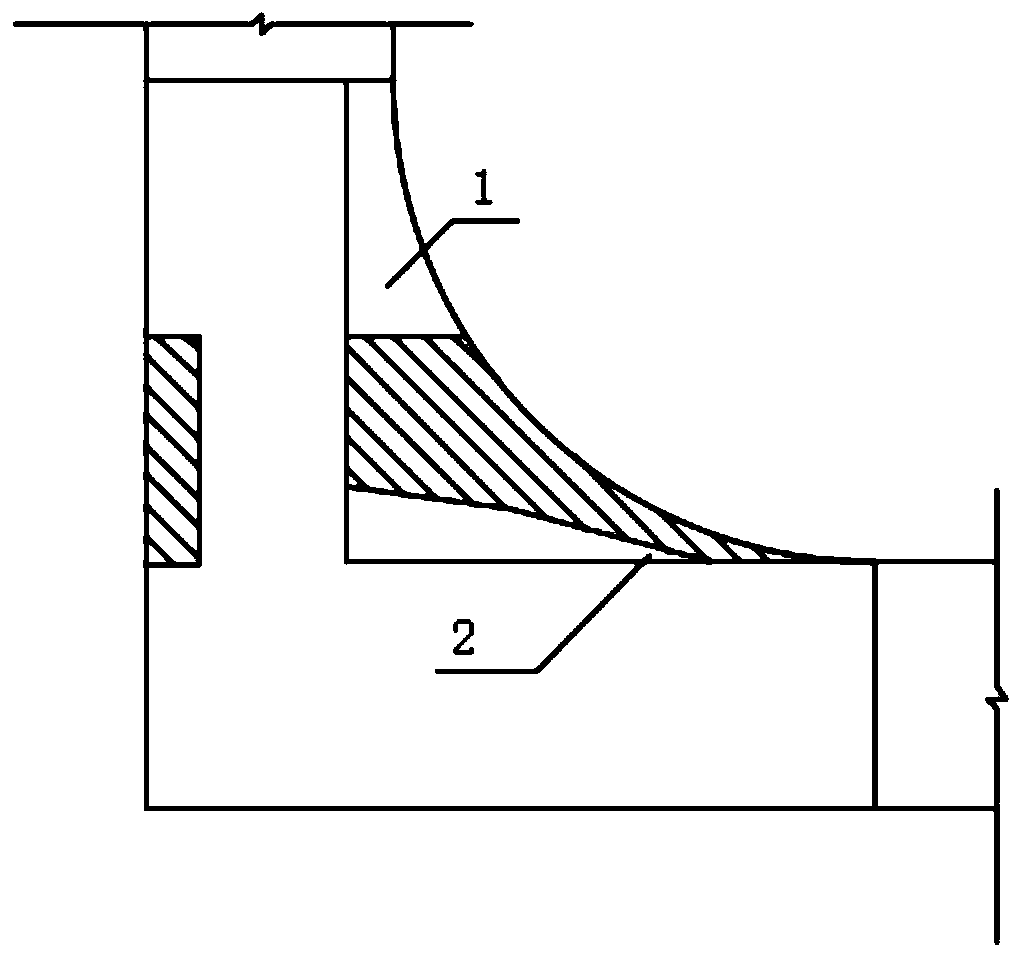

[0036] One, such as figure 1 As shown in Fig. 1 , advance excavation is carried out in both directions up and down for the curved triangular body part of the downward curved section of the vertical shaft. The upper part of the advanced excavation part 1 excavates a rock surface platform for the erection of the total station and manual operation in preparation for the subsequent measurement and setting out. Make sure that the distance from the rock face platform to the bottom of the bend is about 1 / 2 of the radius of the bend. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com