A method of setting out and distributing holes for total station

A technology of total station and hole layout, applied in the field of blasting, can solve the problems that blasting operations cannot be carried out according to the design ideas, and are not conducive to continuous improvement of blasting operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0026] In one embodiment of the present invention, comprise the following steps:

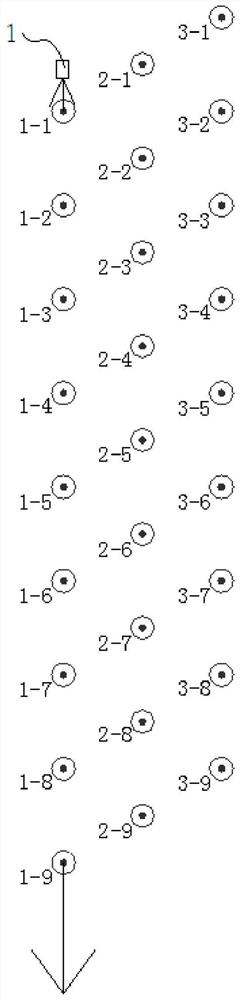

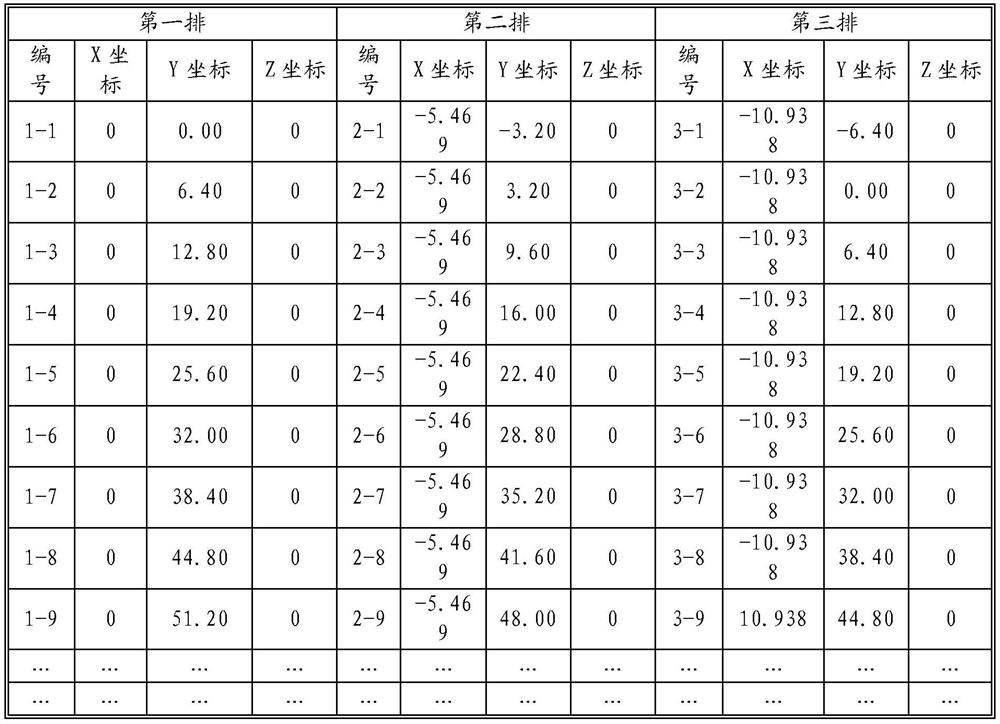

[0027] Step 1, determine the bearing area of the blasthole, and determine the minimum resistance line (determining the minimum resistance line needs to be confirmed according to the nature of the rock, the blasting material and the blasting form, the specific method is the prior art in this field, and no specific details will be made here Discussion) and determine the direction of the first row of holes and the position of the first blast hole, the first row of holes and the distance between the first row of holes and the nearest free surface is greater than or equal to the minimum resistance line;

[0028] Step 2, set up the total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com