Construction method combining static pressure pile sinking with middle-digging hole guiding for buildings or bridges

A construction method and technology for bridges, which are applied in construction, infrastructure engineering, sheet pile walls, etc., can solve the problems of large damage, long consumption time, and easy collapse of prefabricated pipe piles, so as to increase stratum adaptability and improve construction. Efficiency and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

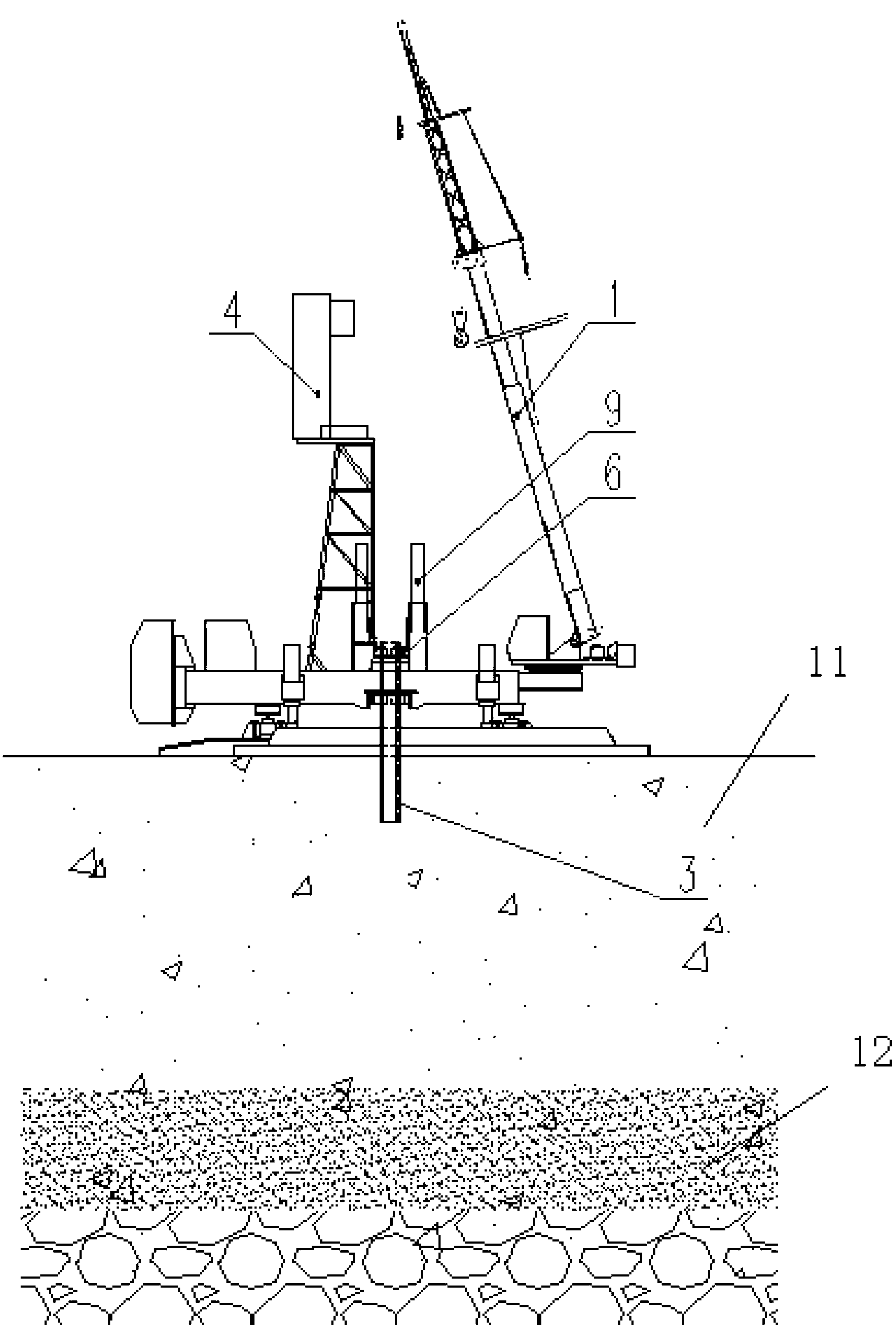

[0028] like figure 1 Shown: Drill in place. The equipment includes a static pile driver, a displaceable truss attached to the static pile driver, a power head mounted on the truss, a power head pressurization device, a rod changer for long auger rods, and a drill rod drill, application The slewing mechanism and the long and short boat traveling mechanism 7 make the center of the pile driver's mouth align with the pile position, and the displaceable mast 4 is in a displaced state. First fasten the wire rope and rigging 2 for hoisting, and lift it with the crane 1 on the pile driver. Pipe pile 3, make the clamp 6 hold the pile body tightly, and then align the center of the pile position.

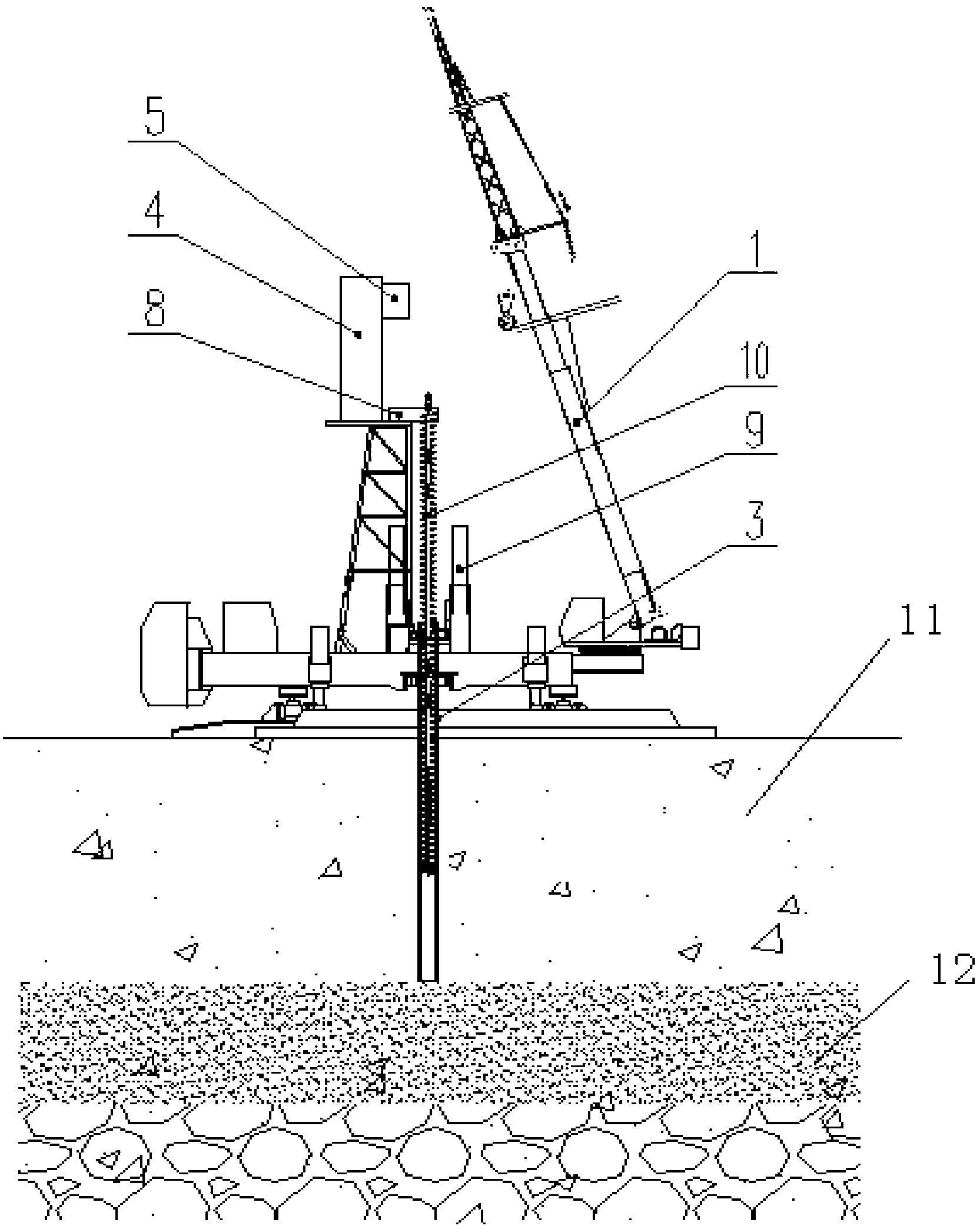

[0029] like figure 2 Shown: static pressure pile driving, connecting pile. After ensuring the verticality of the pile body, start the pile pressing oil cylinder 9, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com