A kind of high resistivity nickel wire and preparation method thereof

A technology of high resistivity and nickel wire, which is applied in the field of metal material processing, can solve the problems of unstable temperature coefficient and unusable heating wire, etc., achieve stable temperature coefficient, reduce broken wire rate, and improve tensile strength and elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

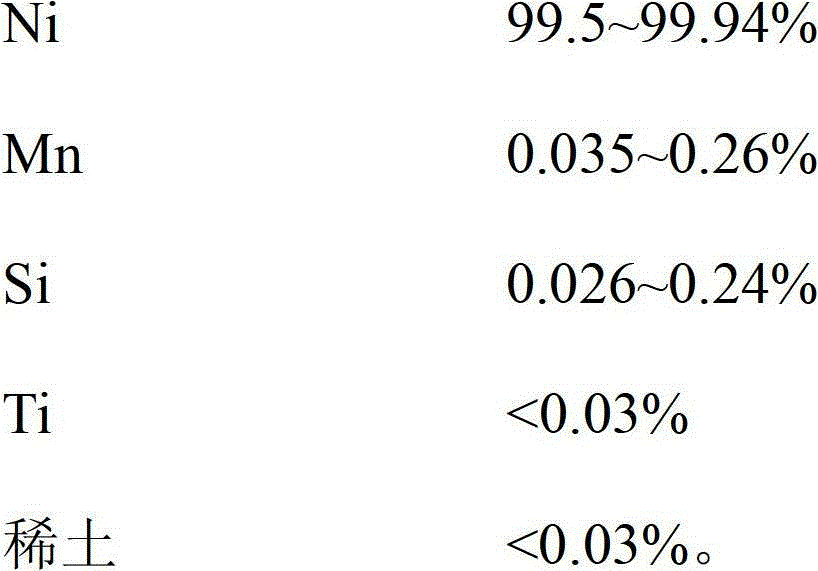

Embodiment 1

[0064] The preparation method of the nickel wire described in embodiment 1 is as follows:

[0065] (1) Mix and smelt Ni, Mn, Si, Ti, and rare earth, peel and forge the obtained ingot;

[0066] (2) After drawing the forged billet to obtain a filament with a diameter of 8.0mm, draw it again to obtain a filament with a diameter of 4.0mm, then anneal it, draw it again to obtain a filament with a diameter of 1.0mm, anneal it, and then draw it again Annealed after drawing to obtain a filament with a diameter of 0.3mm, and then annealed after drawing again to obtain a filament with a diameter of 0.15mm, and finally obtained a filament with a diameter of 0.15mm.

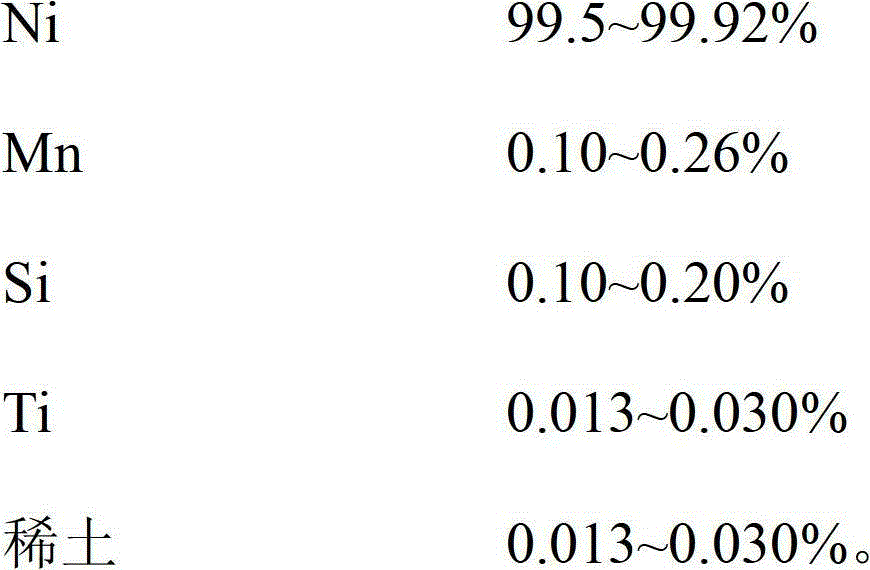

Embodiment 2

[0067] The preparation method of the nickel wire described in embodiment 2 is as follows:

[0068] (1) Mix and smelt Ni, Mn, Si, Ti, and rare earth, peel and forge the obtained ingot;

[0069] (2) Drawing the forged billet to obtain a filament with a diameter of 0.15 mm, and then annealing to obtain a nickel wire with a diameter of 0.15 mm.

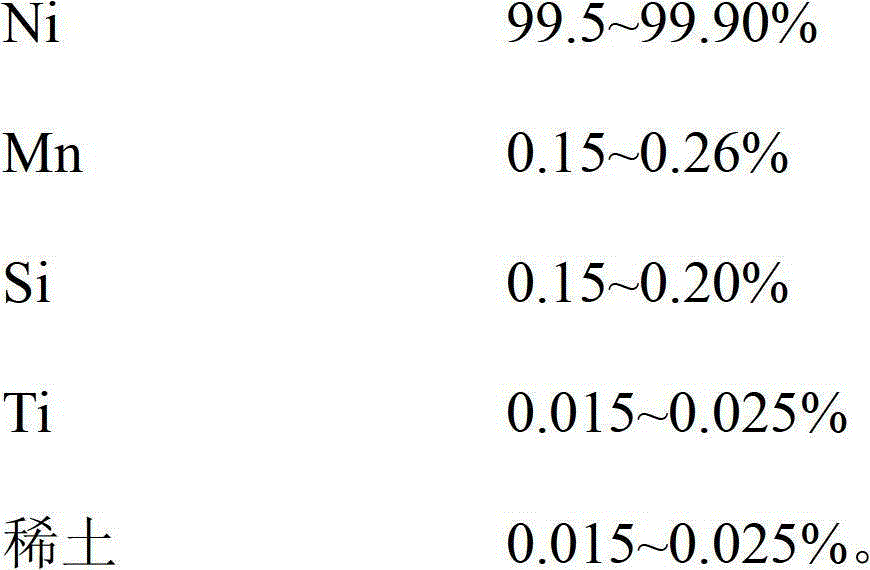

Embodiment 3

[0070] The preparation method of the nickel wire described in embodiment 3 is as follows:

[0071] (1) Mix and smelt Ni, Mn, Si, Ti, and rare earth, peel and forge the obtained ingot;

[0072] (2) After drawing the forged billet to obtain a filament with a diameter of 4.0mm, draw it again to obtain a filament with a diameter of 1.0mm, then anneal it, draw it again to obtain a filament with a diameter of 0.3mm, anneal it, and draw it again The filaments with a diameter of 0.15 mm are pulled out and then annealed to finally obtain filaments with a diameter of 0.15 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com