Composition for transparent conductive film of solar cell and transparent conductive film

A technology of transparent conductive film and solar cell, applied in conductive coatings, circuits, photovoltaic power generation, etc., can solve problems such as huge costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

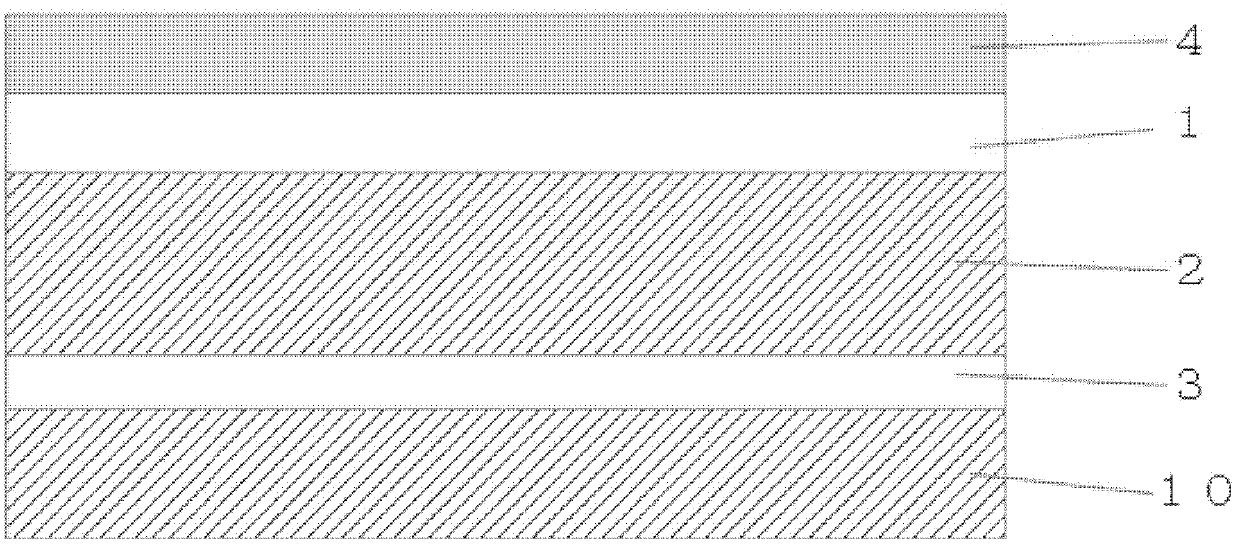

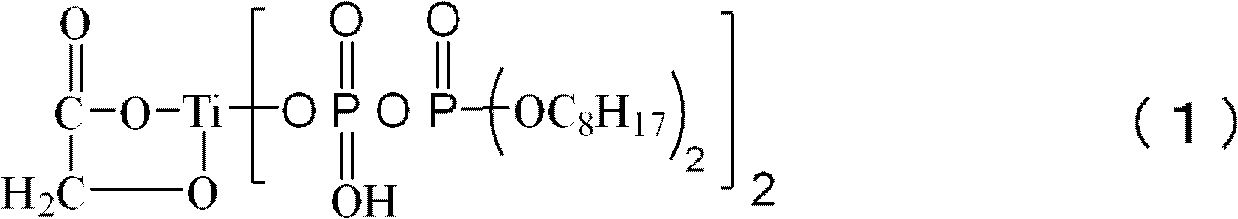

[0086] In Example 1, first, as shown in the following Table 1, in the IPA used as the dispersion medium, ITO powder with an average particle diameter of 25 nm and ITO powder with an average particle diameter of 10 nm as conductive oxide powder were mixed in a ratio of 98:2. Spherical magnesium fluoride particles 1, and, with respect to the solid particles of the total conductive oxide particles and spherical magnesium fluoride particles, SiO is mixed at a ratio of 30% by mass 2 Binder 1 acts as a binder.

Embodiment 2

[0087] In Example 2, in ethanol used as a dispersion medium, ATO powder with an average particle diameter of 40 nm and spherical magnesium fluoride particles 2 with an average particle diameter of 15 nm as conductive oxide powder were mixed at a ratio of 95:5, and , the non-polymer-type binder 1 was mixed as a binder in a ratio of 10% by mass with respect to the total solid particles of the conductive oxide particles and the spherical magnesium fluoride particles.

Embodiment 3

[0088] In Example 3, in IPA used as a dispersion medium, TZO powder having an average particle diameter of 30 nm and spherical magnesium fluoride particles 2 having an average particle diameter of 15 nm as conductive oxide powder were mixed at a ratio of 92:8, and , with respect to the solid particles of the total conductive oxide particles and spherical magnesium fluoride particles, SiO was mixed at a ratio of 30% by mass 2 Binder 2 acts as a binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com