Method for extraction of mulberry pectin via coupling of N-methyl morpholine oxide and cellulase

A technology of methylmorpholine and cellulase, which is applied in the field of coupling extraction of mulberry pectin with N-methylmorpholine oxide and cellulase, can solve the problems of low pectin extraction efficiency and improve pectin extraction Efficiency, rapid regeneration cycle, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

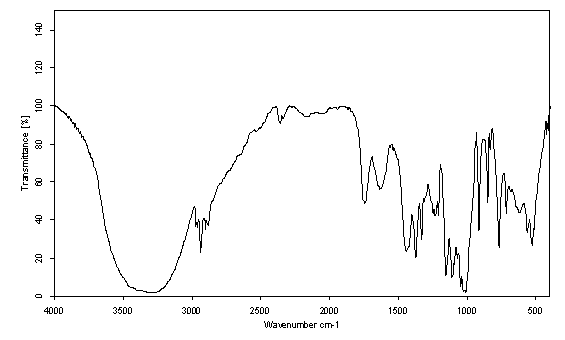

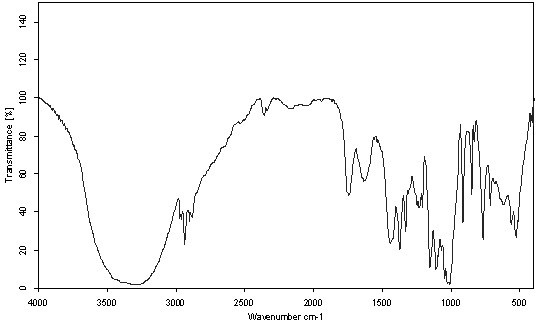

Image

Examples

Embodiment 1

[0017] N -Methylmorpholine Oxide and Trichoderma reesei Cellulase Coupling to Extract Mori Pectin

[0018] (1) Take the mulberry branch, cut off the mulberry bark with a knife, cut off the phloem, take the mulberry bark, wash away the sediment with tap water, and dry at 60°C for 1-2 hours;

[0019] (2) Take 100g of mulberry bark and add 500g of 85% concentration N - Methylmorpholine oxide (commercially available), treat mulberry bark at 50°C for 10-30 minutes, add 1-3 L of water to the system to precipitate cellulose and other materials;

[0020] (3) Take the upper liquid, add Trichoderma reesei cellulase to a final concentration of 5 FPU / mL, and treat at 45°C for 12 hours to remove cellulose impurities mixed in pectin;

[0021] (4) Add 50 g of activated carbon to the supernatant, mix and decolorize, stir for 10-30 minutes, filter to remove the activated carbon, and obtain the decolorized pectin solution;

[0022] (5) The pectin solution is distilled under reduced pressure ...

Embodiment 2

[0025] N Coupling of -Methylmorpholine Oxide and Aspergillus niger Cellulase to Prepare Mori Pectin

[0026] (1) Take mulberry branches and cut off the mulberry bark with a knife, cut off the phloem, take the mulberry bark, wash away the sediment with tap water, and dry at 60°C for 2 hours;

[0027] (2) Take 100g of mulberry bark and add 200g of 97% N -Methylmorpholine oxide, treat the mulberry bark at 90°C for 10-30 minutes, add 0.75-3 L of water to the system to precipitate materials such as cellulose;

[0028] (3) Take the upper liquid, add Aspergillus niger cellulase to a final concentration of 6 FPU / mL, and treat at 50°C for 5 hours to remove cellulose impurities mixed in pectin;

[0029] (4) Add 50 g of activated carbon to the supernatant, mix and decolorize, stir for 10-30 minutes, filter to remove the activated carbon, and obtain a decolorized pectin solution.

[0030] (5) The pectin solution passes through a 50cm-high column of strong acidic cation exchange resin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com