Low-aluminum sintered alumina-silica refractory material and preparation method thereof

A refractory material, aluminum-silicon technology, which is applied in the field of low-alumina sintered aluminum-silicon refractory materials and its preparation, and can solve problems such as the shortage of special-grade alumina and zircon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

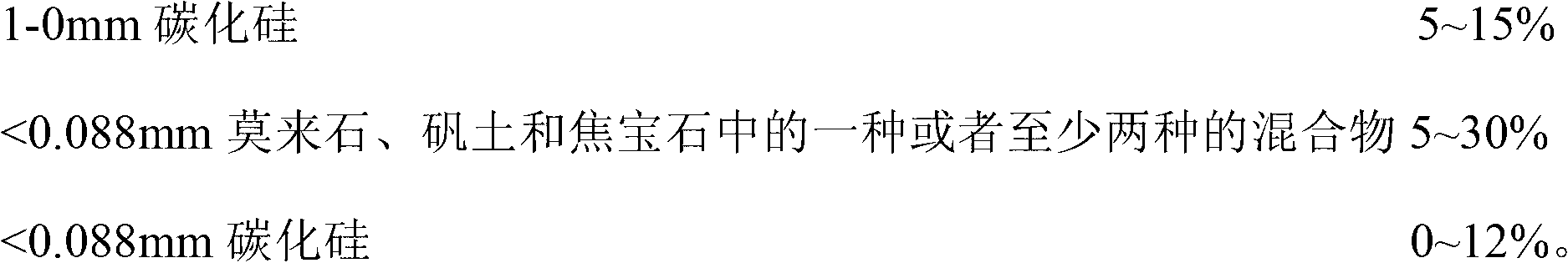

[0075] The raw materials are medium aluminum mullite with an alumina content of 56%, silicon carbide, super-grade high-bauxite micropowder with an alumina content of 85%, soft mud with an alumina content of 30%, and a 5% PVA aqueous solution as a binder. . The weight percentage formula is: 3-1mm aluminum mullite 45%, 1-0mm aluminum mullite 10%, 1-0mm SiC 13%, 3 , The apparent porosity is 20%, the compressive strength is 60MPa, the load softening temperature is 1540℃, the thermal shock stability is 20 times, and the alkali resistance is grade 1.

Embodiment 2

[0077] The raw materials are low-alumina mullite with an alumina content of 47%, silicon carbide, first-grade high-alumina bauxite micropowder with an alumina content of 80%, soft mud with an alumina content of 30%, and concentrated pulp waste liquid as a binder. The weight percentage formula is: 3-1mm low alumina mullite 35%, 1-0mm low alumina mullite 10%, 1-0mm SiC 10%, 3 , The apparent porosity is 20%, the compressive strength is 60MPa, the load softening temperature is 1450℃, the thermal shock stability is more than 30 times, and the alkali resistance is grade 1.

Embodiment 3

[0079] The raw materials are three-grade high-bauxite with 55% alumina content, silicon carbide, 800-mesh super-grade high-bauxite micropowder with 85% alumina content, soft mud with 30% alumina content, and sulfurous acid pulp waste liquid as a combination agent. The weight percentage formula is: 3-1mm tertiary bauxite 35%, 1-0mm tertiary bauxite 10%, 1-0mm SiC 10%, 3 , The apparent porosity is 19%, the compressive strength is 55MPa, the load softening temperature is 1400°C, the thermal shock stability is 15 times, and the alkali resistance is first class.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com