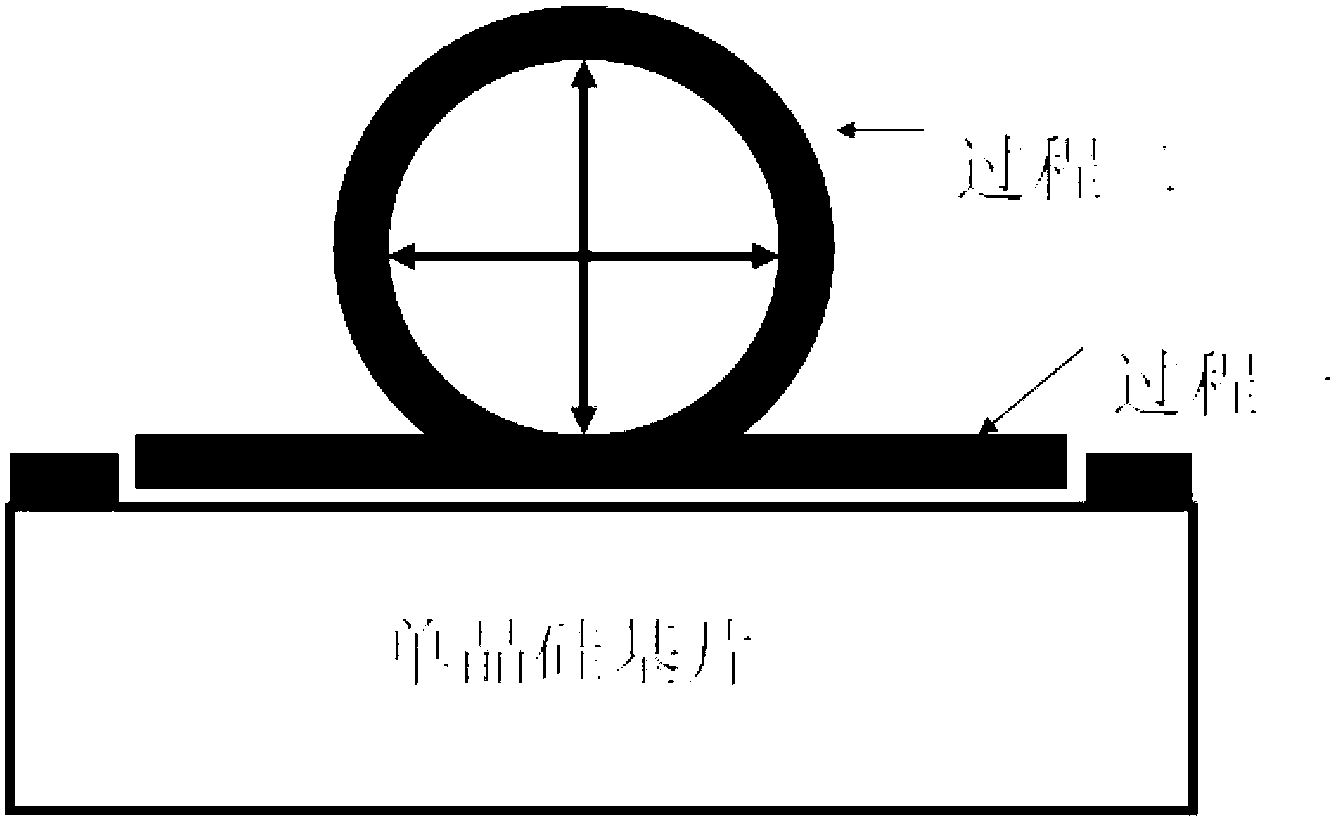

Porous silicon micron tube and preparation method thereof

A technology of porous silicon and micro-tubes, applied in separation methods, chemical instruments and methods, microstructural technology, etc., can solve problems such as deterioration and poor mechanical stability of porous silicon, and achieve simple process, good mechanical properties and operability. The effect of stability and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] In order to illustrate the fracture phenomenon of the porous silicon layer, we design the following experiment: the silicon substrate is a p-type silicon wafer polished on one side, (100) crystal plane, and the resistivity is 5-10Ω·cm. The standard cleaning process for integrated circuits, the RCA process, is used. The specific cleaning methods and functions are as follows:

[0028] The first step is to soak in deionized water for 5 minutes, then concentrated sulfuric acid: hydrogen peroxide = 3: 1, cook at 75-85°C for 10 minutes, the main purpose is to remove organic matter;

[0029] The second step, soak in deionized water for 5 minutes, ammonia water: hydrogen peroxide: deionized water = 1:4:20 (No. 1 liquid), boil at 75-85°C for 10 minutes, the main purpose is to remove tiny particles

[0030] The third step is to soak in deionized water for 5 minutes, concentrated hydrochloric acid: hydrogen peroxide: deionized water = 1:1:6 (No. 2 solution), and boil for 10 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com