Wave prevention device in tank body of tank truck, and tank truck with wave prevention device

A liquid tank truck and tank body technology, which is applied in the field of liquid tank trucks, can solve the problems of increased hardness at the welding part of the tank body, unable to achieve the effect of blocking waves, and reducing the service life of the tank body, so as to achieve uniform load distribution and improve the wave blocking coefficient. , the effect of reducing the impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

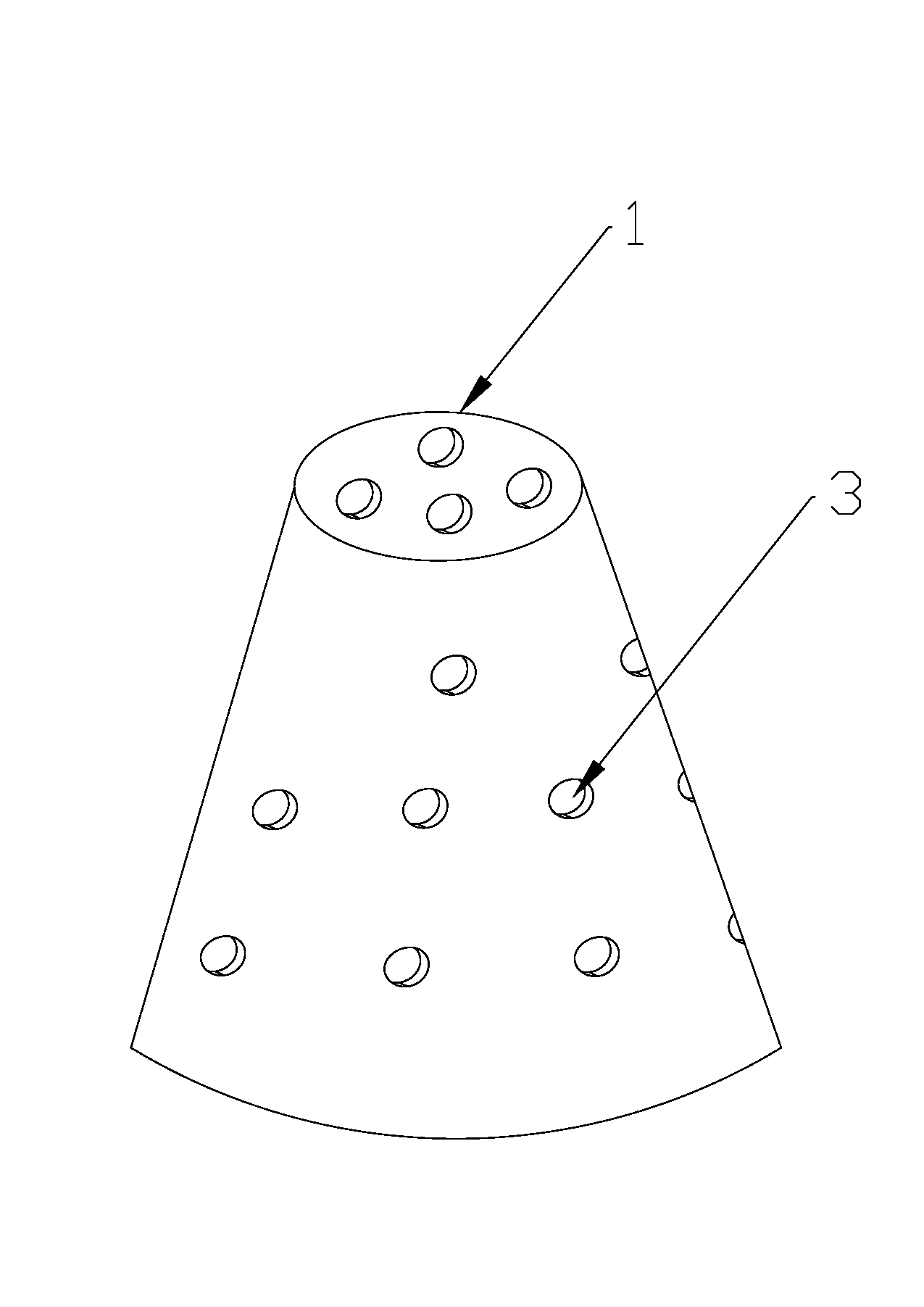

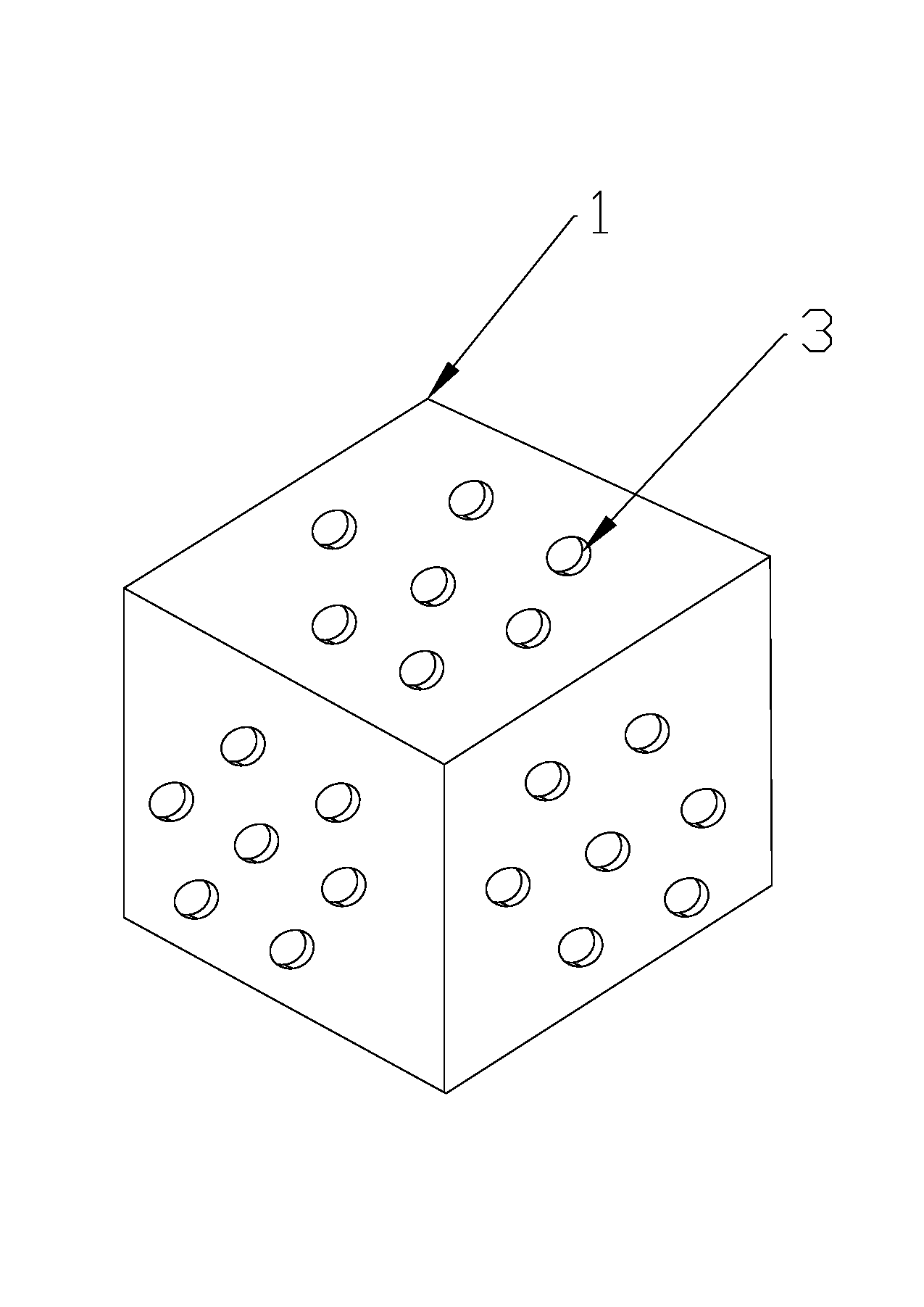

[0040] Embodiment 1 of the wave arresting device of the tank body of the liquid tank truck of the present invention is as follows: Figure 1 to Figure 7 As shown, a housing 1 with a cavity is included, and a through hole 3 is opened on the outer surface of the housing 1 .

[0041] The shape of the housing 1 is set to any one of sphere, square, cylinder, cone, triangular pyramid and quadrangular pyramid, wherein a preferred shape is a spherical shape.

[0042] Specifically, the shell 1 is made of polyamide fiber, thermoplastic resin, plastic or rubber material, or other elastic synthetic polymer materials. When in use, the wave blocking device is suspended above the liquid in the tank.

[0043] Wherein, the thermoplastic resin material is polyethylene resin or polypropylene resin;

[0044] The plastic material is polytetrafluoroethylene;

[0045] The rubber material is nitrile rubber, fluororubber or peroxide vulcanized fluororubber.

[0046] Specifically, the through holes ...

Embodiment 2

[0050] The anti-wave device of the tank body of the liquid tank truck of the present embodiment is as follows: Figure 5 , Figure 6 and Figure 7 As shown, on the basis of Embodiment 1, the features not explained in this embodiment adopt the explanation in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0051] The shell 1 of the wave blocking device is shaped as a sphere, and the sphere includes an upper hemisphere 11 , a lower hemisphere 12 , and a locking device 2 connecting the upper hemisphere 11 and the lower hemisphere 12 . Among them, the structure of the upper hemisphere 11 and the lower hemisphere 12 is easier to process than the structure of the whole sphere.

[0052] see Figure 6 and Figure 7 , the locking device 2 includes a hook 21 arranged on the upper hemisphere 11, a block 22 arranged on the lower hemisphere 12, and a stopper 23 for blocking the sliding of the hook 21, and the hook 21 is engaged...

Embodiment 3

[0059] Embodiment 3 of a liquid tank truck of the present invention is as Figure 8 As shown, there is a tank body 4, the front and rear ends of the tank body 4 are respectively welded with a head 5, the tank body 4 is provided with a wave breaking plate 6, and the two ends of the wave breaking plate 6 are welded to the inner wall of the tank body 4, and the resistance The corrugated plate 6 plays the effect of breaking waves in the longitudinal or transverse one-dimensional direction of the tank body.

[0060] Specifically, the wave-breaking board 6 is a wave-shaped or dish-shaped wave-breaking board 6 .

[0061] Specifically, the tank body 4 is provided with a plurality of wave resistance devices. According to the needs of the liquid tanker, the number of wave resistance devices can be increased, and the size and shape of the wave resistance devices can be designed to improve the wave resistance coefficient.

[0062] The structure of the wave blocking device of this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com