Continuous pultrusion manufacturing method and production device for fibrous composite drive shaft

A technology of fiber composite material and manufacturing method, which is applied in the field of continuous pultrusion manufacturing method of fiber composite transmission shaft and its production device, can solve the problems of difficult control of glue content, poor strength and stiffness, and low production efficiency, and achieve Avoid the difficult control of glue content, improve the axial stiffness, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

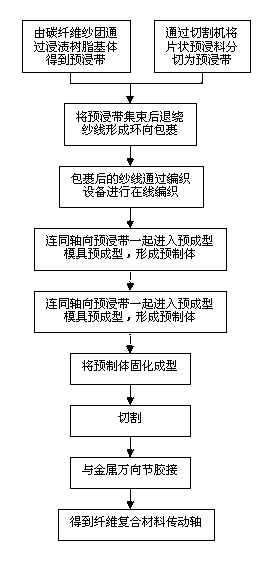

[0054] like figure 1 As shown, this embodiment provides a continuous pultrusion manufacturing method for a fiber composite transmission shaft, including the following production steps:

[0055] The preparation of the prepreg tape, the prepreg tape is obtained by impregnating the resin matrix from the carbon fiber yarn cluster;

[0056] The mold is preformed, and the prepreg tape is unwound by the hoop winding disc at a winding angle of 30° to form a hoop wrap. The wrapped yarn is woven online through two braiding rollers, and enters the temperature together with the axial prepreg tape. Preforming a preforming mold at 80°C to form a preform;

[0057] Curing molding, the prefabricated body preformed by the preforming mold enters the curing molding mold with three stages of heating, namely heating, gelling and curing, to form the transmission shaft rod;

[0058] Mechanical processing, pull the transmission shaft rod out of the solidified molding mold at a traction speed of 10cm...

Embodiment 2

[0070] like figure 1 As shown, a continuous pultrusion manufacturing method of a fiber composite transmission shaft comprises the following production steps:

[0071] Preparation of the prepreg tape, the sheet prepreg material is cut into prepreg tapes with a width of 4-12mm by a cutting machine;

[0072] The mold is preformed, and the prepreg tape is unwound by the hoop winding disc at a winding angle of 70° to form a hoop wrap. The wrapped yarn is woven online through two braiding rollers, and enters the temperature together with the axial prepreg tape. Preforming the preforming mold at 150°C to form a prefabricated body;

[0073] Curing molding, the prefabricated body preformed by the preforming mold enters the three-stage heating curing molding mold for curing molding to form a transmission shaft rod;

[0074] Mechanical processing, pulling the transmission shaft rod out of the solidified molding mold at a traction speed of 30cm / min through the traction mechanism, cuttin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com