Method for preparing Zr-based hydrophilic chromatographic packing Zr/Si HILIC

A hydrophilic chromatography, zirconium-based technology, used in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor permeability of fillers, difficult to uniform particles, and unsatisfactory pore structure, and achieve ideal pore structure, uniform particles, and good pore structure. Effects of chemical and mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

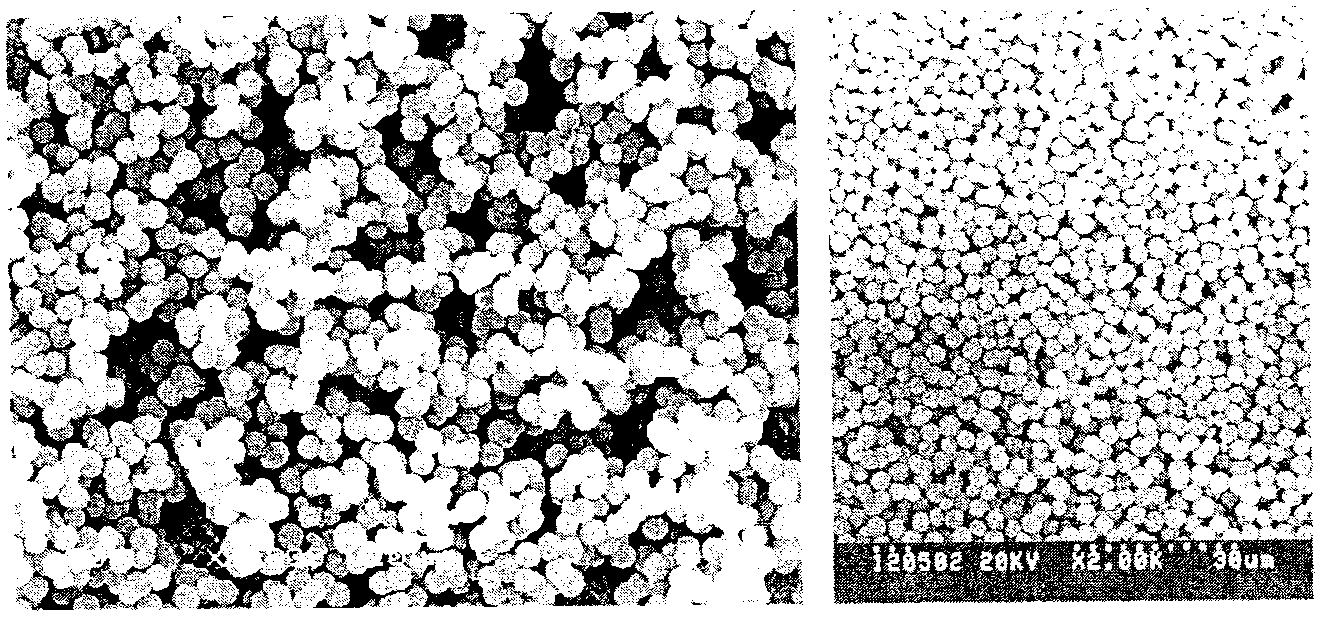

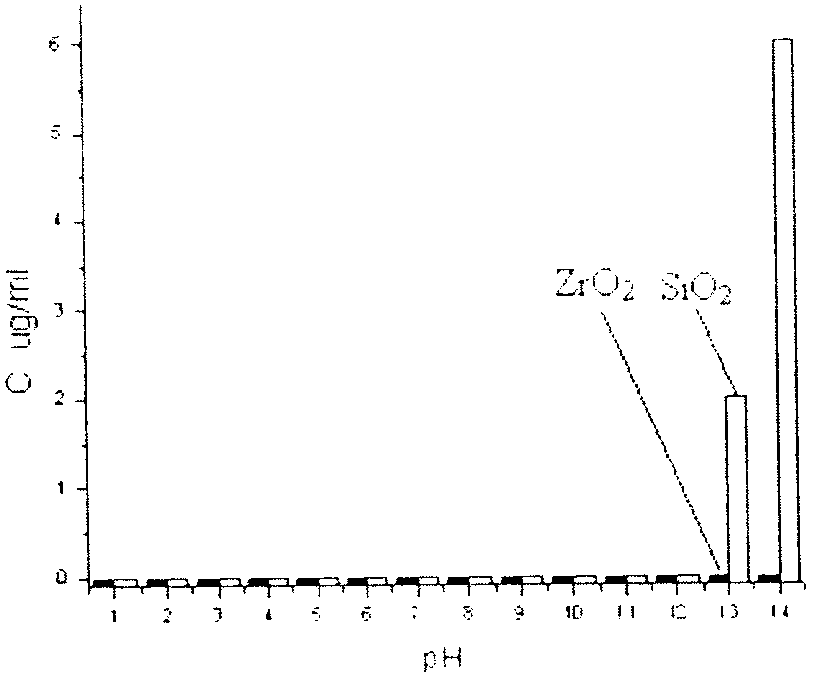

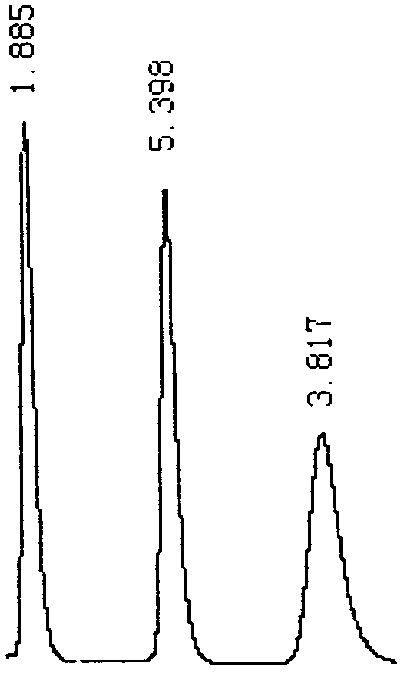

[0019] The carefully screened silica gel microspheres with a particle diameter of 3.49 μm (s=0.302) were placed in 6 mol / L hydrochloric acid and ultrasonicated for 0.5 h for activation pretreatment, suction filtered, washed and dried. The activated pretreated silica gel microspheres were put into 6mmol / L SDS solution, ultrasonicated for 0.5h, and a layer of surfactant SDS molecular film was adsorbed on the surface of the silica gel microspheres. After suction filtration, washing, and drying, a film on the surface of the silica balls was obtained. A layer of surfactant complex (SiO 2 -SDS). Then the composite SiO 2 -SDS was put into 0.1mol / L zirconium solution, and ultrasonic treatment was performed at constant temperature for 1.5 hours in a water bath at 60°C to assemble a layer of nano-zirconium film on the surface of the composite microspheres to obtain SiO 2 -SDS-ZrO 2 Composite microspheres, let stand, filter with suction, and dry. The SDS film and the zirconium film w...

Embodiment 2

[0023] The carefully screened silica gel microspheres with a particle diameter of 3.49 μm (s=0.302) were placed in 6 mol / L hydrochloric acid and ultrasonicated for 0.5 h for activation pretreatment, suction filtered, washed and dried. Put the activated and pretreated silica gel microspheres into a 6mmol / L SDS solution and sonicate for 0.5h, adsorb a layer of surfactant SDS molecular film on the surface of the silica gel microspheres, and filter, wash, and dry to obtain a film on the surface of the silica balls. A layer of surfactant composite SiO 2 -SDS. Then the composite SiO 2 -SDS spheres are put into zirconium sol for self-assembly, and subjected to constant temperature ultrasonic treatment for 1.5 hours under the condition of 60°C water bath, suction filtration, washing and drying, and a layer of nano-zirconia particle film can be assembled on the surface of silica gel spheres. So repeated coating of SDS film and ZrO 2 Film 4 times. After burning at 600°C, the core-sh...

Embodiment 3

[0027] The carefully screened silica gel microspheres with a particle diameter of 3.49 μm (s=0.302) were placed in 6 mol / L hydrochloric acid and ultrasonicated for 0.5 h for activation pretreatment, suction filtered, washed and dried. Put the activated pretreated silica gel microspheres into the zirconium sol and magnetically stir for 1.5h for self-assembly, and obtain a composite SiO with a layer of zirconia nanoparticles assembled on the surface of the silica spheres. 2 -ZrO 2 , suction filtration, washing, and drying; repeat the above operation four times. After burning at 500℃, the core-shell type ZrO can be prepared 2 / SiO 2 microspheres, the ZrO 2 / SiO 2 After further screening of microspheres, Zr / Si HILIC was obtained, and its composition is shown in Table 3.

[0028] The ZrO that table 3 embodiment 3 prepares 2 / SiO 2 Composition of microspheres

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com