Device for catalytic denitration reaction by preheating waste incineration flue gas

A technology for catalytic denitrification and waste incineration, which can be applied to combined devices, chemical instruments and methods, and dispersed particle separation. The effect of filtering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

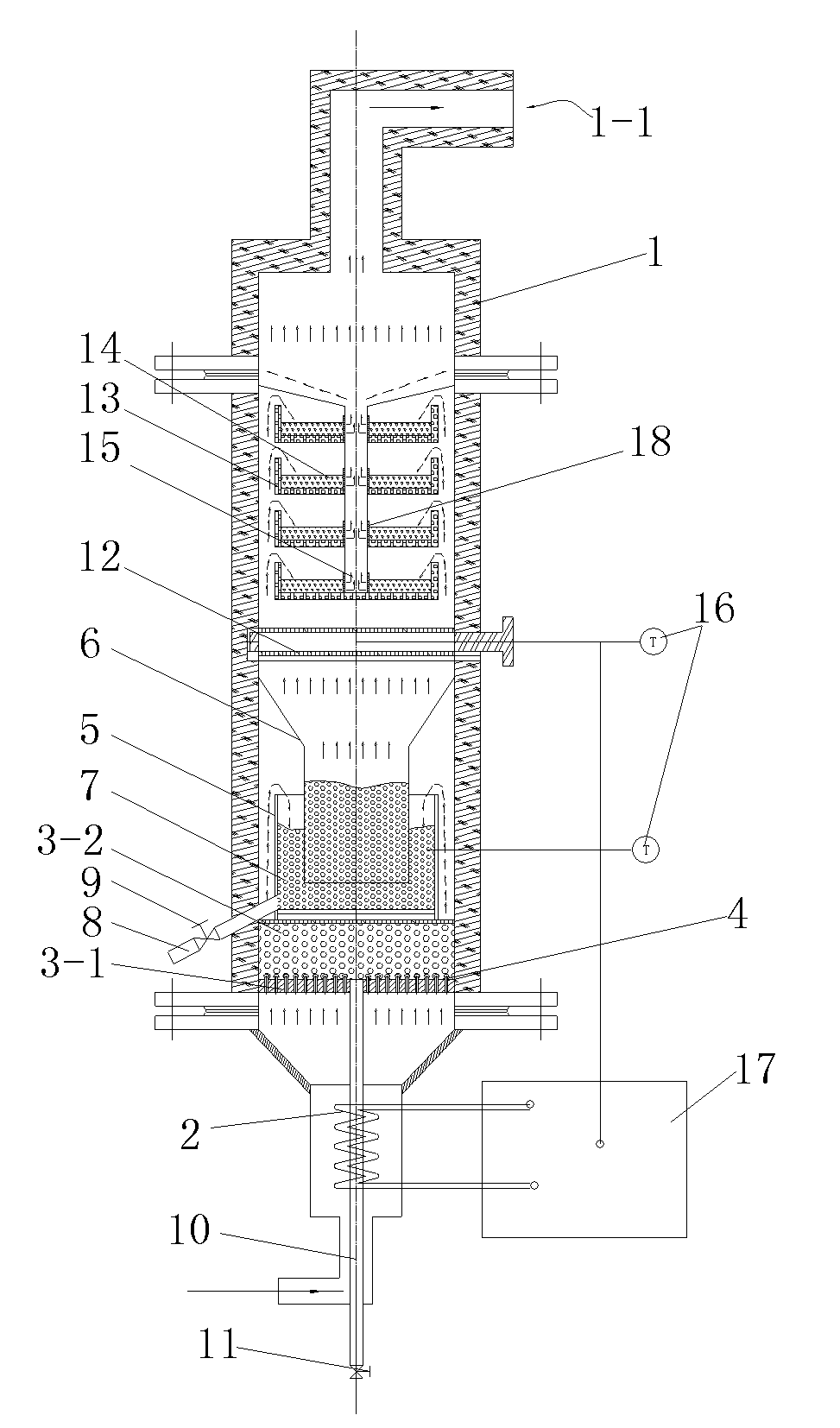

[0018] Example 1 of waste incineration flue gas preheating catalytic denitration reaction device, such as figure 1 As shown, there is a housing 1 which is cylindrical and divided into two sections, an upper half section and a lower half section. The upper half section and the lower half section are flange-connected, and a two-section housing 1 is adopted. The parts inside the housing 1 can be easily replaced. The upper end of the upper half section is provided with a clean flue gas outlet 1-1 for the treated clean flue gas to discharge, and the lower end of the lower half section is provided with a corresponding flue gas outlet 1-1. In the flue gas inlet, the casing 1 is provided with an air flow channel between the flue gas inlet and the clean flue gas outlet 1-1; the lower end of the casing 1 is provided with a pre-heating unit at the flue gas inlet. The heating unit is used for pre-heating the flue gas entering the air flow channel to improve its catalytic reaction efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com