Glass fiber reinforced plastic radome and preparation method thereof

A glass fiber reinforced plastic radome and glass microbead technology, which is applied in the field of metamaterials, can solve the problems of inability to meet the performance requirements in the electromagnetic field, the dielectric constant and loss of glass fiber reinforced plastic, etc., to improve the interface bonding force, improve the mechanical properties, and enhance the bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

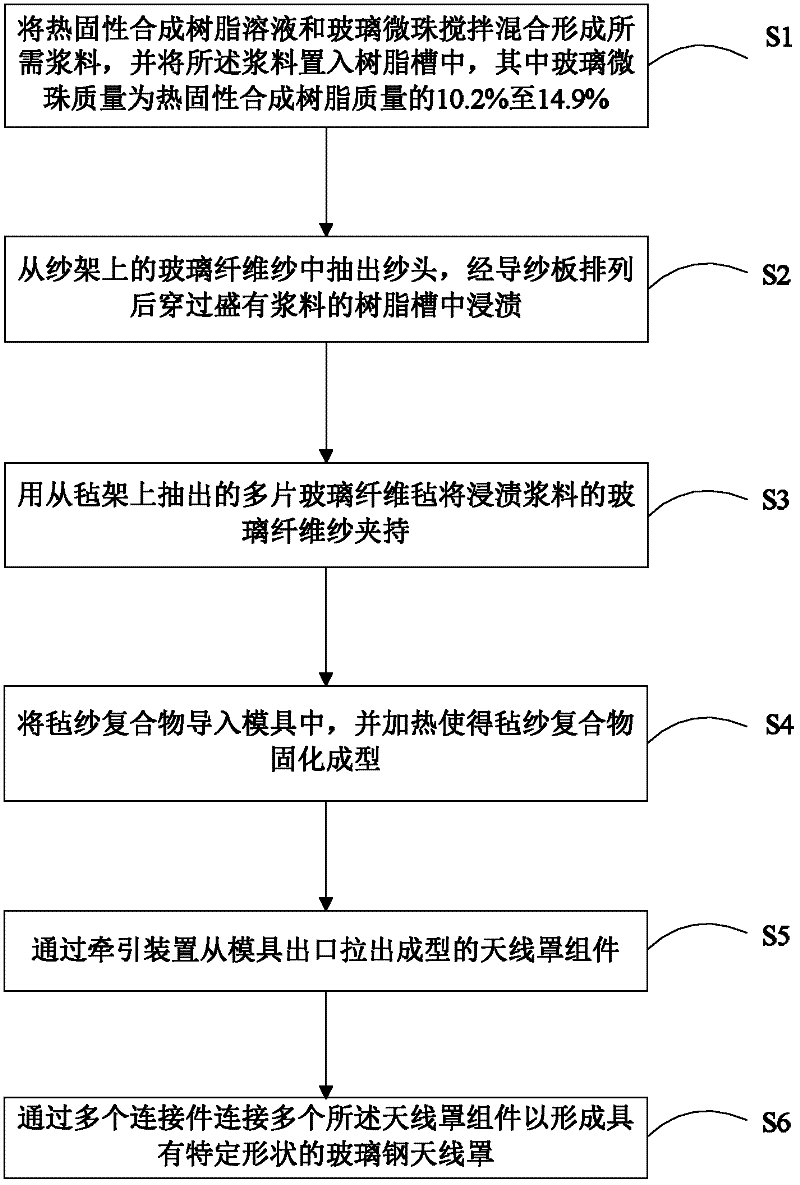

Method used

Image

Examples

Embodiment Construction

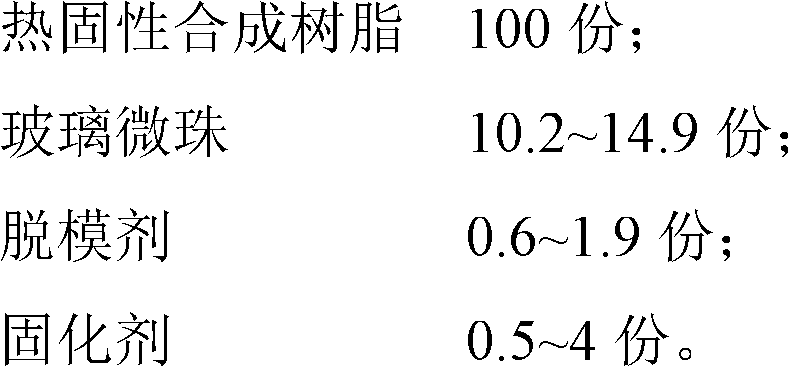

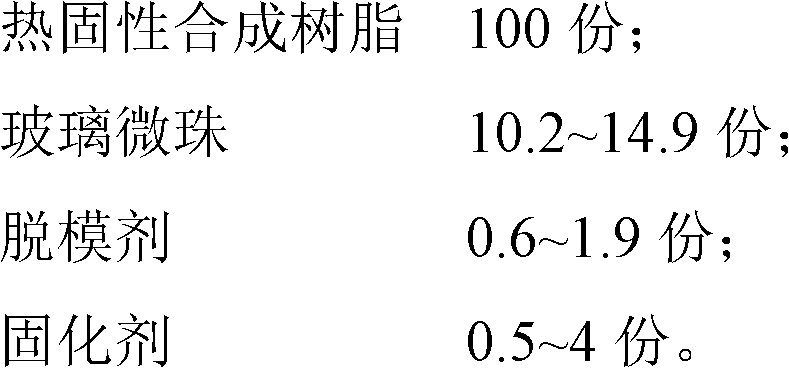

[0023] The invention provides a glass fiber reinforced plastic radome. The glass fiber reinforced plastic radome includes the following raw materials in parts by mass:

[0024]

[0025] In a preferred embodiment, the number of glass beads in FRP can be selected as 10.2 parts, 10.5 parts, 11 parts, 11.5 parts, 12 parts, 12.5 parts, 13 parts, 13.5 parts, 14 parts, 14.5 parts, 14.9 parts. The selection of the thermosetting synthetic resin can be referred to above, preferably unsaturated polyester resin, epoxy resin and the like. Curing agent and accelerator can choose the appropriate curing system according to the resin. Test the electrical properties and the mechanical properties of the beautifying radome prepared when the present invention adopts the glass beads of different mass ratios, the test frequency is 1.7GHz, and the thickness is 4mm. The results are as follows:

[0026]

[0027] It can be seen from the above results that when the mass percentage of the glass mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com