Modified lithium manganate positive pole material and preparation method thereof

A cathode material, lithium manganate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problem that high temperature cycle performance is not significantly improved, and achieve the effect of improving normal temperature cycle performance, reducing dissolution, and good high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

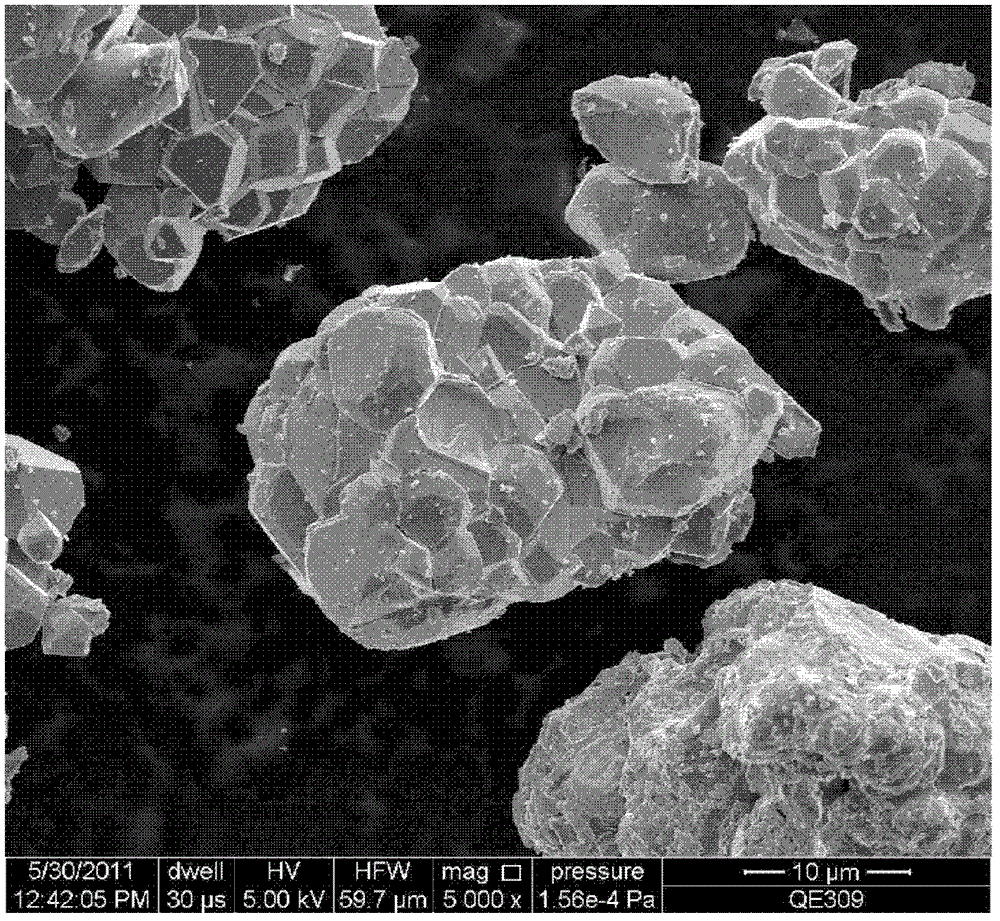

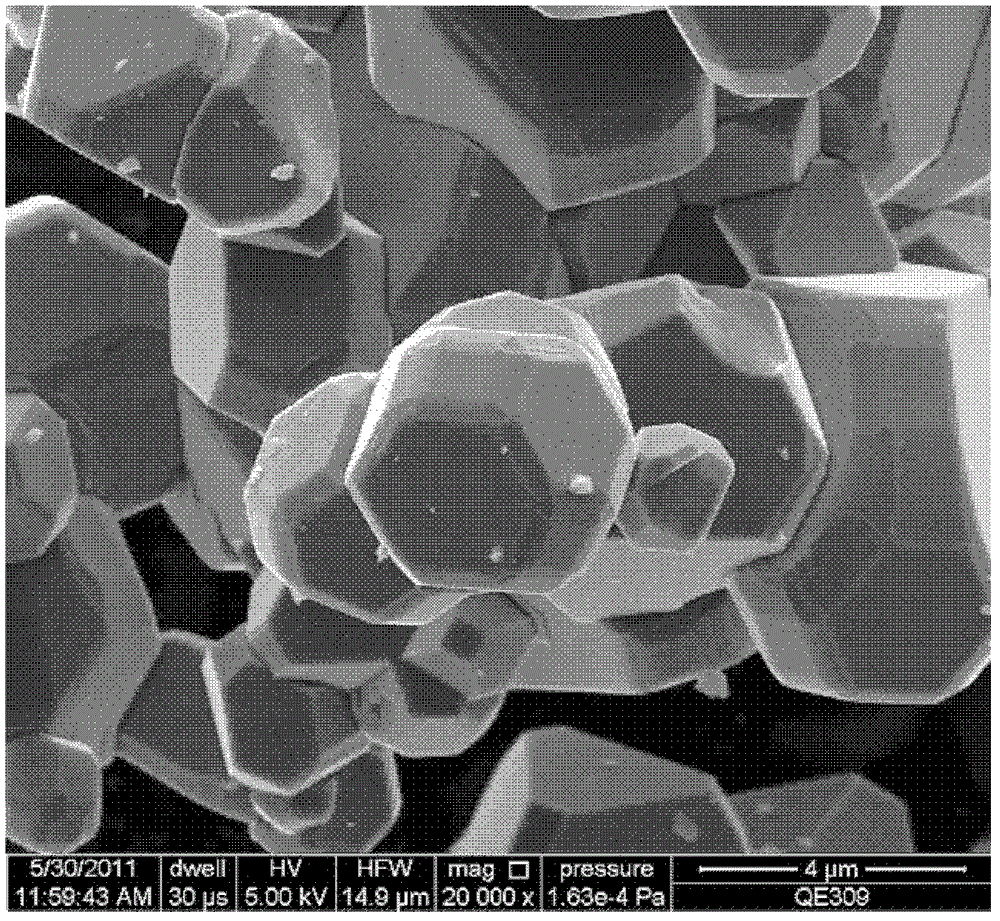

Image

Examples

preparation example Construction

[0066] The present invention also provides a method for preparing the modified lithium manganate positive electrode material described in the above technical solution, comprising the following steps:

[0067] a) Preheating after mixing manganese-containing compound, lithium-containing compound and A-containing compound to obtain the first sintered body, wherein A is Li, Na, Mg, Ti, V, Cr, Fe, Mn, Co, Ni, One or more of Cu, Zn, Zr, Nb, Ce, Nd and Dy;

[0068] b) mixing the first sintered body obtained in step a) with a compound containing M and then firing to obtain a second sintered body, wherein M is one or more of B, Al, Ga and In;

[0069] c) Annealing the second sintered body obtained in the step b) to obtain a modified lithium manganate positive electrode material.

[0070] In the present invention, the manganese-containing compound, the lithium-containing compound and the A-containing compound are firstly preheated, so that A replaces part of the Mn element to form a ma...

Embodiment 1~10

[0091] According to the raw materials, dosage and conditions shown in Table 1, the lithium manganate material was prepared according to the following steps:

[0092] Uniformly mixing manganese-containing compound, lithium-containing compound and A-containing compound, preheating, cooling, and grinding to obtain the first sintered body; mixing the obtained first sintered body with M-containing compound, roasting, cooling, and grinding to obtain the first sintered body A second sintered body: annealing the obtained second sintered body, and cooling to room temperature to obtain a modified lithium manganate positive electrode material.

[0093] Table 1 The formula and conditions for preparing the modified lithium manganate cathode material in Examples 1-10 of the present invention

[0094]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com