Tylosin gene engineering strain and application thereof

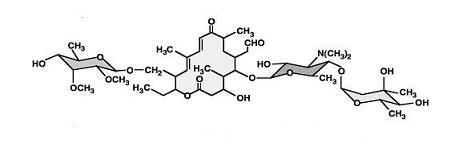

A technology of genetically engineered bacteria and tylosin, which is applied in the field of genetic engineering and bio-fermentation industry, can solve the problem that tylosin products do not meet the standards of Veterinary Pharmacopoeia, the content of component A of tylosin is low, and the content of component C is not Easy transformation and other problems, to achieve the effect of reducing the difficulty of separation and purification, reducing production costs, and long breeding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

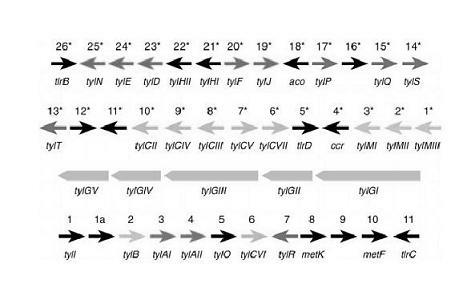

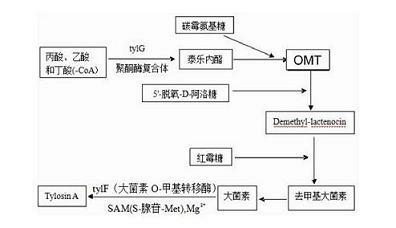

[0031] Construction of Genetic Engineering Bacteria TL-209

[0032] Design primers to PCR clone TylF gene and VHb gene respectively

[0033] PT1: 5'-GTGGCACCTTCCCCGGACCACGCC-3'

[0034] PT2: 5'-TCAGCCGCTGTGCCGCCAATAGG-3'

[0035] PV3: 5'-CGGGATCCATATGCTGGACCAGCAAACCAT-3'

[0036] PV4: 5'-CGGGATCCTTTATTCAACCGCTTGAT-3'

[0037] The PCR product was recovered from agarose gel, and then double-digested with the expression vector pFC119. After recovery, TylF-VHb and pFC119 were ligated with T4 DNA ligase at 16°C for 2 hours to construct a recombinant expression vector pFC120 (such as figure 2 ). Then pour into Escherichia coli ET12567 competent cells, activate and culture in LB medium for 1 hour, spread on the ampicillin-resistant plate, pick the transformant, extract the plasmid for verification, and then transfer the recombinant expression vector pFC120 Introduce Streptomyces flexneri.

[0038] Specific steps are as follows:

[0039] (1) Pick ET12567 / pUZ8002 monoclonal and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com