Weather resistant type color co-extruding dedicated material with pearly-luster decoration effect and manufacturing method thereof

A decorative effect and special material technology, which is applied in the field of weather-resistant color co-extrusion special material with pearlescent decorative effect and its manufacturing field, can solve the problems of inability to adapt to decorative diversification, fading, poor decorative effect, etc., and achieve gorgeous colors and weather resistance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

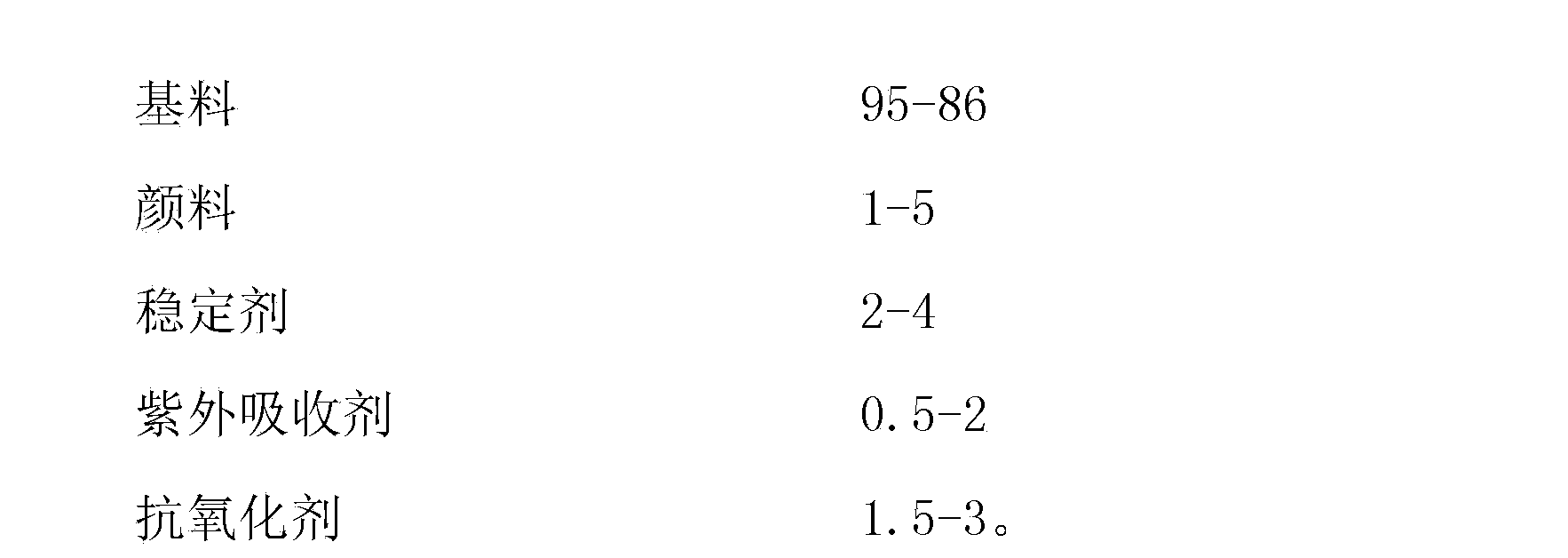

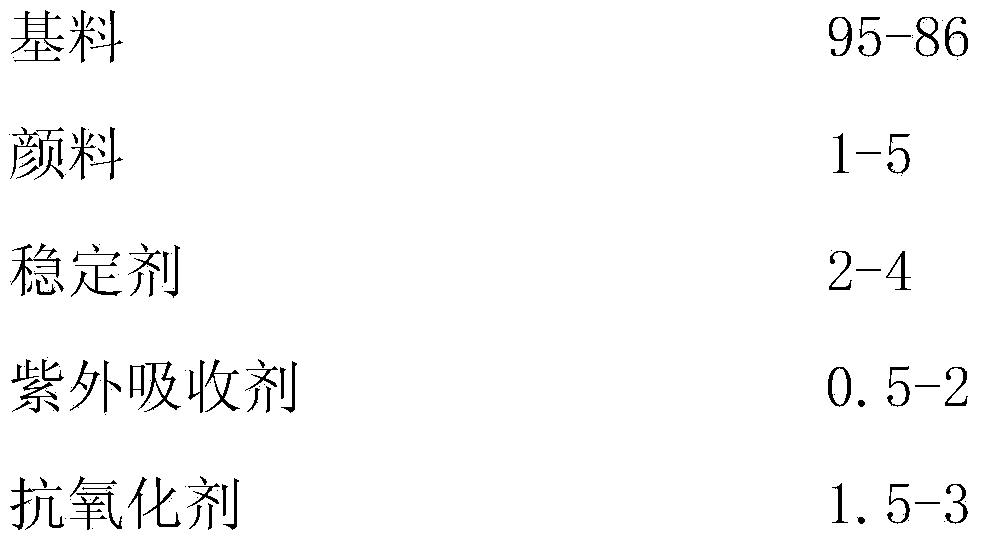

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a weather-resistant color co-extrusion special material with bronze pearlescent decorative effect, which contains 92.7% of base material LI970 ASA, 1.3% of pigment, 3% of UV770DF light stabilizer, 1% of UV326 ultraviolet absorber, and B215 compound anti- Oxygen agent 2%. The specific pigment weight percentages are: carbon black 1.9%, color metallic luster effect pigment 56.2%, iridescent two-color pearl effect pigment 41.9%.

[0033] The preparation method of the above-mentioned weather-resistant color co-extrusion special material with pearlescent decoration effect includes the following steps:

[0034] (1) Weighing: Weigh the base materials, pigments, stabilizers, UV absorbers, and antioxidants according to the formula.

[0035] (2) Mixing: In order to make the mixing uniform, first mix the pigment, stabilizer, ultraviolet absorber, and antioxidant evenly, then add the base material and mix uniformly in a low-speed mixer. The mixing time is 10-15min...

Embodiment 2

[0041] This embodiment provides a weather-resistant color co-extrusion special material with silver pearlescent decoration effect and a preparation method thereof. The weight percentages of the components are: base material V150 90.3%, pigment 3.7%, UV770DF light stabilizer 3%, UV326 UV absorber 1%, B215 compound antioxidant 2%. The specific pigment weight percentages are: silver-white pearl luster effect pigment 81.6%, aluminum powder 18.4%.

[0042] The above-mentioned raw materials are extruded and pelletized on a single-screw extruder to obtain a weather-resistant color co-extrusion special material with silver pearlescent decorative effect. The production process and process are basically the same as in Example 1.

[0043] The technical effects are as follows:

[0044] ①After processing into a film, it can be observed to have a shiny appearance with a silver pearl effect

[0045] ②Color difference after aging △E ≤5, △b≤3 (Method A in GB / T 16422.2-1999, 6000h test)

Embodiment 3

[0047] This embodiment provides a weather-resistant color co-extrusion special material with silver pearlescent decorative effect and a preparation method thereof. The weight percentages of the components are: base material V150 89.3%, pigment 3.7%, UV770DF light stabilizer 3%, UV326 UV absorber 1%, B215 compound antioxidant 2%. The specific pigment weight percentages are: silver-white pearl luster effect pigment 81.6%, aluminum powder 18.4%, and 1% 2,6-dihydroxyacetophenone.

[0048] In the preparation method, 2,6-dihydroxyacetophenone and B215 are added at the same time. The rest is the same as in Example 1.

[0049] The technical effects are as follows:

[0050] ①Glossiness≤20;

[0051] ② Color difference after aging △E ≤4, △b≤2 (A method in GB / T 16422.2-1999, 6000h test).

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com