A kind of unstretched micro-foamed polypropylene film

A polypropylene film and micro-foaming technology, which is applied in the field of packaging plastic film, can solve the problems of film transparency, tear strength, poor heat-sealing performance, heat-sealing wrinkling, etc., and achieve excellent heat-sealing performance, heat-sealing The effect of strong performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

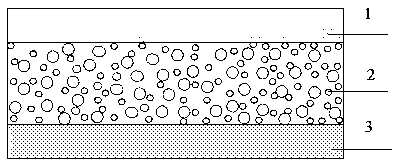

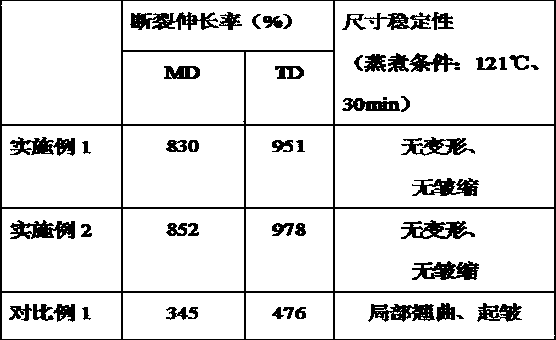

[0017] Such as figure 1 As shown, for the unstretched micro-foamed polypropylene film, the corona layer 1 raw material is 100wt% random copolymer polypropylene with a thickness of 16 μm; the micro-foamed layer 2 raw material is 70wt% isotactic homopolypropylene , a blend of 10wt% polyolefin elastomer and 20wt% foaming masterbatch, with a thickness of 48 μm; the raw material of heat-sealing layer 3 is a blend of 97wt% binary copolymerized polypropylene and 3wt% anti-sticking agent, with a thickness of 16 μm . The three layers of raw materials are melted and extruded by three extruders respectively, extruded through a T-shaped die distributor to a casting chill roll, cast into a sheet, and then subjected to thickness control, corona treatment, winding, aging treatment, Slitting process to finally obtain the finished unstretched micro-foamed polypropylene film, the total thickness of the film is 80 μm; the foam masterbatch is made of the following components in parts by weight: ...

Embodiment 2

[0019] Such as figure 1 As shown, the unstretched micro-foamed polypropylene film, the raw material of the corona layer 1 is 100wt% isotactic homopolypropylene, and the thickness is 15 μm; the raw material of the micro-foamed layer 2 is 67wt% isotactic homopolypropylene. A blend of propylene, 10wt% polyolefin elastomer and 23wt% foaming masterbatch, with a thickness of 70 μm; the raw material of the heat-sealing layer 3 is a blend of 95wt% binary copolymerized polypropylene and 3wt% anti-sticking agent, with a thickness of 15 μm. The three layers of raw materials are melted and extruded by three extruders respectively, extruded through a T-shaped die distributor to a casting chill roll, cast into a sheet, and then subjected to thickness control, corona treatment, winding, aging treatment, Slitting process to finally obtain the finished unstretched micro-foamed polypropylene film with a total film thickness of 100 μm; the foam masterbatch is made of the following components in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com