Anti-pilling odor-resistant woolen sweater

A cashmere sweater and anti-pilling technology, which is applied in biochemical fiber treatment, textiles and papermaking, fiber treatment, etc., can solve the problems affecting the appearance quality and service life of cashmere sweaters, poor fiber cohesion, and poor strength, and achieve anti-pilling Good ball effect, less energy consumption, soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

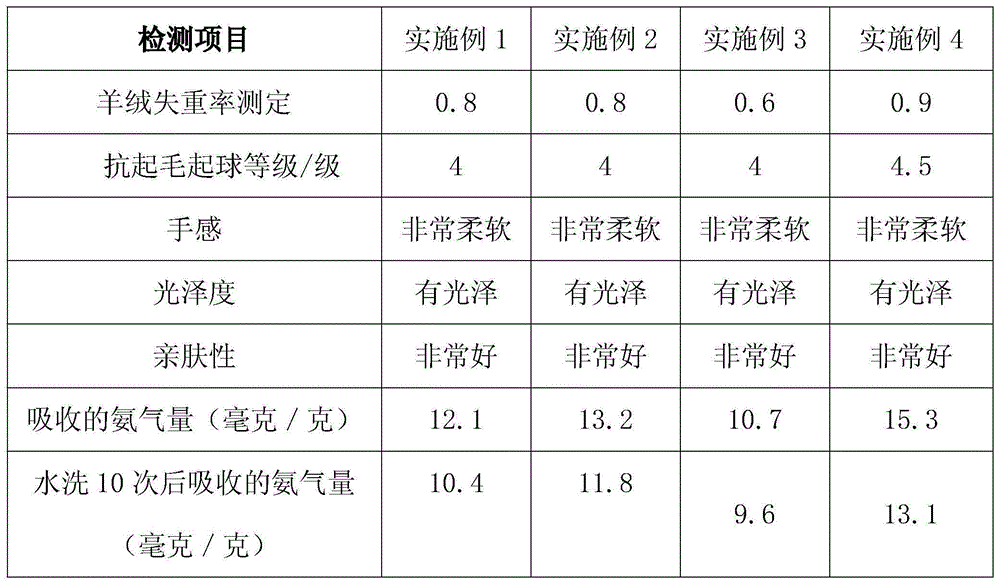

Examples

Embodiment 1

[0025] The processing method of anti-pilling and deodorant cashmere sweater, its steps are as follows:

[0026] (1) select cashmere fiber and milk protein fiber blending, described cashmere and milk protein fiber blending according to mass ratio 4:1;

[0027] (2) Twisting and weaving into garments;

[0028] (3) Anti-pilling and deodorant treatment:

[0029] a. Preprocessing:

[0030] Enzyme pretreatment parameters: polyphenol oxidase 1.1% (owf), laccase 0.8g% (owf), neutral protease 0.6% (owf); bromelain 0.2g% (owf); sodium lactate 0.2% (owf); time 22min, temperature 38℃;

[0031] The enzyme activity of the polyphenol oxidase is 350u / g, the enzyme activity of laccase is 800u / g, the enzyme activity of neutral protease is 500u / g; the enzyme activity of bromelain is 500u / g;

[0032] b. β-cyclodextrin deodorant finishing:

[0033] Dry the pretreated wool blended fabric at low temperature, and then perform deodorant finishing with β-cyclodextrin;

[0034] The processing param...

Embodiment 2

[0040] The processing method of anti-pilling and deodorant cashmere sweater, its steps are as follows:

[0041] (1) select cashmere fiber and milk protein fiber blending, described cashmere and milk protein fiber blending according to mass ratio 4:1;

[0042] (2) Twisting and weaving into garments;

[0043] (3) Anti-pilling and deodorant treatment:

[0044] a. Preprocessing:

[0045] Enzyme pretreatment parameters: polyphenol oxidase 1.5% (owf), laccase 0.5g% (owf), neutral protease 0.7% (owf); bromelain 0.2g% (owf); sodium lactate 0.2% (owf); time 18min, temperature 39℃;

[0046] The enzyme activity of the polyphenol oxidase is 350u / g, the enzyme activity of laccase is 800u / g, the enzyme activity of neutral protease is 500u / g; the enzyme activity of bromelain is 500u / g;

[0047] b. β-cyclodextrin deodorant finishing:

[0048] Dry the pretreated wool blended fabric at low temperature, and then perform deodorant finishing with β-cyclodextrin;

[0049] The processing param...

Embodiment 3

[0055] The processing method of anti-pilling and deodorant cashmere sweater, its steps are as follows:

[0056] (1) select cashmere fiber and milk protein fiber blending, described cashmere and milk protein fiber blending according to mass ratio 4:1;

[0057] (2) Twisting and weaving into garments;

[0058] (3) Anti-pilling and deodorant treatment:

[0059] a. Preprocessing:

[0060] Enzyme pretreatment parameters: polyphenol oxidase 1.2% (owf), laccase 0.7g% (owf), neutral protease 0.6% (owf); bromelain 0.2g% (owf); sodium lactate 0.2% (owf); time 21min, temperature 38℃;

[0061] The enzyme activity of the polyphenol oxidase is 350u / g, the enzyme activity of laccase is 800u / g, the enzyme activity of neutral protease is 500u / g; the enzyme activity of bromelain is 500u / g;

[0062] b. β-cyclodextrin deodorant finishing:

[0063] Dry the pretreated wool blended fabric at low temperature, and then perform deodorant finishing with β-cyclodextrin;

[0064] The processing param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com