Method for treating and recycling coal tar processing wastewater

A technology for processing waste water and coal tar, applied in flotation water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of dilute waste water increasing the processing load of biochemical stations, large economic burden, violation of cleanliness Production and other problems, to achieve the effect of solving the difficulty of effluent compliance, improving biochemical properties, and strengthening biochemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

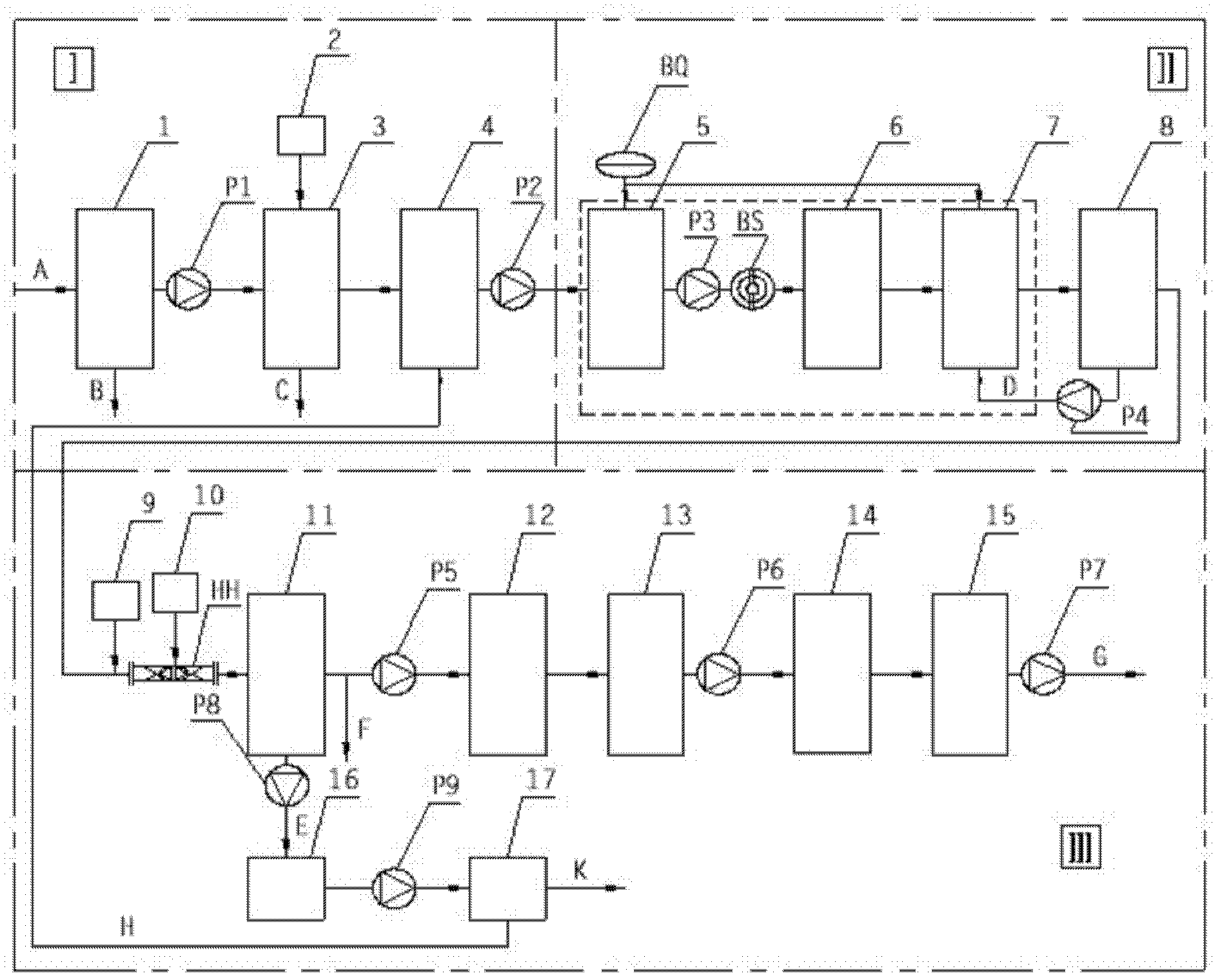

[0021] See figure 1 , is a schematic diagram of the process flow of the method for treating and reusing coal tar processing wastewater of the present invention. This is a combined process method comprising pretreatment, biological treatment and post-treatment, and its process flow is as follows:

[0022] 1) In the pretreatment part I, the processing equipment includes a grease trap 1, an air flotation tank 3 and a hydrolysis acidification adjustment tank 4 connected in sequence. The coal tar processing wastewater A enters the grease trap 1 through the pipe network, and the heavy oil B at the bottom of the pool is collected and then discharged. Transport, the effluent from the grease trap 1 is sent to the air flotation tank 3 through the waste water lifting pump P1, and the air flotation scum C is collected and transported outside. Hydrolysis and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com