Treatment recycle method of sewage from oil refinery

A technology for oil refineries and sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect is not obvious and other problems, to achieve the effect of shortening the sewage reuse process, economical and reasonable sewage reuse, and reducing the amount of difficult-to-treat sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The conditions of the refinery unit and various sewage are the same as those of Comparative Example 1.

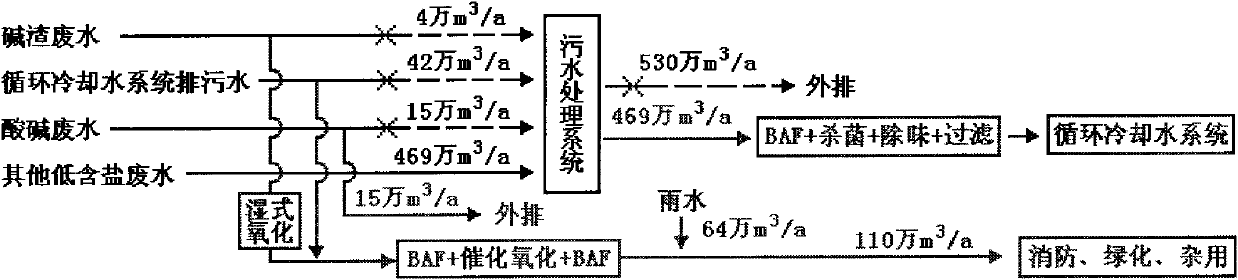

[0034] Such asfigure 1 As shown, the wet oxidation treated 40,000 m 3 / a Alkali slag wastewater and 420,000 m3 of salt containing 1100mg / L 3 / a The sewage from the circulating cooling water system is cut out from the existing sewage treatment system and mixed. The COD after mixing is 1800mg / L. The "BAF+advanced oxidation+BAF" process is used for treatment to obtain sewage with COD3 / a. The rainwater in the factory area with a salt content of 25mg / L is blended, and the obtained mixed water contains a salt content of 900mg / L. The water quality meets the requirements of fire-fighting water and greening water, and all of it can be reused for fire-fighting and greening.

[0035] 4.69 million m3 with a salt content less than 500mg / L 3 / a After the sewage is treated by the sewage treatment system in Comparative Example 1, it is treated with the BAF process. The salt conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com