Preparation method of ZSM-5 molecular sieve nanosphere with multi-level pore hollow structure

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of harsh treatment conditions, long lye treatment time, small mesopore diameter, etc. , to achieve the effect of simple and quick preparation, saving reaction time and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

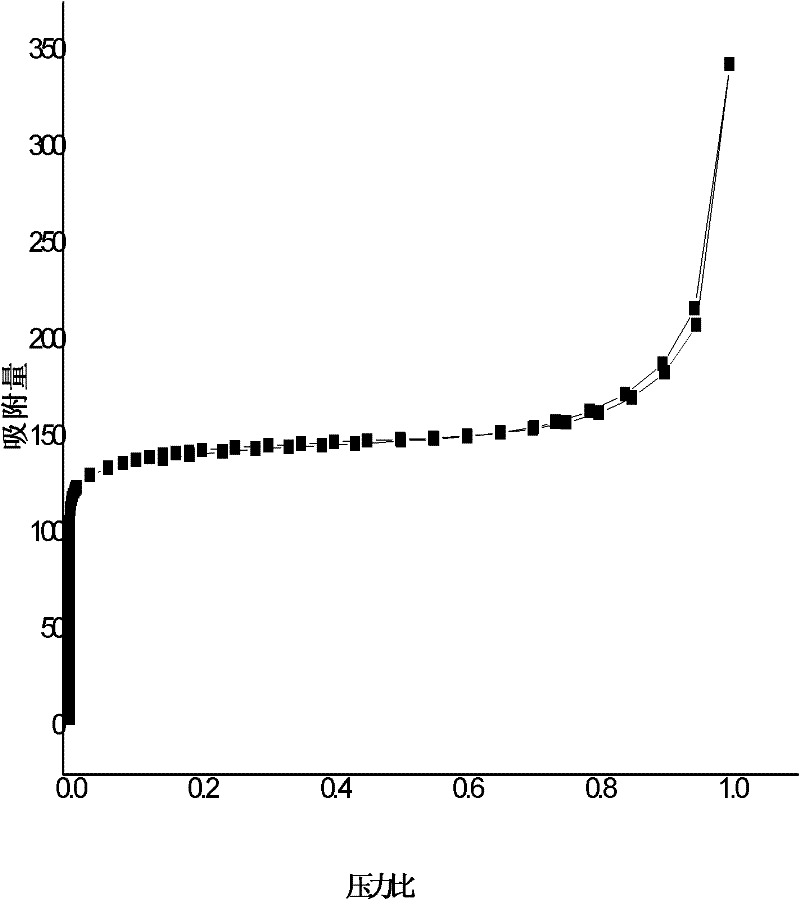

[0024] Synthesis of nano-ZSM-5: add 100g15.7% TPAOH aqueous solution to 32g deionized water, then add 2.24g NaOH (1mol / L), stir for 10min, add 0.54g aluminum isopropoxide, continue stirring for 5h until the solution is clear, then add 64mlTEOS, stirred for 12h until the solution was clear. Put the above solution into a stainless steel reaction kettle lined with polytetrafluoroethylene, crystallize at 100°C for 12h, then transfer to 180°C for 12h to continue crystallization. After the reaction solution is cooled, centrifuge at 8000rpm for 10min, pour off the supernatant, add deionized water, and then ultrasonicate for 10min to disperse the solids in the lower layer evenly into the water, then centrifuge again. After repeating twice, disperse the solids in the lower layer with ethanol. After centrifugation for 10 min, the white solid in the lower layer was dried at 100° C. for 2 h. Calcined at 550°C for 6h to remove the template agent. A nano ZSM-5 molecular sieve with an aver...

Embodiment 2

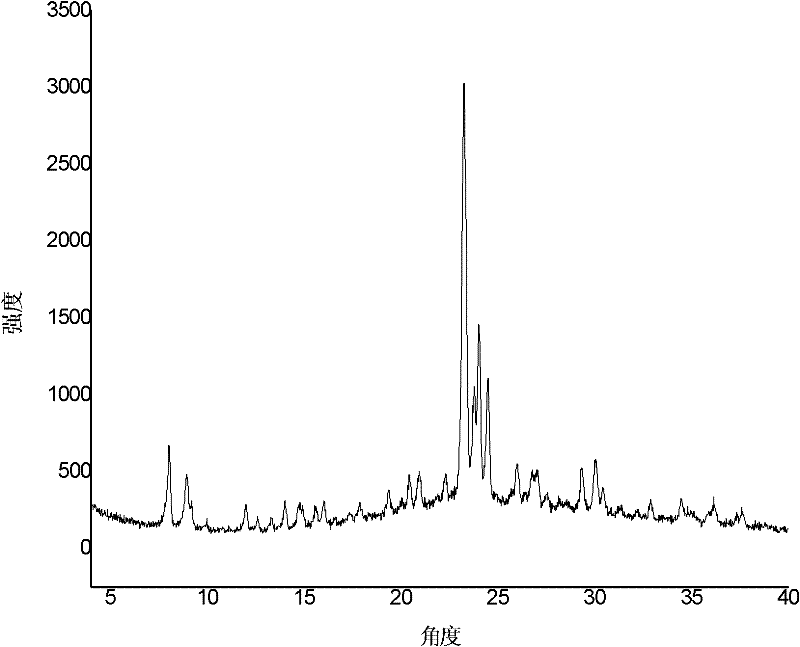

[0027] The experimental method is the same as in Example 1, and the microwave treatment time is changed to 15s. The result obtained is a hierarchically porous ZSM-5 molecular sieve nanosphere with meso-micropores, and the average size of the hollow pores is about 50nm. Figure 5 It is a spectrum obtained by X-ray diffraction. It can be seen from the figure that the sample still shows a high crystallinity ZSM-5 molecular sieve after microwave treatment. Figure 6 The scanning electron microscope photos of the sample are given, and the average size of the pores in the ZSM-5 grains decreases, and the average size of the hollow pores is about 50nm. The results show that the hollow nano ZSM-5 molecular sieves can still be prepared by shortening the microwave treatment time, but the pore size of the hollow pores decreases.

Embodiment 3

[0029] The experimental method was the same as in Example 1, but the microwave treatment time was changed to 18s, and the obtained result was macropore-micropore hierarchically porous ZSM-5 molecular sieve nanospheres, and the average size of the hollow pores was about 80nm. The spectrogram that X-ray diffraction obtains shows that sample is the ZSM-5 molecular sieve of high crystallinity ( Figure 7 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com