Controllable mix abrasive jet polishing equipment for large-scale ultra-precision optical glass

An optical glass and abrasive jet technology, which is applied in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve problems such as low cost requirements, inability to meet large glass processing, etc., and achieve the effect of improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

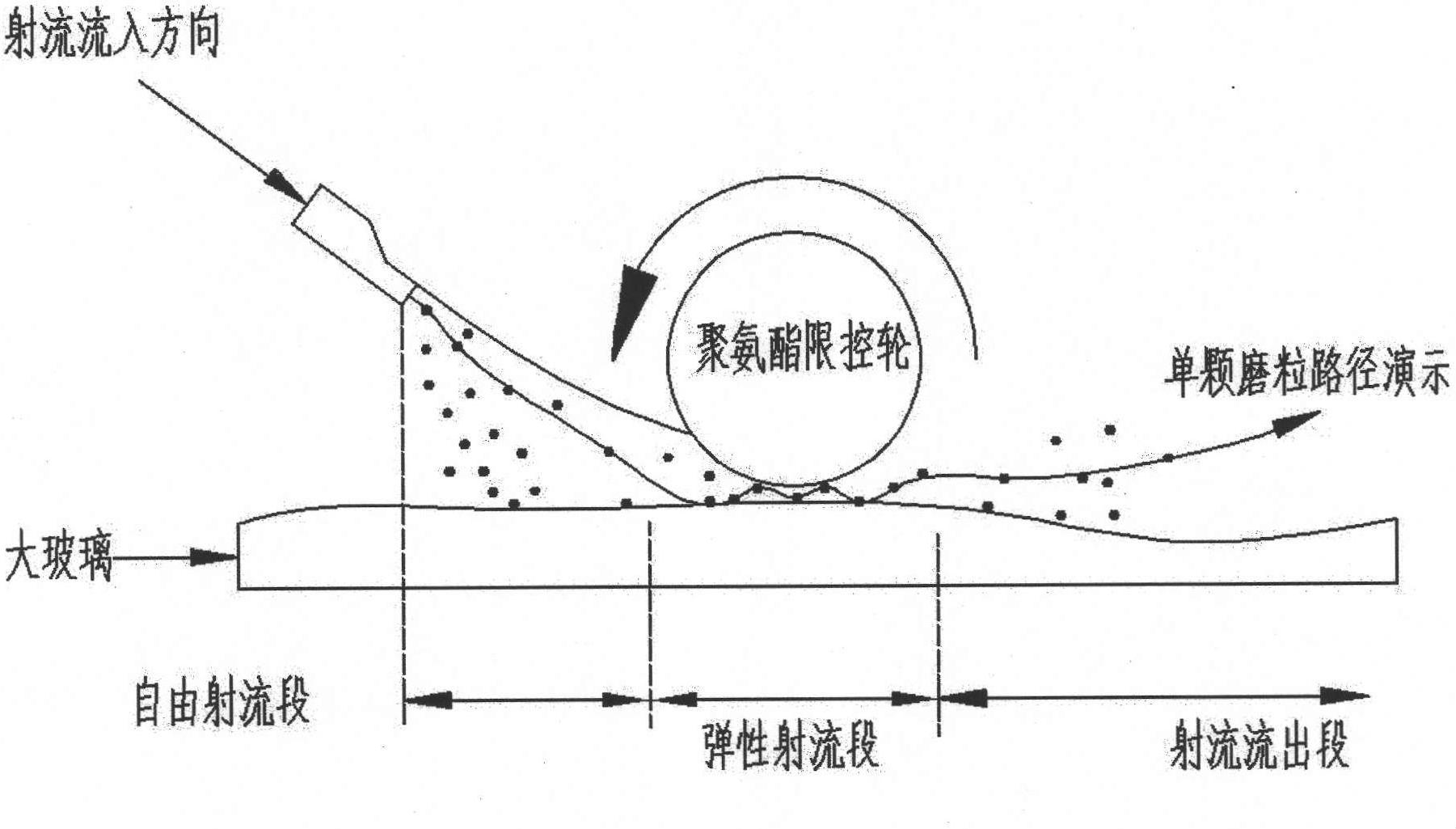

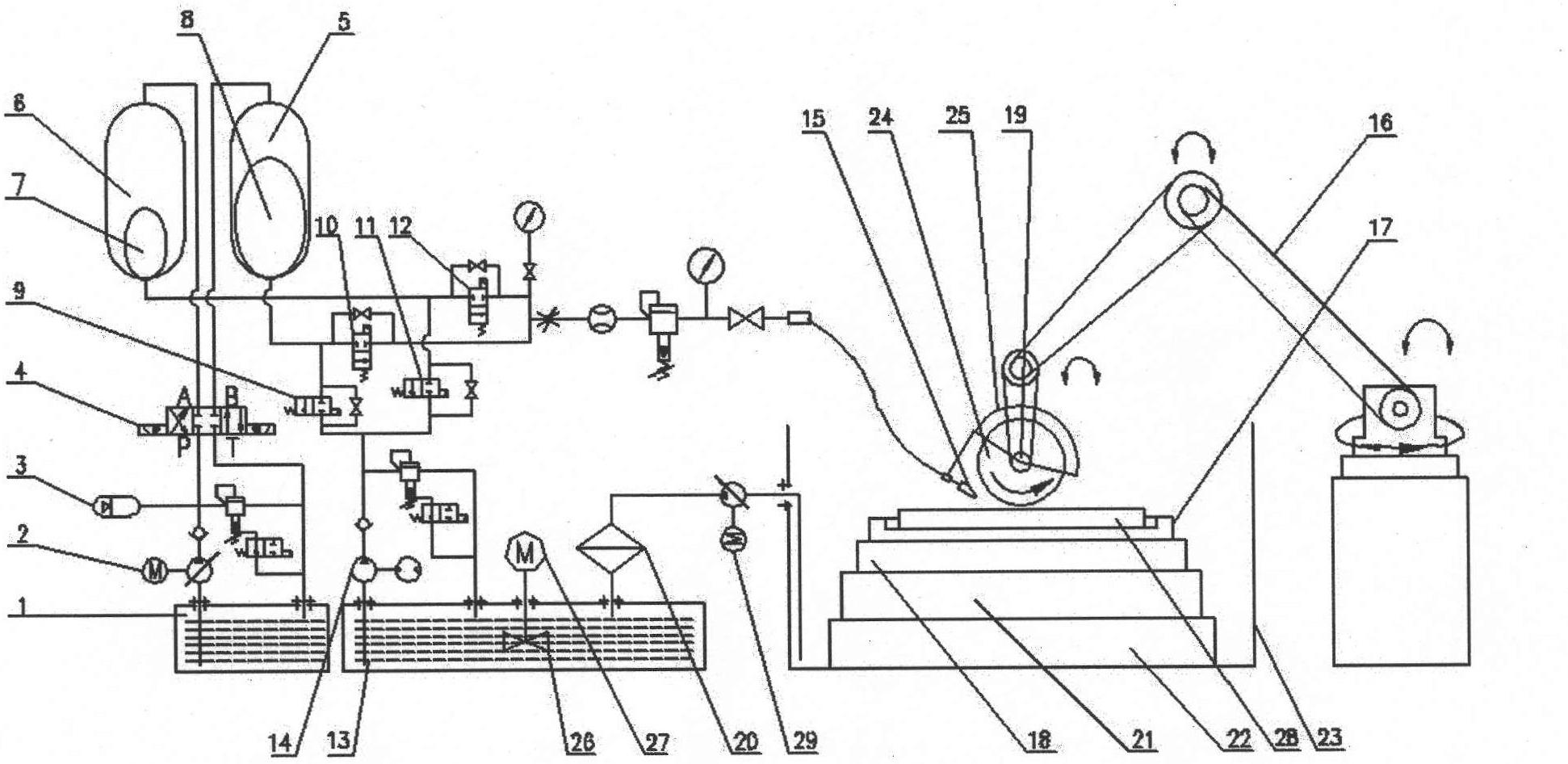

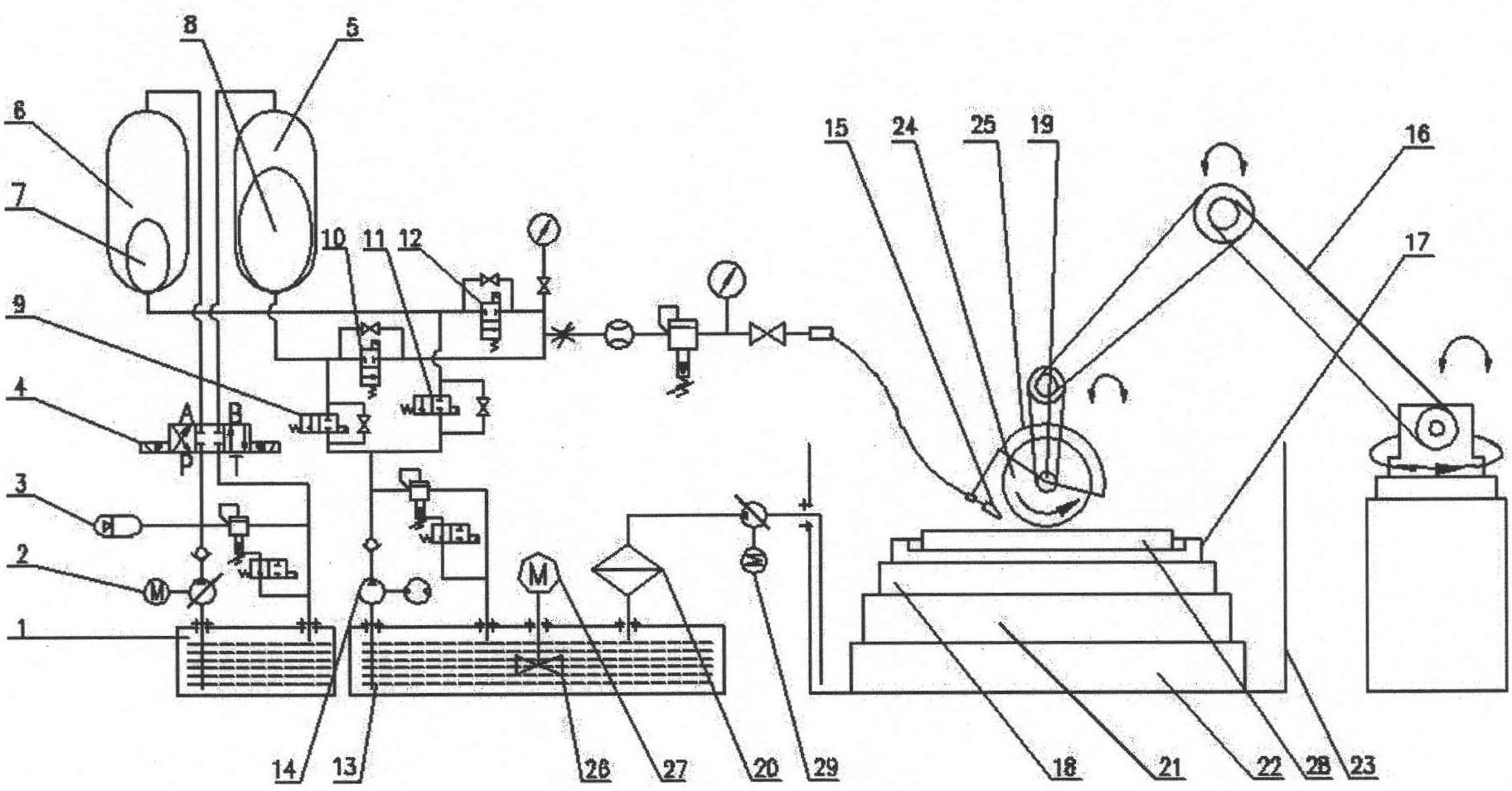

[0016] Such as figure 2 As shown, it is a schematic diagram of a large-scale ultra-precision optical glass controllable mixed abrasive jet polishing equipment. The large-scale ultra-precision optical glass controllable mixed abrasive jet polishing equipment includes a jet generation and transmission system and a robot controllable abrasive fluid polishing system.

[0017] The jet generation and transmission system includes a hydraulic oil tank 1 fixed on a flat ground, the hydraulic oil tank 1 is connected to the suction port of the first diaphragm pump 2, and the outlet of the first diaphragm pump 2 is connected to the three-position four-way solenoid valve 4 The P end, the A end and the B end of the three-position four-way solenoid valve 4 are respectively connected to the second high-pressure container 6 and the first high-pressure container 5, and the second high-pressure container 6 is provided with a first flexible sealing bladder 7, and the first high-pressure containe...

Embodiment 2

[0026] Such as figure 2 As shown, it is a schematic diagram of a large-scale ultra-precision optical glass controllable mixed abrasive jet polishing equipment, and the large-scale ultra-precision optical glass controllable mixed abrasive jet polishing equipment is the same as that in Example 1.

[0027] When using the above-mentioned equipment to perform inching polishing on the separation high point of the large glass surface, open the first two-position two-way reversing valve 9, close the second two-position two-way reversing valve 10, and the third two-position two-way reversing valve Valve 11 and the fourth two-position two-way reversing valve 12 start the second diaphragm pump 14, and deliver the mixed abrasive polishing liquid to the second flexible sealing bladder 8 in the first high-pressure container 5, and the mixed abrasive polishing liquid is filled with the second When the flexible sealing bladder 8 is used, the first two-position two-way reversing valve 9 is cl...

Embodiment 3

[0029] Such as figure 2 As shown, it is a schematic diagram of a large-scale ultra-precision optical glass controllable mixed abrasive jet polishing equipment, and the large-scale ultra-precision optical glass controllable mixed abrasive jet polishing equipment is the same as that in Example 1.

[0030] When the above-mentioned equipment is used to polish the large glass surface as a whole, it is similar to the continuous polishing of the large glass surface according to the set path. The difference is that the first axial guide rail 22 and the second axial guide rail 21 are fixed, and the turntable 18 keeps rotating. The six-degree-of-freedom robot 16 drives the electric spindle 19 and the polyurethane control wheel 24 to move back and forth at a constant speed along the radial direction of the large glass surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com