Method for calibrating openness of vertical roll of rolling mill

A calibration method and technology of opening degree, which is applied in the direction of metal rolling, metal rolling, length measuring device, etc., can solve the problems of inaccurate calibration of vertical roll opening degree, no safety guardrail, affecting the accuracy of slab width control, etc. , to achieve the effect of saving measurement and maintenance time, avoiding personal injury accidents, improving work efficiency and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Take the 1580mm rolling mill as an example below to further illustrate the present invention.

[0027] First, on the vertical roller control screen, open the vertical roller opening to 1200mm.

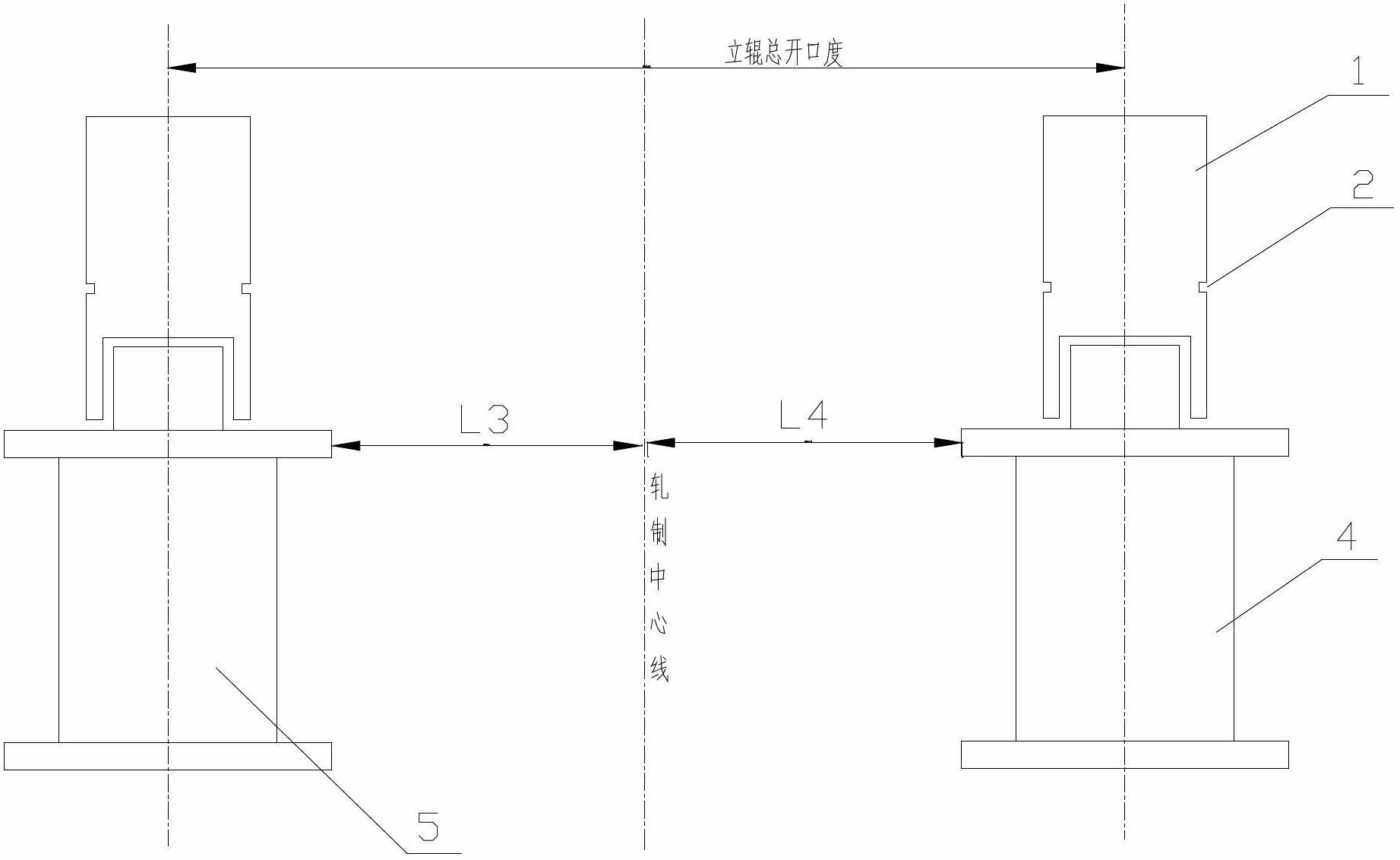

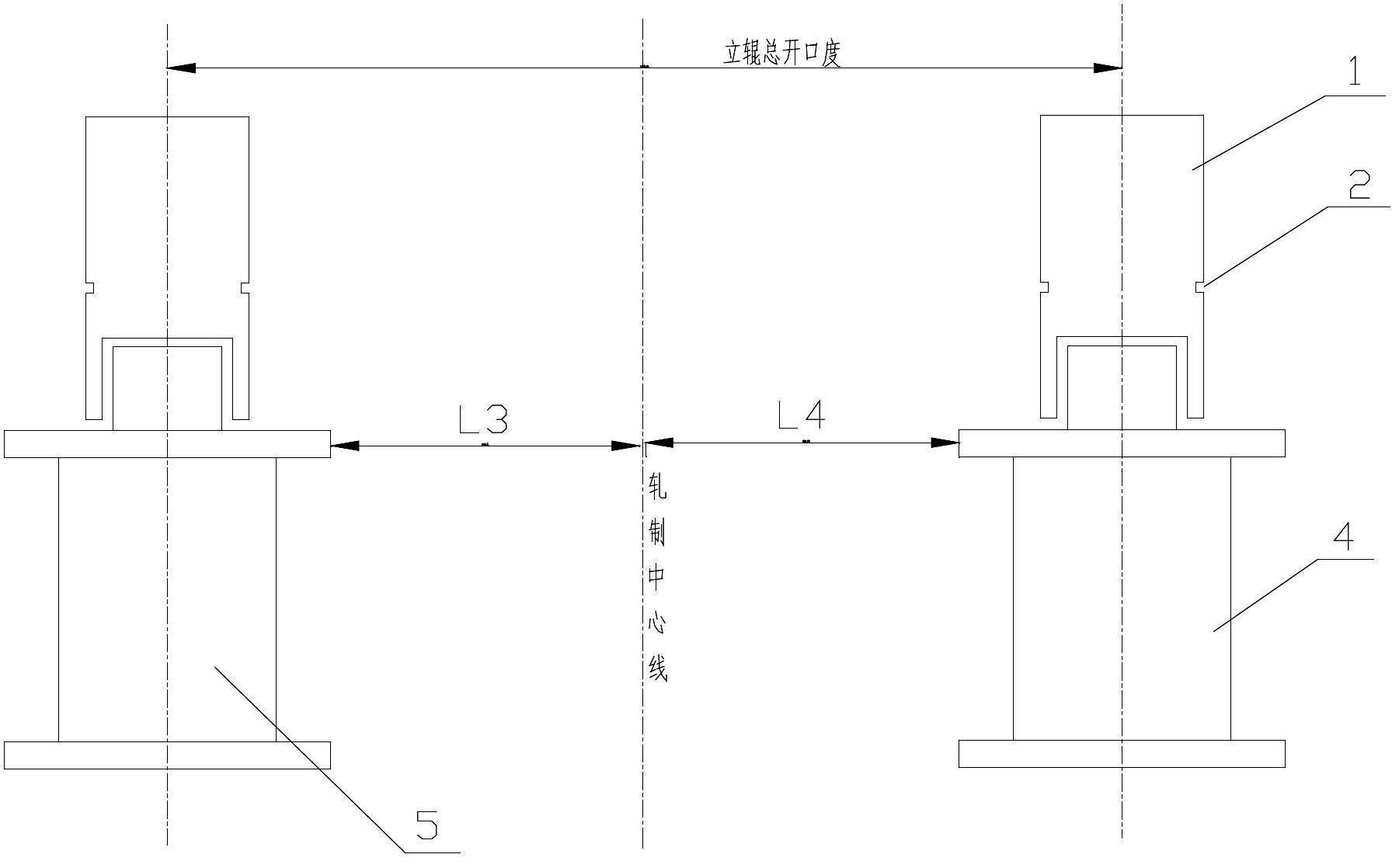

[0028] The surveyor stands next to the vertical roller, wraps a thin wire 3 around the vertical roller flat head ring 2 of the two vertical roller flat head covers 1, and then measures the length L wrapped by the thin wire 3 1 =2800 mm.

[0029] Wrap a single vertical roller flat head collar 2 with a thin wire, then measure the length L wound by the thin wire 2 =500 mm.

[0030] Then, measure the distance L between the rolling center line and the edge of the left vertical roller 5 bearing box with a board ruler 3 =800 mm; then measure the distance L between the rolling center line and the edge of the right vertical roll 4 bearing box 4 =798 mm.

[0031] Calculate the total opening of the vertical roller, that is, the distance between the centers of the two vertical rollers:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com