Silver rare earth oxide contact material for low-voltage switching device and preparation method thereof

A rare earth oxide, low-voltage switch technology, applied in the direction of electric switches, contacts, circuits, etc., can solve the problem of low electrical life, achieve the effect of improving electrical conductivity, fine particles, and solving the effect of easy fracture after drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

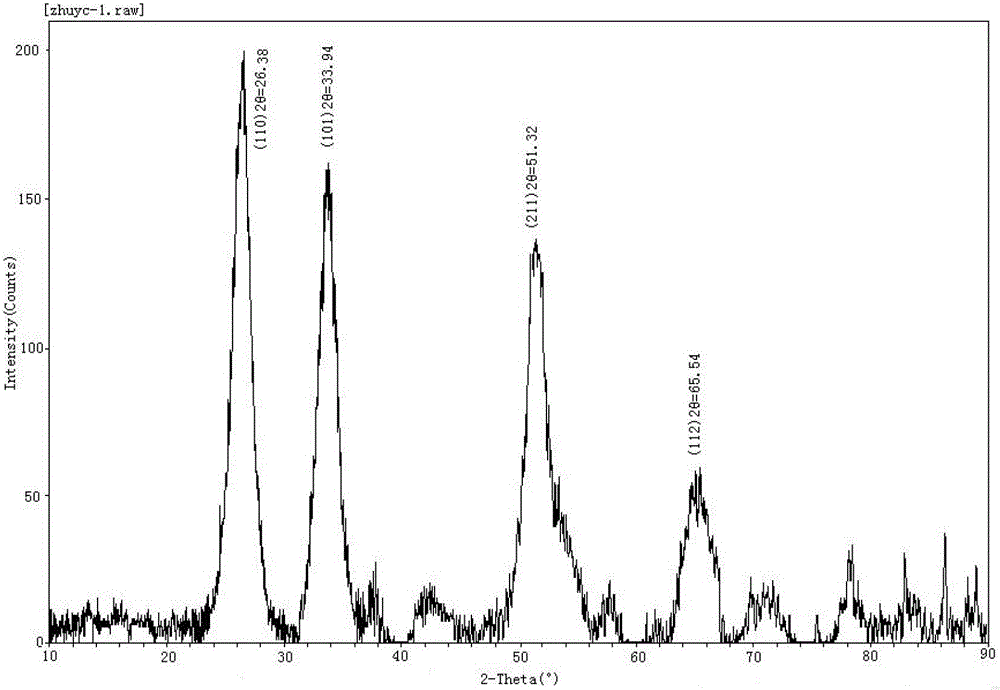

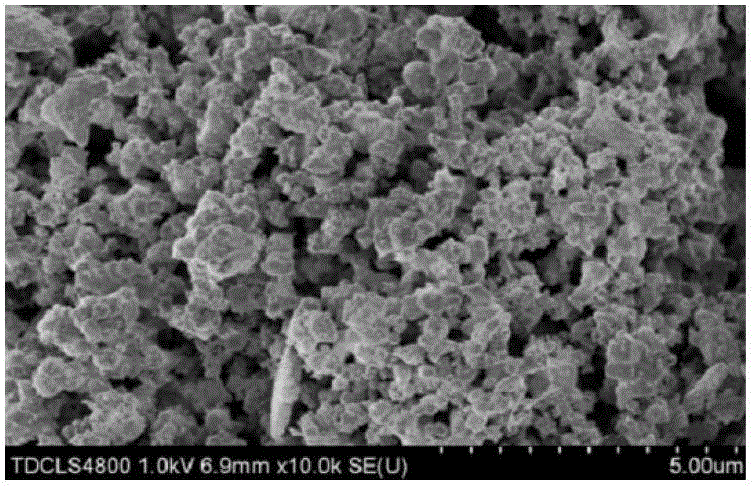

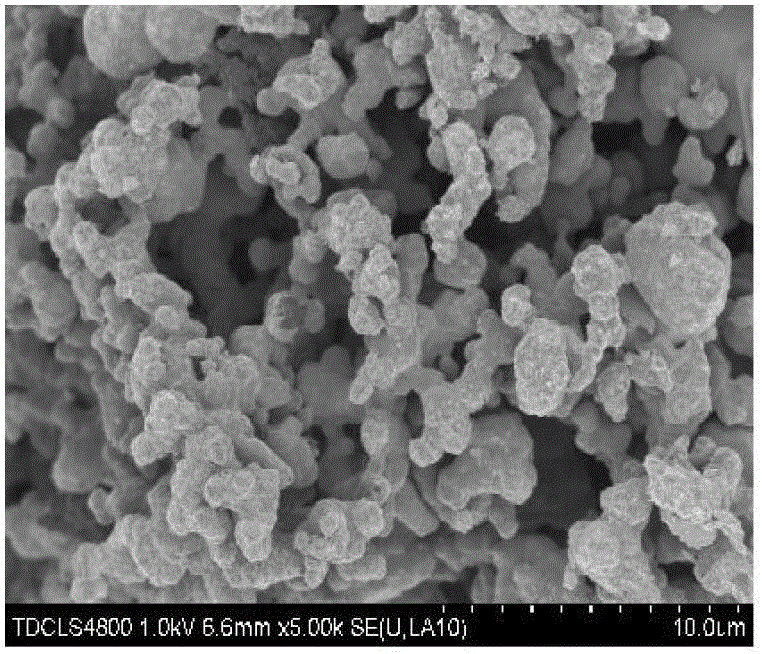

Image

Examples

Embodiment 1

[0030] Prepare an ethanol distilled aqueous solution with a volume ratio of distilled water and ethanol of 1:1 as a solvent, and prepare a sufficient amount of diluted ammonia water with a mass concentration of 10%. Take by weighing tin chloride pentahydrate, lanthanum chloride and titanium chloride powder by mass ratio 90:5:5, it is dissolved in the ethanol distilled aqueous solution above respectively, is formulated into the solution of 0.2mol / L respectively, then three All the solutions were mixed, and placed on a magnetic stirrer platform to stir to make them uniform, and the precursors of tin, lanthanum and titanium were obtained. Add polyethylene glycol (molecular weight 400) with a volume percentage of 2% of the mixed solution dropwise into the solution as a dispersant. After the temperature rose to 65°C, keep stirring for 20 minutes.

[0031] After stirring evenly, add dropwise ammonia water with a mass ratio of 10%-12% until the solution becomes gelatinous (at this tim...

Embodiment 2

[0046] The difference is that ytterbium chloride replaces lanthanum chloride, and tin chloride pentahydrate, ytterbium chloride and titanium chloride powder are weighed in a mass ratio of 94:3:3. The rest is the same.

[0047] Using powder metallurgy process, according to Ag:SnO 2 / Tb 2 o 3 -TiO 2 =85:15 (mass ratio) mixing, cold pressing-sintering-repressing-extrusion-drawing to make silver rare earth oxide contact material.

[0048] Alloy performance indicators:

[0049] Resistivity 2.43μΩ.cm

[0050] Density 9.86 g / cm 3

[0051] Hardness 970 MPa

Embodiment 3

[0053] The difference is that europium chloride replaces lanthanum chloride. Weigh tin chloride pentahydrate, europium chloride and titanium chloride powders in a mass ratio of 90:5:5. The rest is the same.

[0054] Using powder metallurgy process, according to Ag:SnO 2 / Eu 2 o 3 -TiO 2 =90:10 (mass ratio) mixing, cold pressing-sintering-repressing-extrusion-drawing to make silver rare earth oxide contact material.

[0055] Alloy performance indicators:

[0056] Resistivity 2.39μΩ.cm

[0057] Density 9.82 g / cm 3

[0058] Hardness 978 MPa

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com