Multi-stage exchange system and exchange method for multi-station silicon wafer stage

A technology of exchange system and wafer table, applied in multi-station wafer table multi-table exchange system and its workflow field, can solve the problems of increasing work area and production cost, reducing silicon wafer processing efficiency, etc., and achieve cost reduction and the use of area, the effect of improving productivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principle, structure and implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

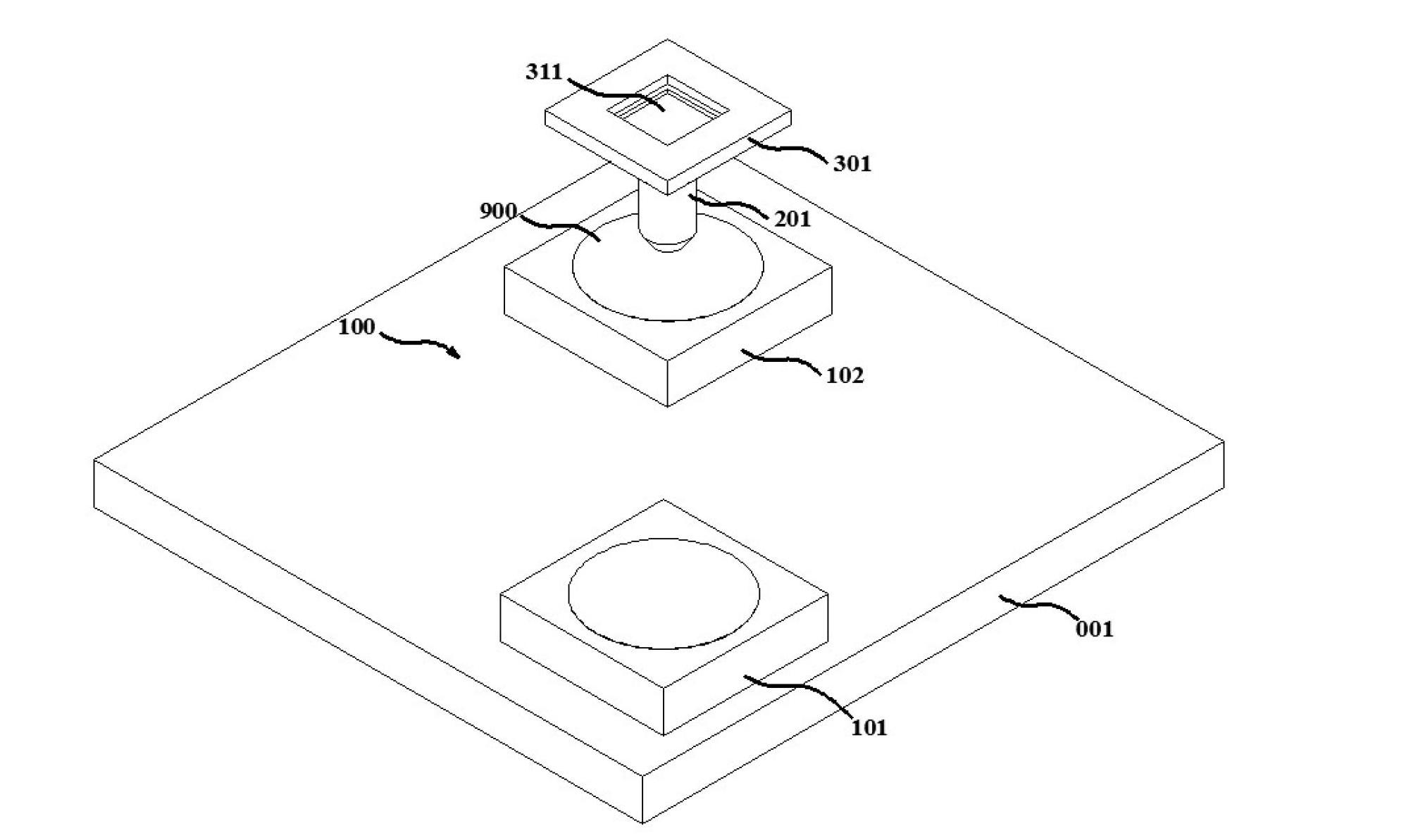

[0028] figure 1 It is a two-station silicon wafer platform dual-station exchange system in the existing dual-station exchange lithography machine, including the base station 001, the measurement station 101, the exposure station 102 and two wafer holders for carrying silicon wafers 900; the base station The upper surface 100 of the stage is an air-floating plane or a magnetic-floating plane, and the measuring station and the exposure station are located on the upper surface of the base; Complete the exchange between the measurement station and the exposure station. The existing two-station silicon wafer exchange system has only two stations, the measurement station and the exposure station, both of which are equipped with measurement and alignment instruments and auxiliary parts. The exposure station is also equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com