Method for rapidly displaying titaniferous inclusions in field condition based on corrosion principle

A technology for field conditions and inclusions, applied in the preparation of test samples, measurement devices, and material analysis by optical means, etc., can solve the problems of resolution and magnification limit, difficult polishing process, and complicated operation, and achieve display Good effect, improved sample preparation efficiency and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present invention is a method for quickly displaying titanium-containing inclusions under field conditions based on the principle of erosion, comprising the following steps:

[0020] (1) Prepare metallographic samples and finely grind them to 2000# sandpaper;

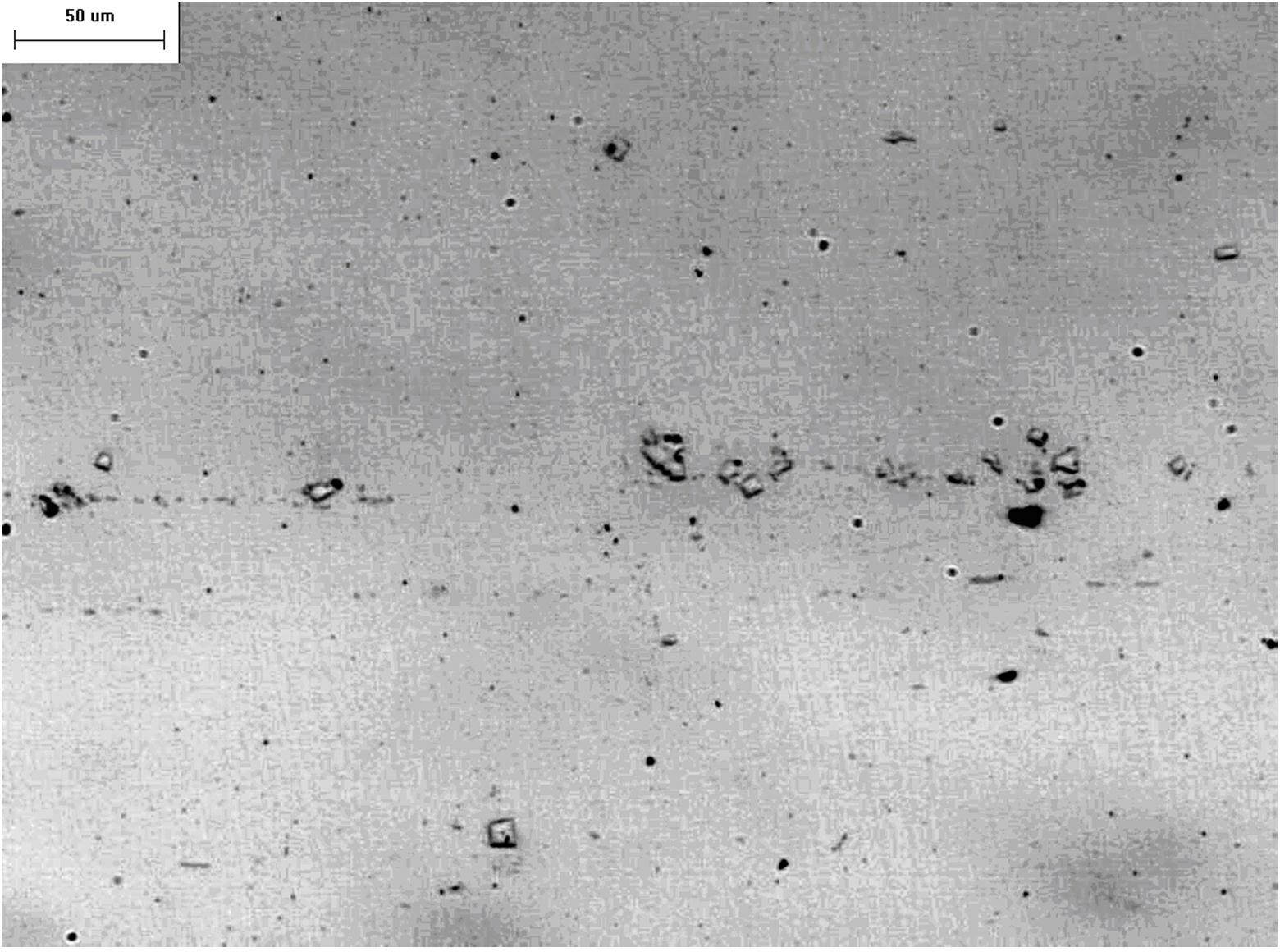

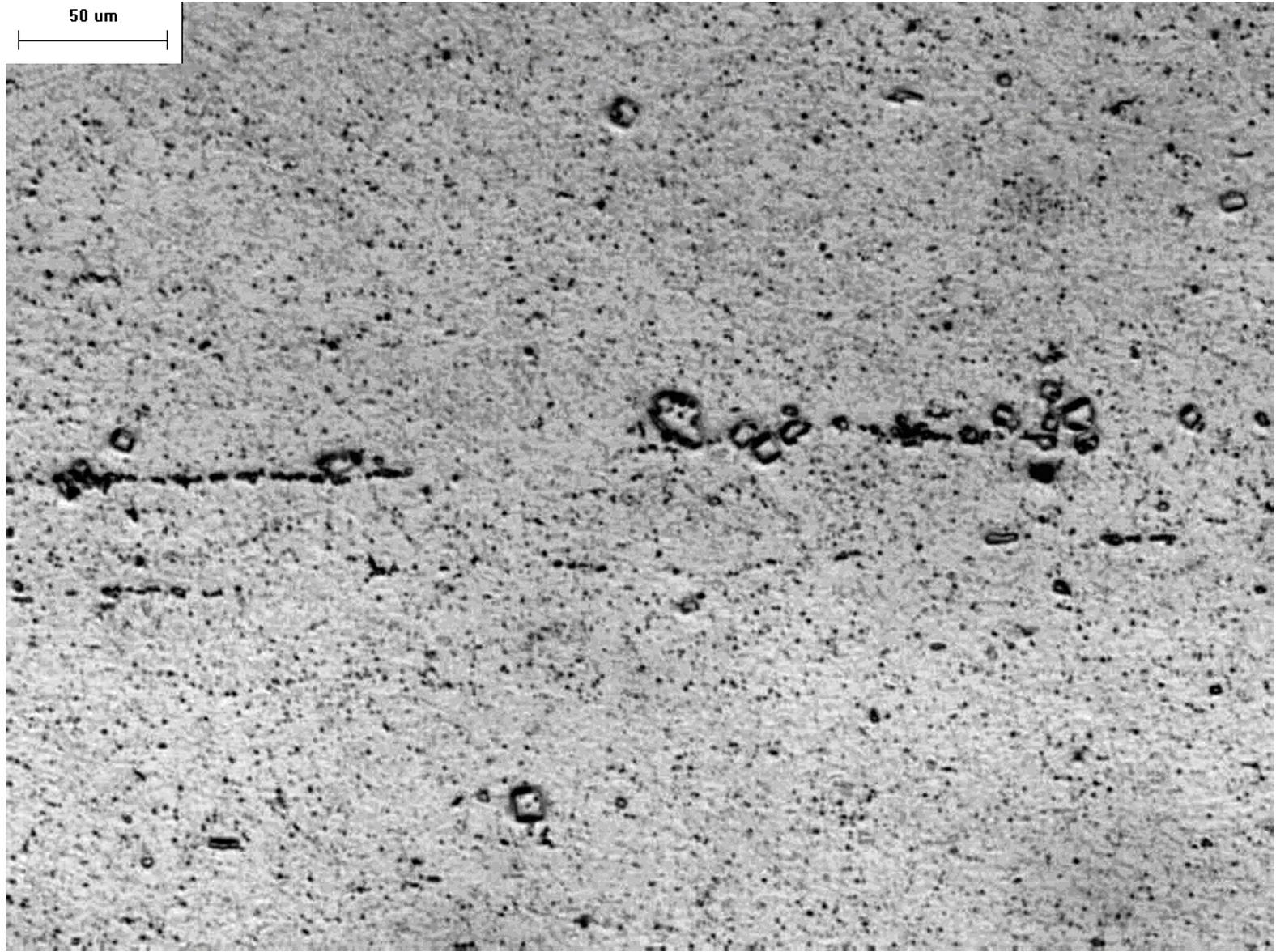

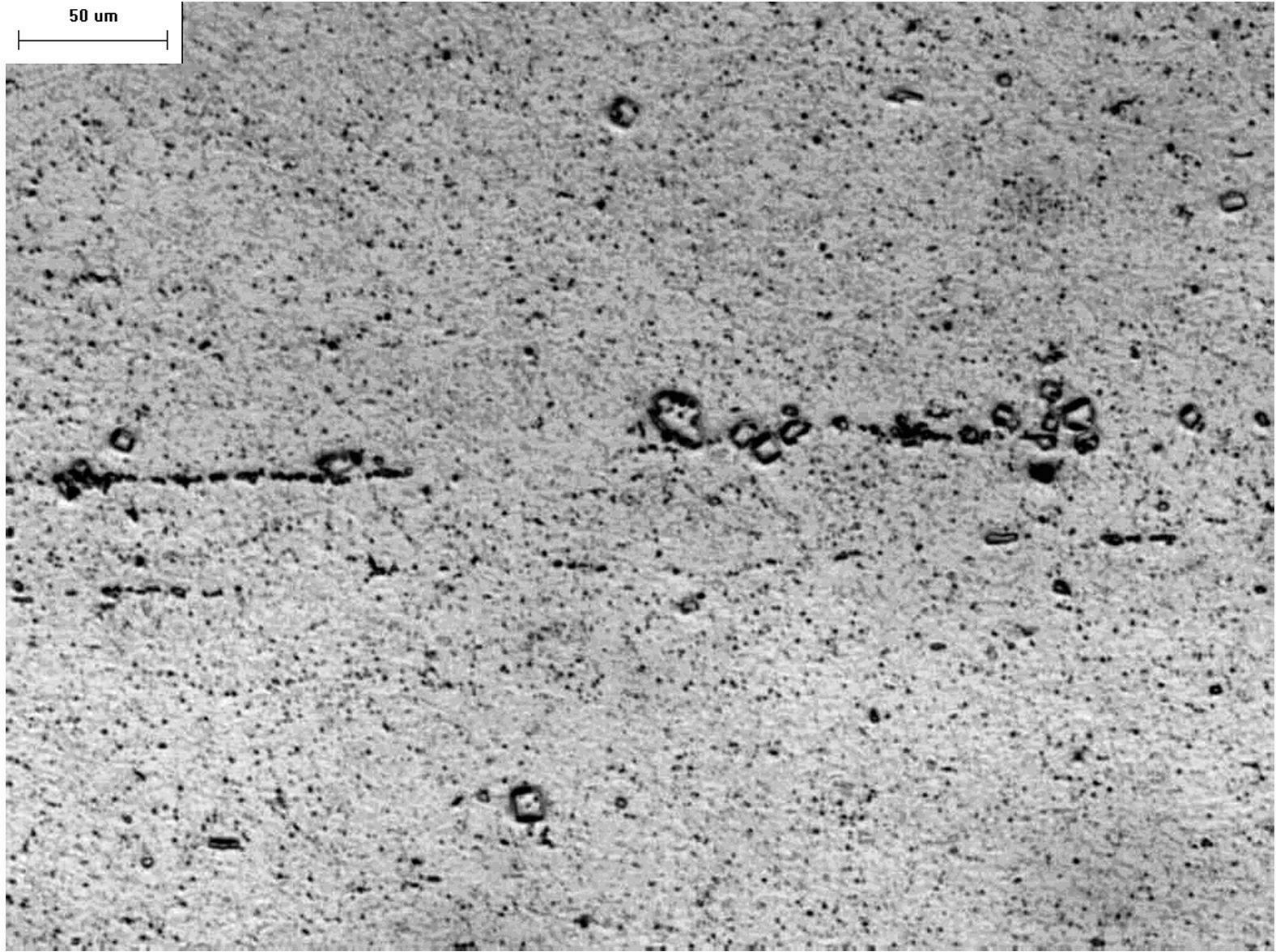

[0021] (2) Use special chemical reagents to erode the surface of the ground sample, which can achieve the effect of polishing and displaying the morphology of titanium-containing inclusions at the same time;

[0022] (3) Use an on-site metallographic microscope to observe or use film coating technology to sample and analyze.

[0023] Fine grinding of the present invention is to use 120#, 240# to carry out coarse grinding successively, and then use 400#, 600#, 1000#, 1500# and 2000# sandpaper to carry out fine grinding.

[0024] The special chemical reagent of the present invention comprises: hydrogen peroxide, hydrofluoric acid, oxalic acid.

Embodiment 2

[0026] 1. Conduct metallographic sample preparation on the surface of the bolt waist to be inspected, use 120#, 240# for rough grinding, and then use 400#, 600#, 1000#, 1500# and 2000# sandpaper for fine grinding;

[0027] 2. Use the special chemical reagent hydrogen peroxide to erode the surface of the ground sample, which can achieve the effect of polishing and displaying inclusions at the same time;

[0028] 3. A portable metallographic microscope can be used for observation on site.

Embodiment 3

[0030] 1. Conduct metallographic sample preparation on the surface of the bolt waist to be inspected, use 120#, 240# for rough grinding, and then use 400#, 600#, 1000#, 1500# and 2000# sandpaper for fine grinding;

[0031] 2. Use special chemical reagent hydrofluoric acid to erode the surface of the ground sample, which can achieve the effect of polishing and displaying inclusions at the same time;

[0032] 3. Sampling and analysis can be carried out on site using film coating technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com