Leakage detecting device

A leak detection and cylinder block technology, which is applied in the direction of measuring the increase and decrease rate of the fluid, and using the liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problems of complicated operation and long operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

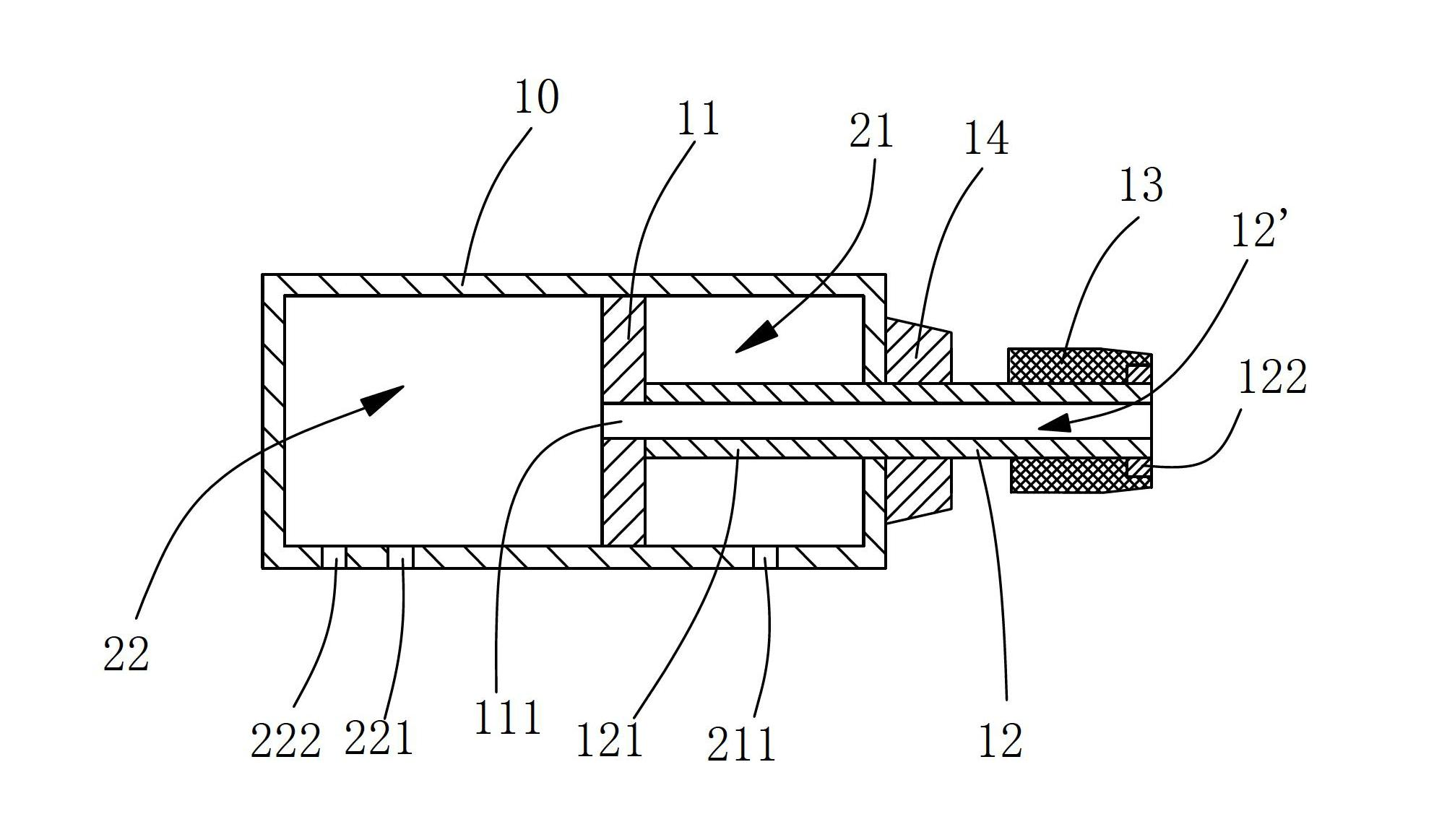

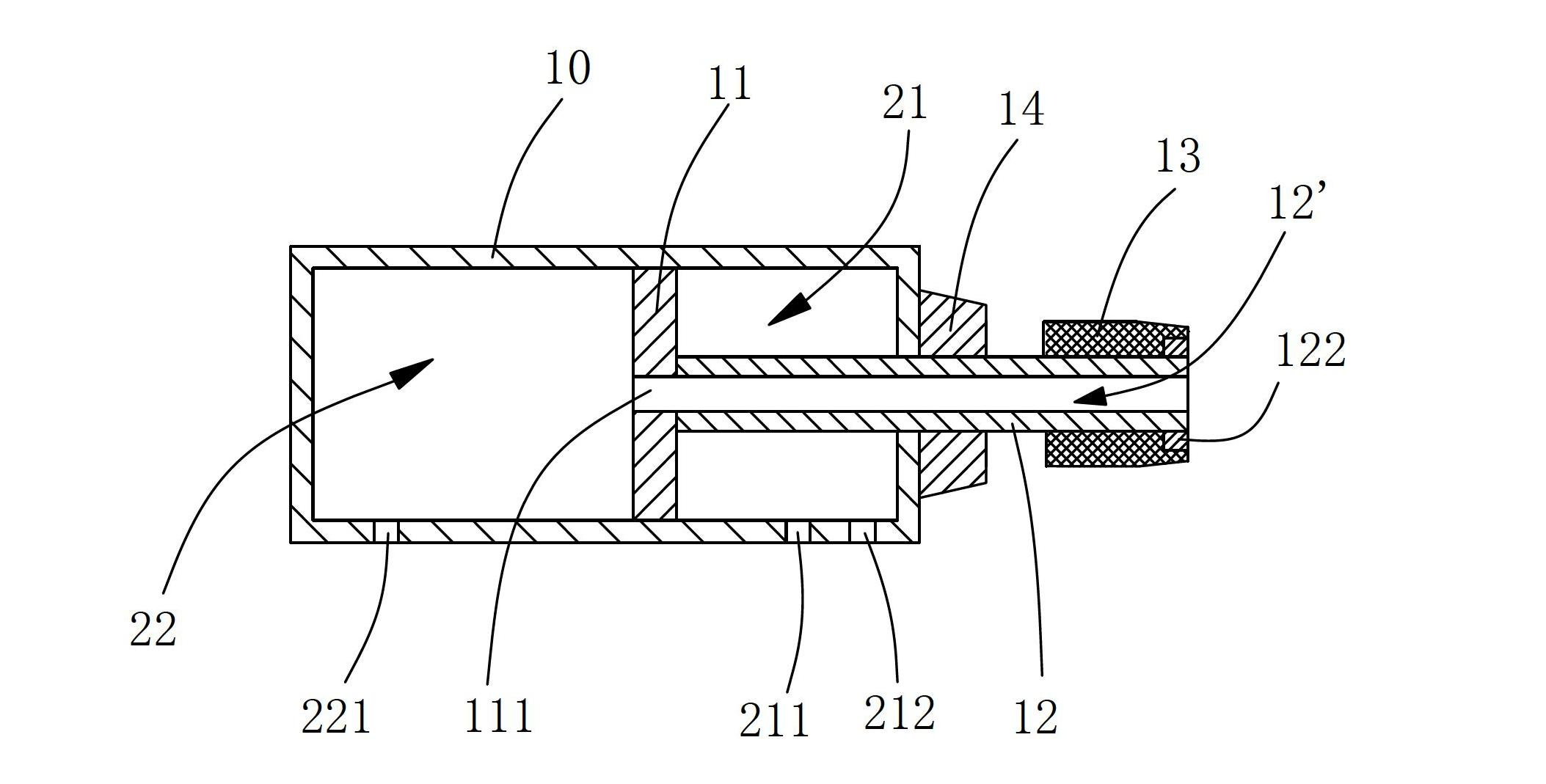

[0011] like figure 1 , 2 Shown is the first embodiment of the present invention, a third through hole 111 is opened at the plate surface where the piston 11 is connected to the piston rod 12, and the inflation channel 12' and the second chamber 22 pass through the third through hole 111. The through holes 111 are connected. The plug 13 is made of elastic material, and the diameter of the plug 13 is slightly smaller than the inner diameter of the connecting pipe 30 . In this embodiment, the plug 13 is put into the connecting pipe 30 in the initial state, and by rushing gas through the first through hole 221, the gas will fill the inside of the first chamber 21, thereby pushing the piston 11 and driving the plug 13 moves to the side close to the cylinder body 10, because a bracket 14 is arranged between the plug 13 and the cylinder body 10, and a through hole for the piston rod 12 is opened in the middle of the bracket 14, and the The outer end surface of the bracket 14 is fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com