Flat-flame nozzle with automatic ignition and flame detection device

A flame detection device and a technology of a flat flame burner are applied in the field of metallurgy, which can solve the problems such as impossibility of pulse control, and achieve the effects of increasing automatic ignition and flame detection functions, ensuring uniformity, and having a large power adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

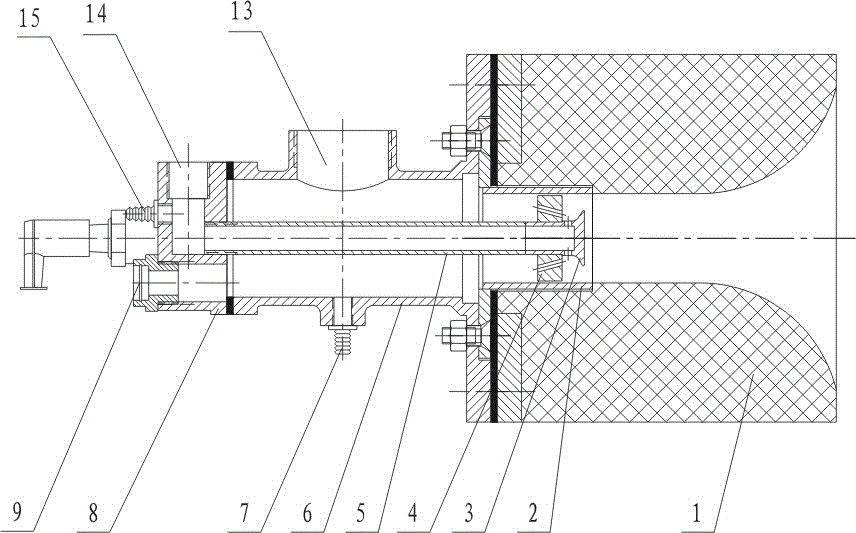

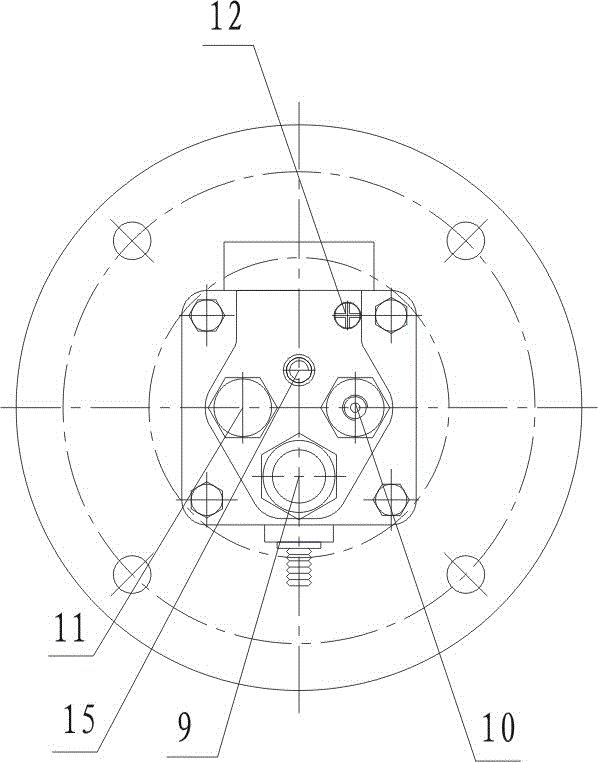

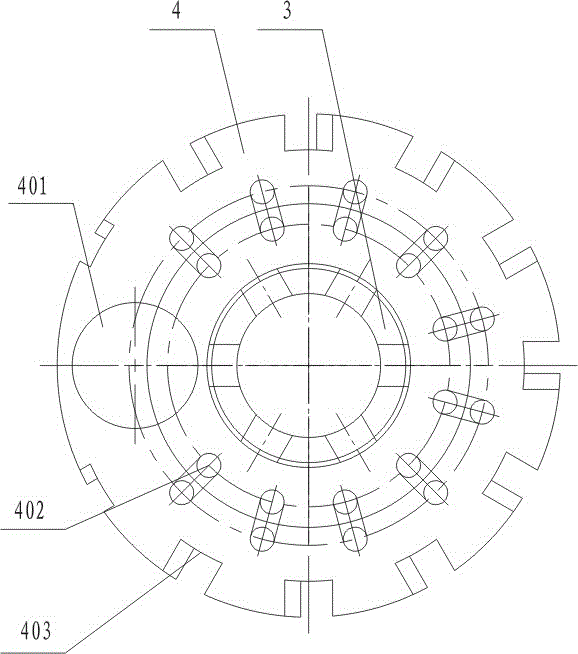

[0017] For a better understanding of the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and accompanying drawings, see Figure 1 to Figure 5 :

[0018] According to the flat flame burner with automatic ignition and flame detection device implemented in the present invention, it mainly includes burner brick 1, air pipe shell 6, gas pipe shell 8, gas core pipe 5, air distribution plate 4, gas nozzle Flame stabilizer 3.

[0019] The burner brick 1 is a cylinder with a horn-shaped spout, placed horizontally. The anchor nails are welded on the fixed plate at the tail, and the burner brick is molded with castable materials. The long-term use temperature is 1350 ° C, and the highest temperature resistance level can reach 1600 ° C. The diameter and length of the inlet and outlet of the burner brick 1 are formed according to the burner power and the flat flame. Calculation and determination of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com