Gas compression and storage system and control method

A storage system and gas compression technology, applied in the field of gas compression, can solve problems such as difficult to ensure stable gas volume, difficult to ensure the safety of gas cabinets, etc., to achieve the effect of convenient communication, avoiding unstable work, and ensuring balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

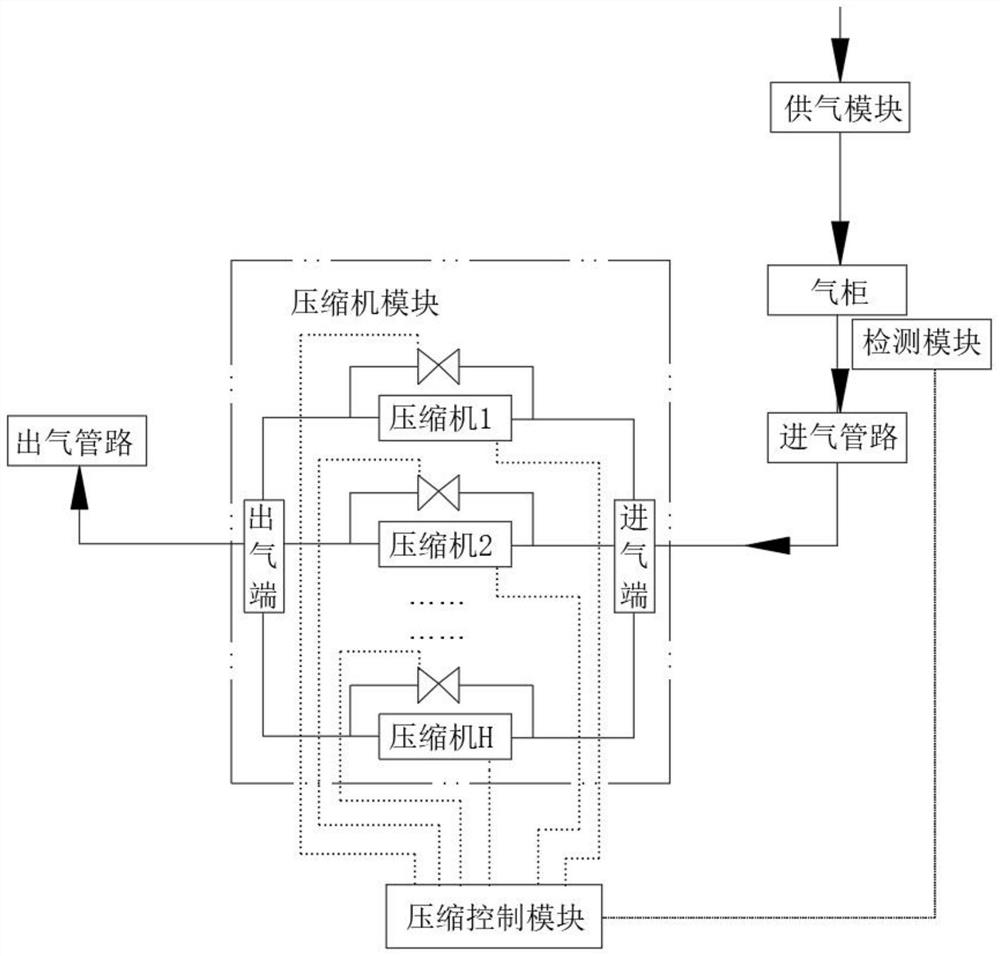

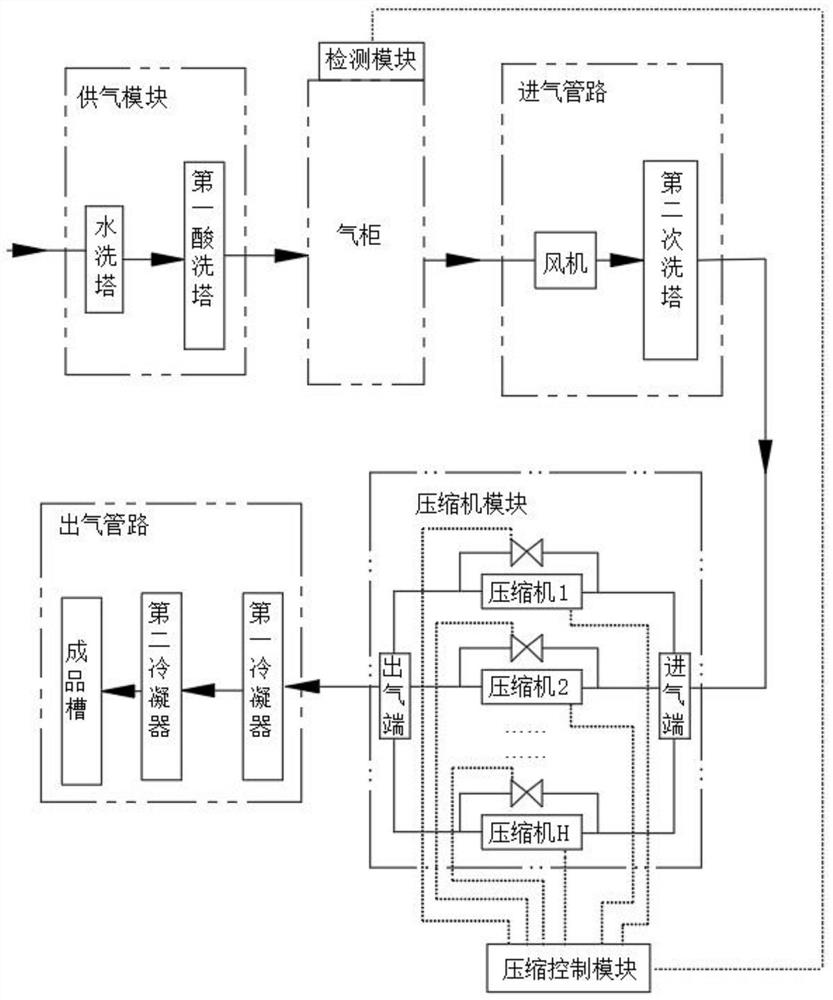

[0037] A gas compressor according to the embodiment proposed memory system, comprising: a supply module, a gas tank, an intake pipe, a compressor module, the outlet conduit, a detection module and a compression module control.

[0038] Compressor module comprising inlet end, outlet end and a plurality of parallel between the inlet end and the outlet end of the compressor. Thus, by controlling the respective operating state of the compressor, the compressor can control the total power module, such that the compressor module needs to adapt to different conditions. Air supply module, the gas cabinet, and the intake line sequentially connecting the inlet end, the outlet end is connected with the outlet conduit. Gas supply module to supply the gas cabinet, a gas through the gas cabinet in the intake line enters the compressor module to compress the compressed gas outlet conduit through the output. In specific implementation, the intake line may include various devices for gas processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com