Continuous filament wound and reinforced thermoplastic pipe and manufacturing process thereof

A technology of winding enhancement and manufacturing process, applied in rigid pipes, pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor process performance, pollution, low strength and elastic modulus, and achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

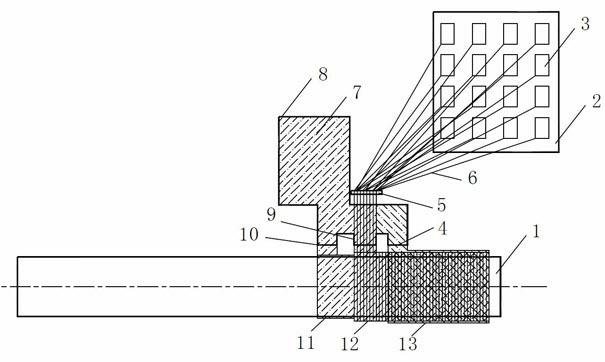

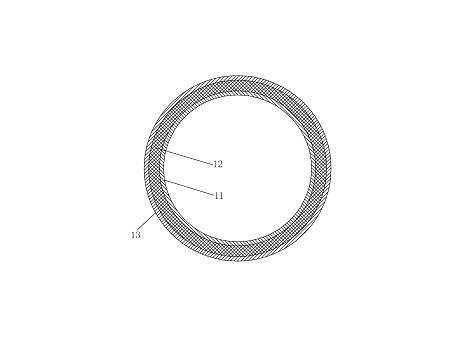

[0025] A continuous long fiber winding reinforced thermoplastic pipe, which is made of a tubular pipe inner lining layer 11, pipe structure layer 12 and pipe outer protective layer 13 by winding to form an integrated structure (pipe wall), and the pipe structure layer 12 is located in the pipe Between the liner 11 and the pipe outer protective layer 13; the materials of the pipe inner liner 11 and the pipe outer protective layer 13 are thermoplastics, and the material of the pipe structure layer 12 is continuous long fiber.

[0026] The manufacturing process of the above-mentioned continuous long fiber winding reinforced thermoplastic pipe, it comprises the following steps:

[0027] 1) Set no less than 3 extrusion ports at the exit of the extruder (or injection molding machine) 8 (the extruder 8 has the function of heating and melting thermoplastics and extruding them, and there are two extrusion ports to extrude strip-shaped thermoplastics), the extrusion port includes an inn...

Embodiment 2

[0034] It is basically the same as that of Example 1, except that the continuous long fibers are basalt fibers matched with thermoplastics after surface treatment.

[0035] The thermoplastic is polyvinyl chloride (PVC).

Embodiment 3

[0037] It is basically the same as that of Example 1, except that the continuous long fibers are carbon fibers matched with thermoplastics after surface treatment.

[0038] The said thermoplastic is polypropylene (PP).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com