Prediction method for zinc powder effectiveness coefficient in wet zinc smelting and copper removal process

A prediction method, a technology for hydrometallurgical zinc smelting, applied in the direction of improving process efficiency, etc., can solve problems such as inability to accurately correct the control amount of zinc powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

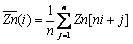

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: The copper removal process of the hydrometallurgy zinc smelting process in a certain lead-zinc factory is taken as an example to illustrate the superiority of the present invention. The first step is to use the actual production data to determine the effectiveness coefficient of the offline zinc powder; the second step is to predict the effectiveness coefficient of the zinc powder online based on the effectiveness coefficient of the offline zinc powder, combined with the adaptive window length adjustment algorithm and the gray time series prediction method, Offline measurement and online prediction comparison results, online prediction error such as image 3 (1 is the measured value of the effectiveness coefficient of offline zinc powder, and 2 is the predicted value of the effectiveness coefficient of online zinc powder), Figure 4 As shown, the error analysis of the online prediction value is shown in Table 1. From Attached Table 1, it can be seen that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com