Low grade zinc concentrate associated lead and silver recovery process

A zinc concentrate, low-grade technology, applied in the direction of improving process efficiency, etc., can solve the problems of low recovery rate and few types of recycled metals, etc., achieve the effect of thorough decomposition, improve the level of comprehensive utilization, and extend the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

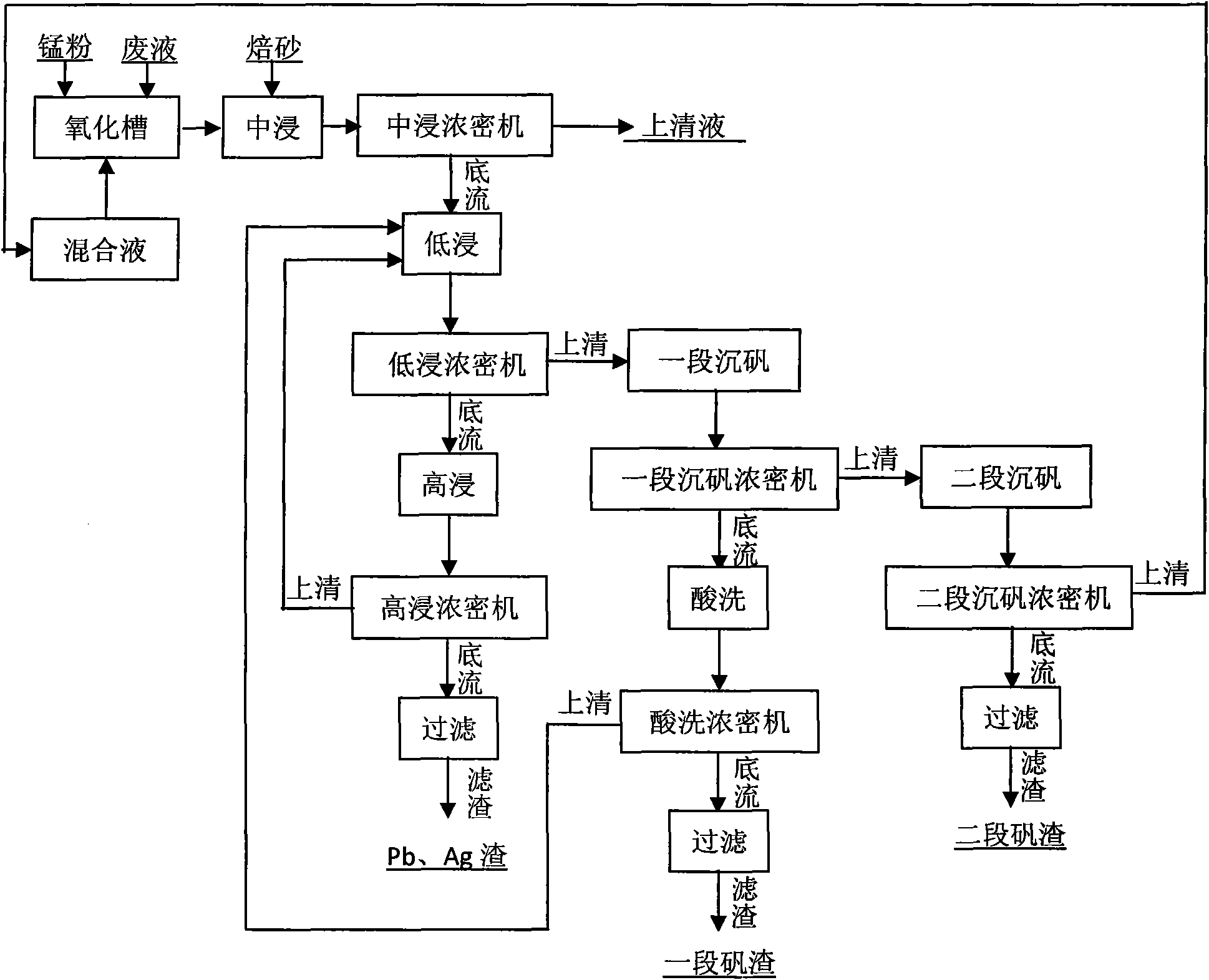

[0042] The above-mentioned low-grade zinc concentrate associated lead, silver recovery process, its process steps are further:

[0043] 1) Neutral leaching: neutral leaching is the process of leaching zinc from zinc calcine through the mixed reaction of sulfuric acid and zinc calcine.

[0044] Reaction temperature: 70°C-80°C; Reaction time: 2.5h-3h; Liquid-solid ratio: 7-9:1; Final acidity: pH=5.2-5.4, medium-intensity stirring;

[0045] 2) Low-acid leaching: Low-acid leaching is through the full reaction of high-acid supernatant and neutral leaching low flow. First, the zinc in the neutral leaching low flow should be leached as low as possible. During this process, the generation of "jarsite" increases the amount of slag in low-acid leaching slag, which affects the grade of lead and silver in high-temperature and high-acid leaching slag;

[0046] Reaction temperature: 50°C-65°C; Reaction time: 1.5h-2.0h; Liquid-solid ratio: 5-7:1; Final acidity: 15g / L-19g / L; Medium-intensity...

Embodiment 2

[0056] Low acid leaching experiment

[0057] The results of the analysis of the supernatant of the high leaching are shown in Table 1

[0058] Table 1 Analytical data of high acid leaching supernatant (g / L)

[0059] Numbering

[0060] Experimental conditions: liquid-solid ratio: 5:1, reaction temperature 55-60°C, final acidity 15-19g / L, reaction time 1.5h, the experimental results are shown in Table 2:

[0061] Table 2 Data analysis of bottom leaching test results (g / L)

[0062] Numbering

[0063] The experimental conclusions show that the generation of jarosite is effectively avoided in the low-acid leaching process, and there is almost no jarosite slag in the low-leaching underflow.

[0064] High acid leaching test

[0065] Experimental conditions: liquid-solid ratio 8:1, reaction temperature 90-95°C, final acidity 85-100g / L, reaction time 3h, the experimental results are shown in Table 3:

[0066] Table 3 Analysis data of high acid leaching experim...

Embodiment 3

[0075] Implementation of two-stage sinking alum-enriching silver leaching process

[0076] neutral leaching

[0077] Process principle

[0078] Add waste electrolyte, mixed solution, alum supernatant, anode mud slurry and manganese ore powder into the oxidation tank to control the acidity in the tank to 40-60g / L to ensure that the filtrate contains Fe 2+ <0.1g / L, continuously enter the first tank of the neutral leaching tank through the overflow port on the tank.

[0079] Four neutral leaching tanks are operated continuously in series. The calcined sand material is added to the first neutral leaching tank through the screw conveyor, and at the same time, the oxidizing solution flows into the first intermediate leaching tank through the chute, and the waste electrolyte is added to the oxidation tank and the first intermediate leaching tank according to the ratio of acid and zinc. The amount of addition is measured with PH test paper, and the pH of the outlet of the fourth ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com