Surface modified graphene polymer-based piezoresistive composite material and preparation method thereof

A composite material and surface modification technology, applied in the field of piezoresistive composite materials and their preparation, to achieve the effects of excellent piezoresistive repeatability, reducing surface energy and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

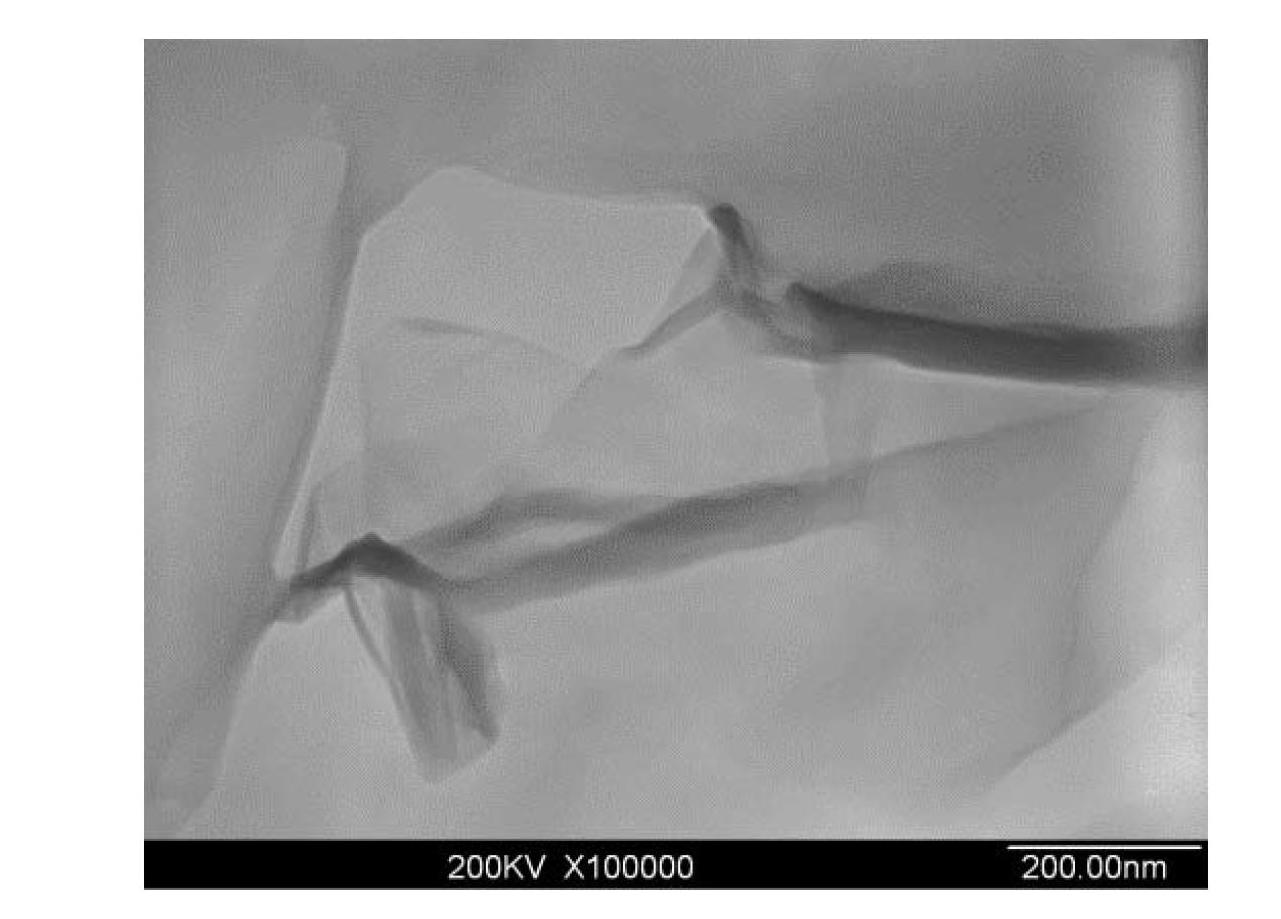

[0032] 1) All test materials were dried in a vacuum drying oven at 80°C for 24 hours before the experiment to remove the moisture in them. Graphite oxide prepared by the Hummers method was dispersed in water at a concentration of 2.5 mg / mL, and the pH value was adjusted to 8 with ammonia water, and a uniformly dispersed brownish-brown graphene oxide dispersion could be obtained by ultrasonic treatment. In the next step, 20 mL of ethanol solution with a concentration of 5.0 mg / mL octadecylamine prepared in advance was added to 40 mL of graphene oxide dispersion, and heated at reflux at 90 °C for 20 h. Then 0.1 mL of hydrazine hydrate (the ratio of hydrazine hydrate to graphite oxide is 1 mL:1 g) was added to the mixture, and the reaction was continued at 90 °C for 4 h. After the reaction, the product was repeatedly washed with hot ethanol at 60 °C through the mobile phase filter. After cleaning, the obtained product was put into a vacuum drying oven at 70°C and stored for 24 h...

Embodiment 2

[0038] 1) The surface alkylation modified graphene process is the same as Example 1;

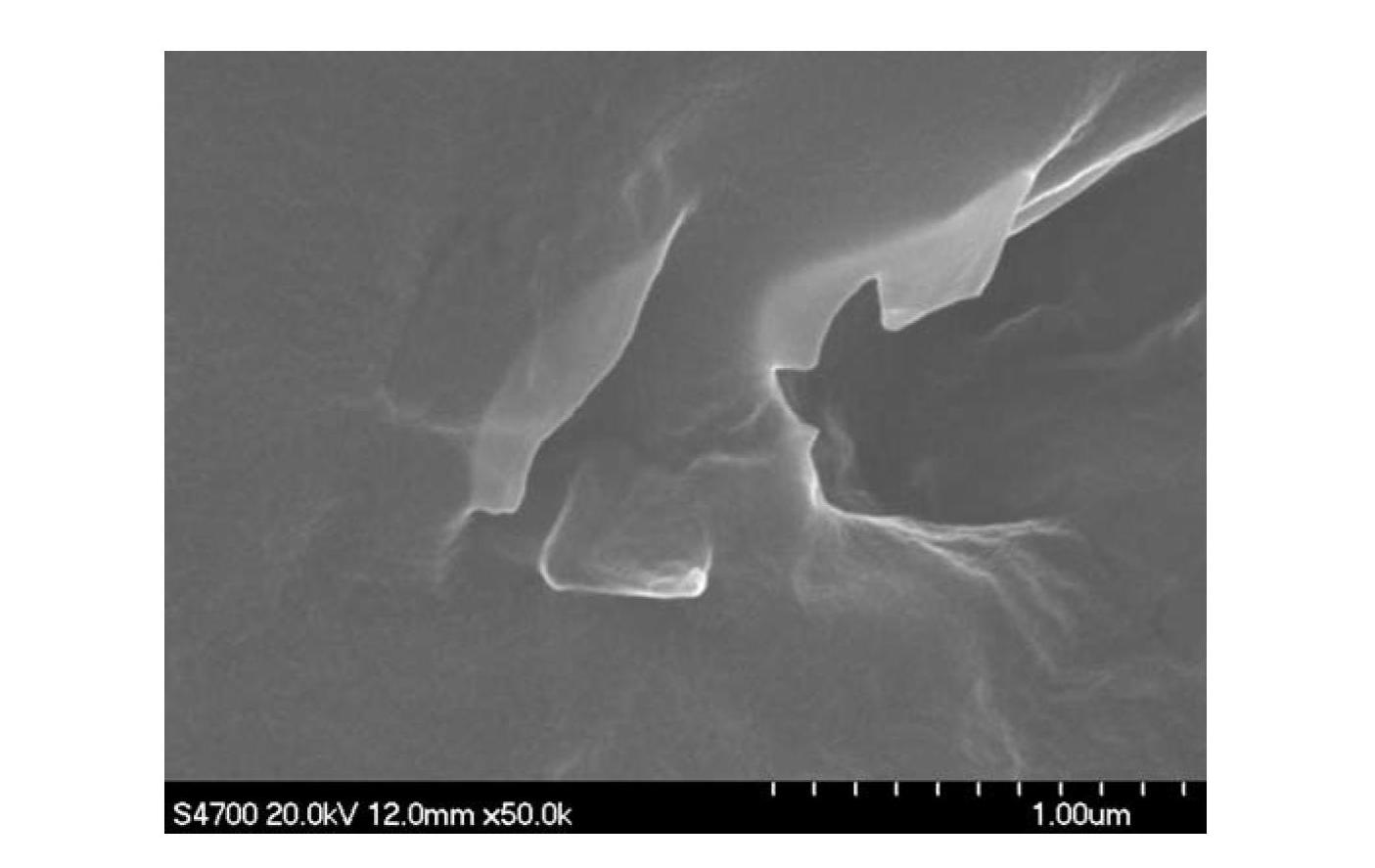

[0039] 2) Weigh 50 mg of the surface alkylation-modified graphene obtained in the first step, then add it into 50 mL of xylene solvent and perform ultrasonic treatment for 2 hours, and a stable graphene concentration of 1 mg / mL can be obtained. Dispersions. In the next step, 2 g of silicone rubber was dissolved in 10 mL of xylene solvent to prepare a silicone rubber dispersion with a concentration of 0.2 g / mL, mixed with the surface alkylation-modified graphene dispersion and stirred at room temperature for 30 minutes, and then the mixture was transferred to The solvent was evaporated by magnetic stirring at 80°C on a hot stage, and the obtained product was further dried in a vacuum oven at 80°C.

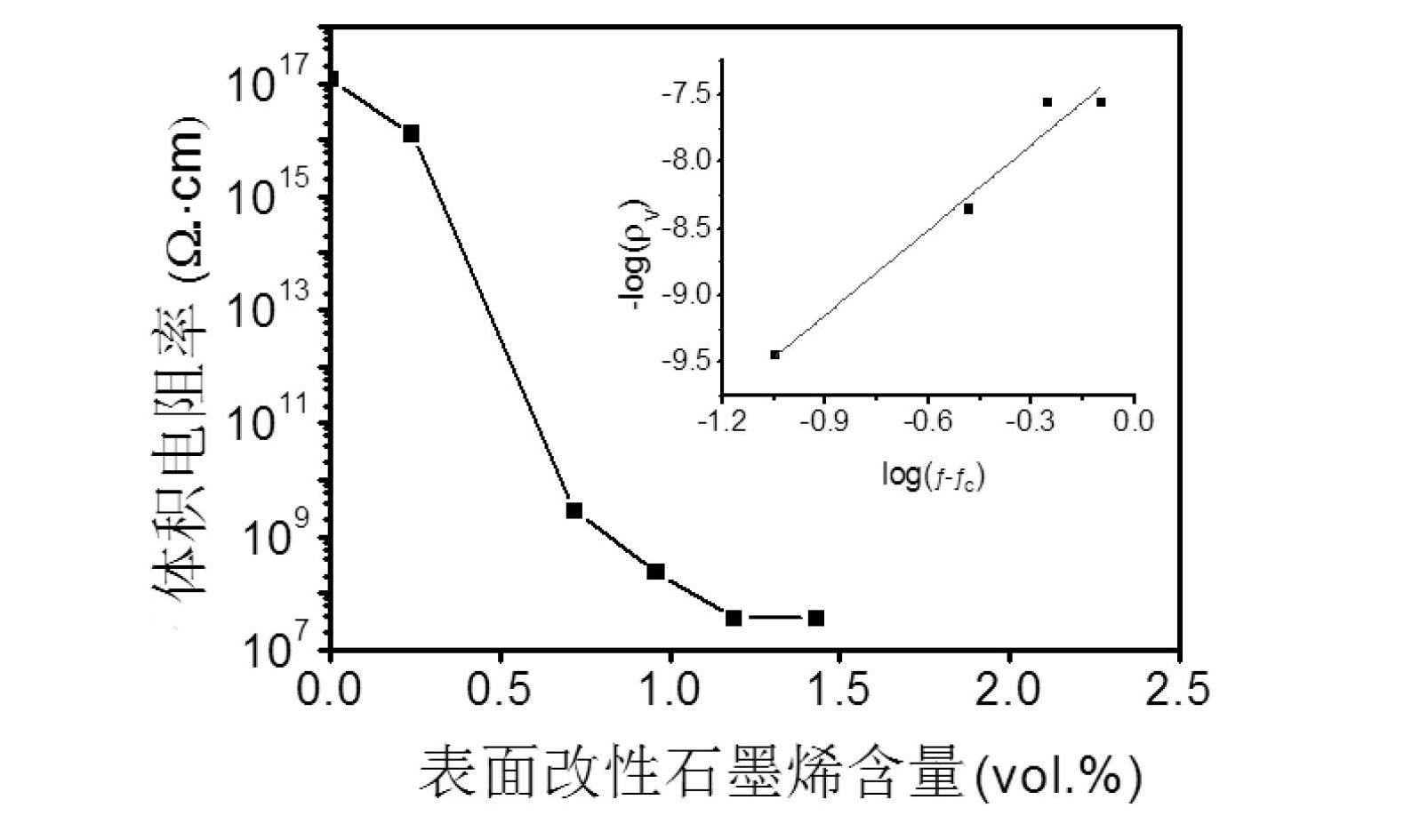

[0040] 3) In step 2) to obtain a composite material with a graphene volume fraction of 1.19%, add a curing agent tetraethyl orthosilicate and stir evenly, then put it into a mold and cure it at r...

Embodiment 3

[0045] 1) The surface alkylation modified graphene process is the same as Example 1;

[0046] 2) Weigh 60 mg of the surface alkylation-modified graphene obtained in the first step, then add it into 60 mL of xylene solvent and perform ultrasonic treatment for 2 hours, and a stable graphene concentration of 1 mg / mL can be obtained. Dispersions. In the next step, 2 g of silicone rubber was dissolved in 10 mL of xylene solvent to prepare a silicone rubber dispersion with a concentration of 0.2 g / mL, mixed with the surface alkylation-modified graphene dispersion and stirred at room temperature for 30 minutes, and then the mixture was transferred to The solvent was evaporated by magnetic stirring at 80°C on a hot stage, and the obtained product was further dried in a vacuum oven at 80°C.

[0047] 3) Add 7 parts of tetraethyl orthosilicate to the composite material with a graphene volume fraction of 1.43% in step 2) and stir evenly, then put it into a mold and cure it at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com