Application of organic silicon modifier in modified thermosetting phenolic resin

A technology of silicon modifier and phenolic resin, which is applied in the direction of silicon organic compounds, etc., can solve the problems of uncertain resin structure and molecular weight distribution, unstable product quality, etc., and achieve stable physical and chemical properties, stable product quality, and not easy to absorb water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

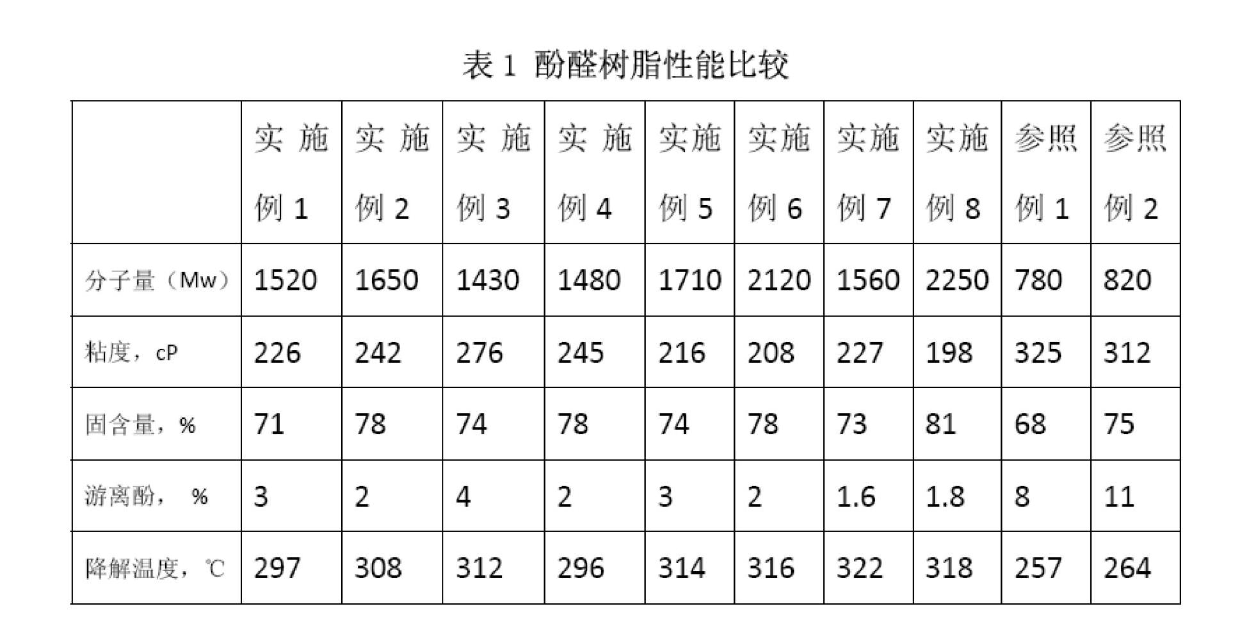

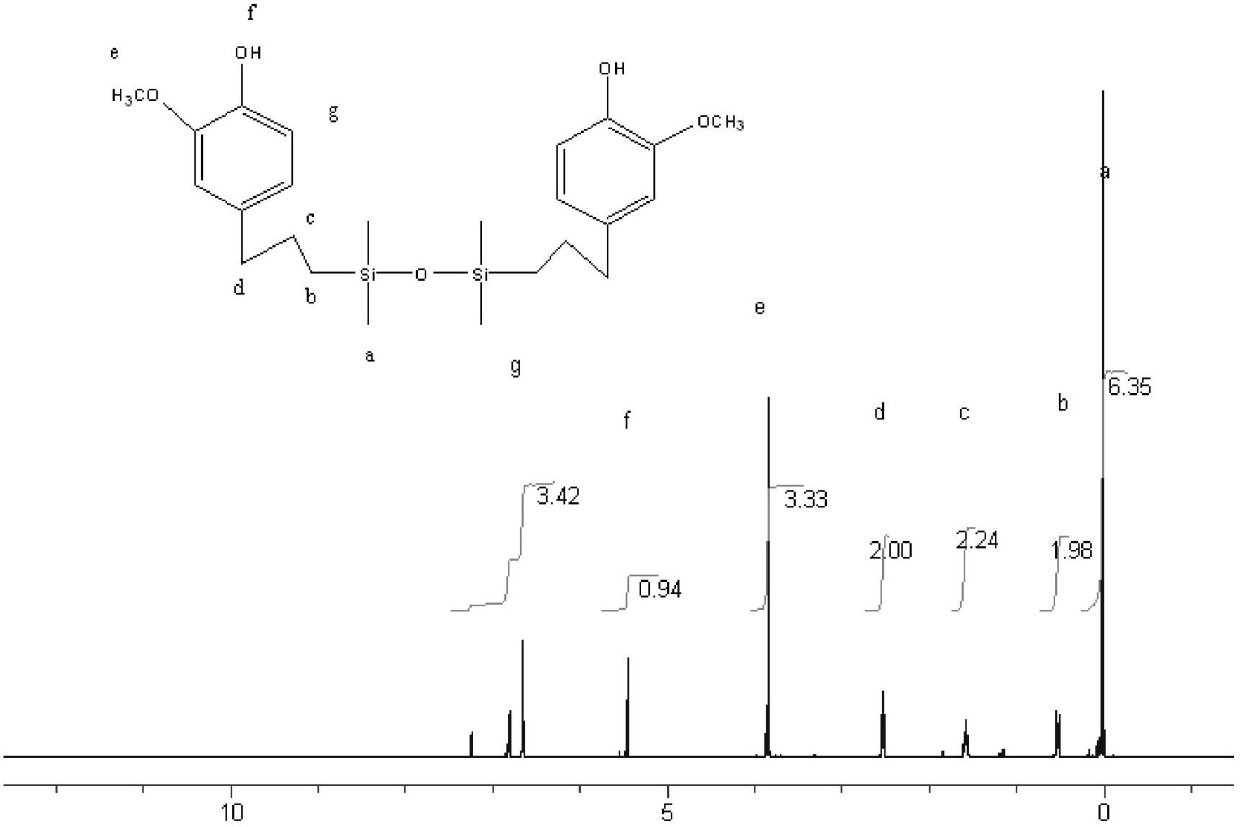

[0039] Add 14.76g of eugenol (164kg, 1000mol) and isopropanol solution of chloroplatinic acid (platinum mass percentage 0.8%) into the synthesis reaction kettle, stir and raise the temperature to about 60°C, and 1,1,3,3-tetramethyl Disiloxane (67kg, 500mol) was added dropwise into the reactor in batches to keep the temperature not higher than 80°C, and the reaction continued for 2 to 3 hours after the end of the heating phenomenon to obtain the organosilicon modifier. Productive rate 93%, the structural formula and nuclear magnetic spectrum of this organosilicon modifier are as figure 1 shown.

[0040]Add 80kg of phenol, 10kg of organic silicon modifier, and 2.7kg of sodium hydroxide into the synthesis reaction kettle, heat up and stir, the temperature rises to about 60°C, add dropwise 100kg of formaldehyde solution with a mass fraction of 37%, and heat up to 80~85°C for reaction after dropping After 130 minutes, neutralize with 5% hydrochloric acid to pH = 7, vacuum dehydrat...

Embodiment 2

[0044] Add 8.77g of eugenol (82kg, 500mol) and isopropanol solution of chloroplatinic acid (platinum mass percentage 0.8%) into the synthesis reaction kettle, stir and heat up to about 60°C, and 1,1,3,3-tetramethyl Disiloxane (33.5kg, 250mol) was added dropwise into the reactor in batches to keep the temperature not higher than 80°C, and the reaction continued for 2 to 3 hours after the end of the heating phenomenon, and then the organosilicon modifier was made , yield 94%.

[0045] Put 100kg of phenol, 10kg of organic silicon modifier, 3.3kg of sodium hydroxide into the synthesis reaction kettle, heat up and stir, the temperature rises to about 60°C, add dropwise 285kg (37wt%) of formaldehyde solution, and raise the temperature to 80~85°C after dropping React for 130 minutes, neutralize with 5% hydrochloric acid to pH = 7, vacuumize and dehydrate under reduced pressure under heating until the temperature is about 90°C, stop heating, add 40kg of ethanol and stir evenly to obta...

Embodiment 3

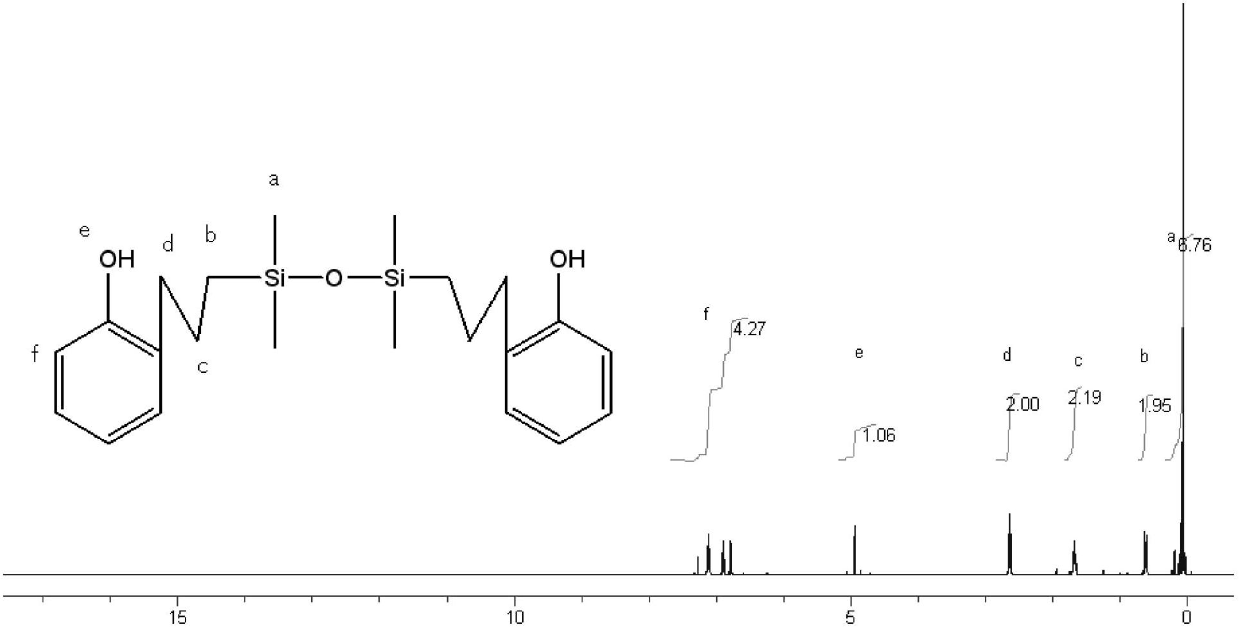

[0049] Add 14.76 g of 2-allylphenol (133 kg, 1000 mol) and chloroplatinic acid isopropanol solution (platinum mass percentage 0.8%) into the synthesis reactor, stir and heat up to about 60 ° C, and mix 1, 1, 3, 3-Tetramethyldisiloxane (67kg, 500mol) was added dropwise into the reactor in batches to keep the temperature not higher than 80°C, and the reaction continued for 2 to 3 hours after the end of the heating phenomenon to produce 2- Allylphenol type organosilicon modifier, productive rate 91%, the structural formula and nuclear magnetic spectrum of this allylphenol type organosilicon modifier are as figure 2 shown.

[0050] Add 80kg of phenol, 10kg of organic silicon modifier and 2.7kg of sodium hydroxide into the synthesis reaction kettle, heat up and stir, the temperature rises to about 60°C, add dropwise 100kg of formaldehyde solution with a mass percentage content of 37%, keep it for a period of time after dropping, and then Then raise the temperature to 90~95°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com