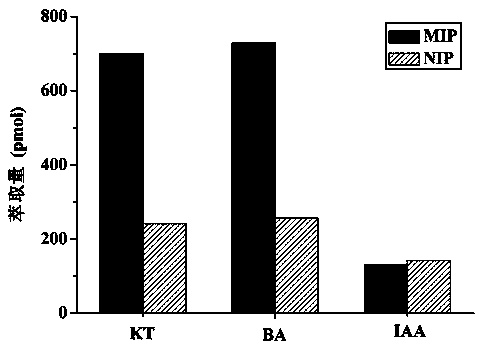

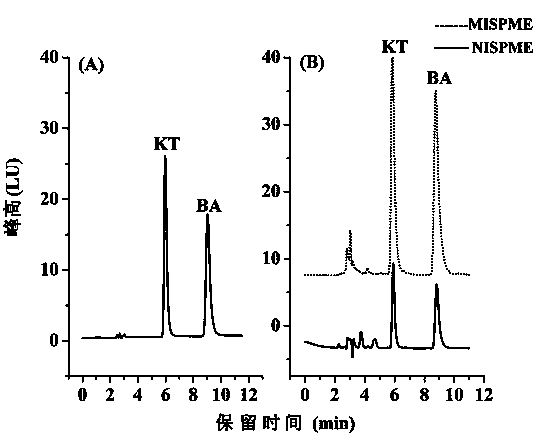

6-kinetin molecularly imprinted polymer and application thereof

A technology of furfurylaminoadenine and molecular imprinting, which is applied in the field of analytical chemistry, can solve the problems of limited development, and achieve the effects of wide application range, increased sensitivity, and increased enrichment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of MIP: A. Dissolve 17 mg template molecule KT and 150 μL methacrylic acid (functional monomer) in 3.6 mL absolute ethanol (porogen), shake well, place at room temperature for 12 h, then add 450 μL of trimethylolpropane trimethacrylate (cross-linking agent) and 34 mg of azobisisobutyronitrile (initiator) were used to obtain a pre-polymerization solution. After ultrasonication for 5 min, nitrogen gas was passed into the polymerization solution for 10 min. B. Add the above-mentioned pre-polymerization solution into a 2.0 mL derivatization vial, and place it in an oven at 60 °C for more than 8 hours. After the polymerization reaction is completed, KT-MIP will be generated.

Embodiment 2

[0048] Preparation of MISPE column: Prepare KT-MIP according to Example 1. In order to remove the template molecule KT, solid MIP is ground into powder, wrapped with filter paper, placed in a Soxhlet extractor, and 150 mL of absolute ethanol-acetic acid (90: 10, v / v) eluate, reflux at 85°C to elute the template molecule until KT is no longer detected by HPLC. Select several 5 mL syringe barrels, fill the polytetrafluoroethylene sieve plate in the bottom of the syringe barrel, weigh 250 mg of the treated KT-MIP and NIP powders into the above syringe barrels, beat the filler evenly, and then polymerize Another piece of polytetrafluoroethylene sieve plate was plugged on top of the object and compacted. Finally, MISPE column and NISPE column are produced.

Embodiment 3

[0050] Preparation of MISPME fiber coating: Take a 20 cm long quartz fiber, soak one end in acetone for 5 min, peel off the outer polyimide coating, and use secondary water, 1.0 mol / L NaOH, secondary water, Soak in 1 mol / L HCl, wash, dry, put the quartz fiber into 10% (v / v) γ-MAPS acetone solution for silanization treatment for 2 h, take it out, rinse it with methanol, and dry it with nitrogen. Prepare the pre-polymerization solution according to step A) of Example 1 and transfer it to a 2.0 mL derivatization vial, insert the silanized fiber, and react in an oven at 60 °C for 8 h. According to the same procedure and polymerization method, the same fiber is repeatedly coated with copolymerization to obtain a certain thickness of MISPME coating. After the coating was prepared, the template molecules were eluted with absolute ethanol-acetic acid (90:10, v / v) to remove template molecules until no template molecules were detected in the eluent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com