Reversed-order SBR (Sequencing Batch Reactor) water processing device and method for enhanced nitrogen removal

A water treatment device and water treatment technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as heavy maintenance workload, complicated operation management, and sludge loss , to achieve the effect of reducing operating costs, reducing infrastructure investment, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

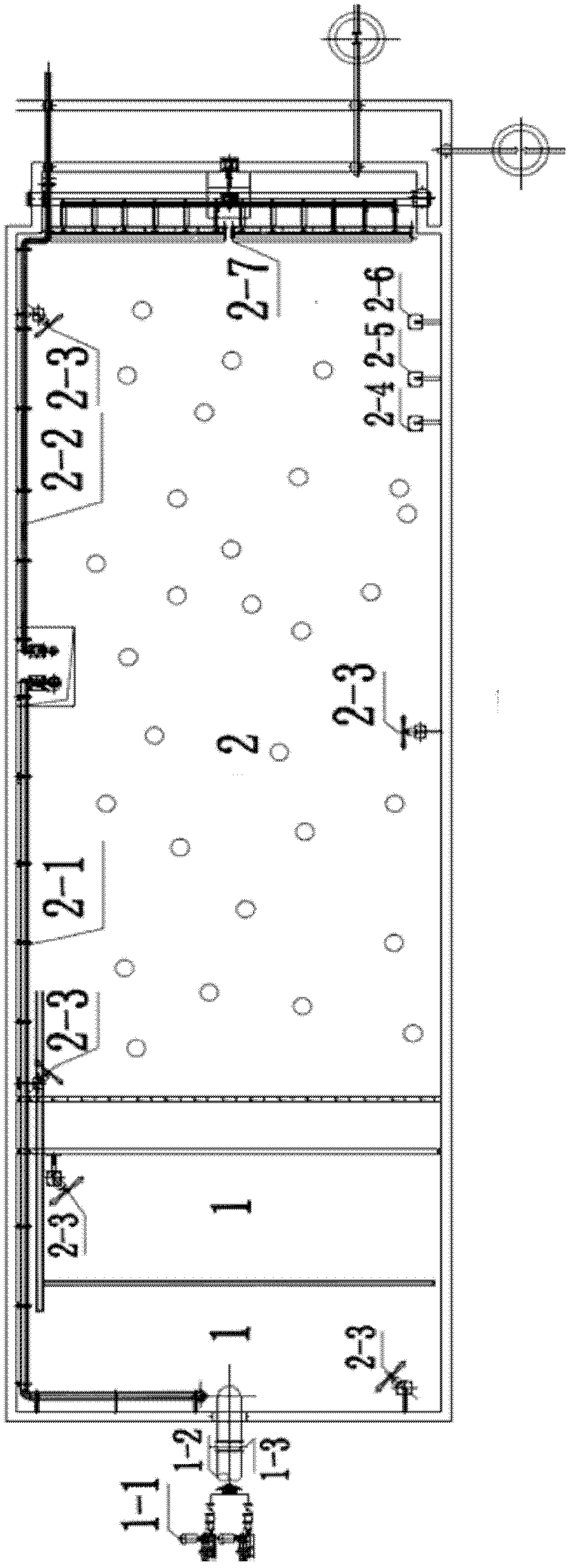

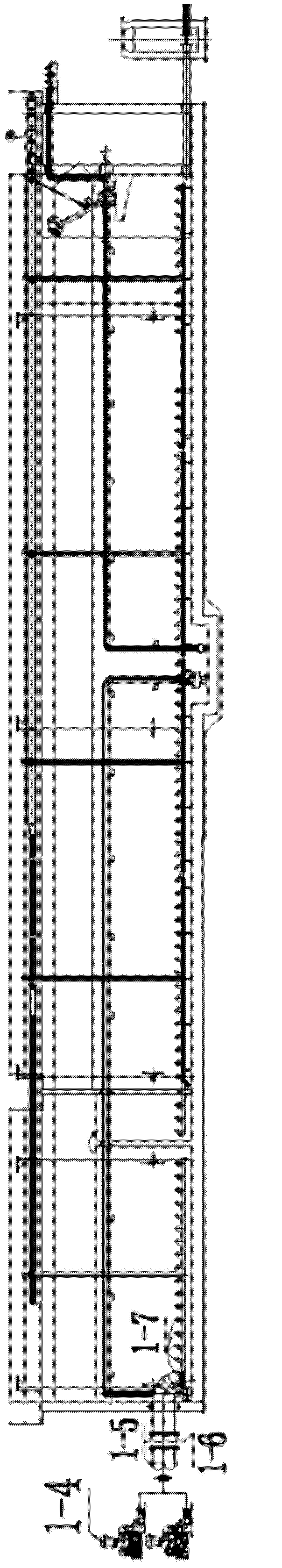

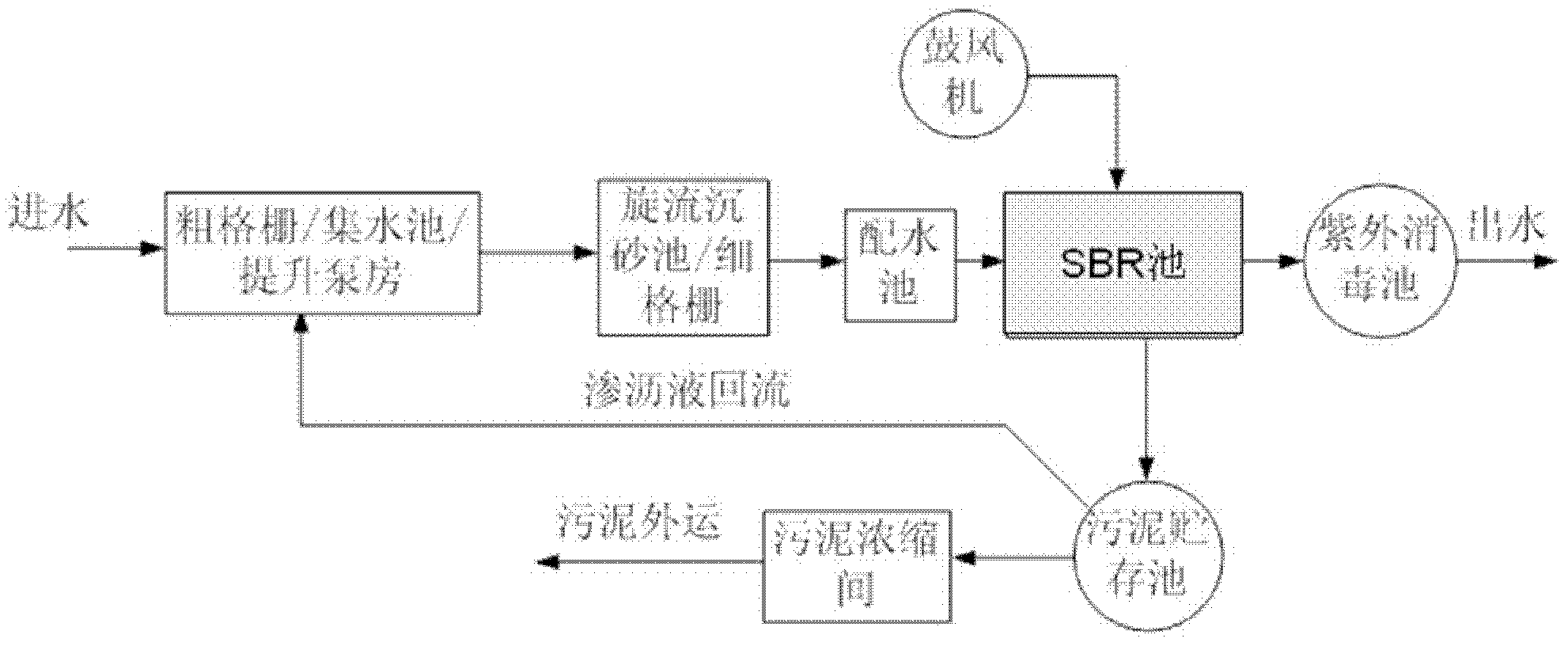

[0052] figure 1 and figure 2 Respectively show a structural schematic diagram and a top view of a reverse sequence SBR water treatment device for enhanced denitrification in this embodiment, the reverse sequence SBR water treatment device in the present invention mainly includes anaerobic denitrification denitrification, anaerobic phosphorus release, The reverse sequence SBR pool for aerobic nitrification and aerobic phosphorus uptake reaction, the front end of the reverse sequence SBR pool is connected to the sewage water inlet device, and the rear end is connected to the water outlet device; the reverse sequence SBR tank is equipped with aeration device, submersible mixer 2-3, The pH sensor 2-4, the dissolved oxygen sensor 2-5 and the redox sensor 2-6, the pH sensor 2-4, the dissolved oxygen sensor 2-5 and the redox sensor 2-6 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com