Method for purifying ferric oxide red by wet method

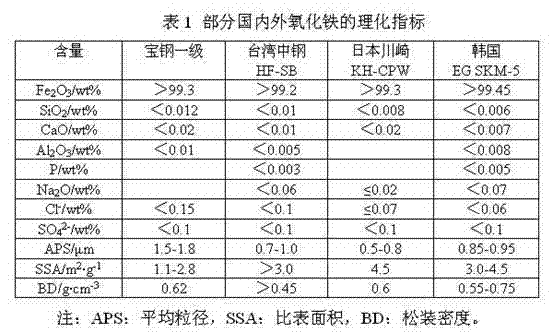

A technology of wet purification and iron oxide red, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of poor consistency, large fluctuations, chemical index CL not reaching ultra-high purity iron oxide powder, etc., and achieve The effect of improving the chemical performance index and physical performance index and improving the consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step a: Transport the cold-rolled pickled iron red in the storage tank to the dissolution kettle through a metering belt scale, and dissolve it according to the ratio of cold-rolled pickled iron red and deionized water at a ratio of 1:5, and add ammonia content of 20% Ammonia water is used as an additive, and then the slurry is kept at a temperature of 30° C., and the rotation speed is 50 rpm for stirring, stirring for 20 minutes;

[0036] Step b: Grind the slurry with a ball mill to keep the diameter of the solid particles at 0.5-1.0 microns. After grinding, send the slurry to the CF-1500I centrifugal dehydrator (such as figure 1 Shown) to separate the impurities, separate the solid from the liquid, and control the water content to be less than 30%;

[0037]Step c: The separated liquid is sent to the storage tank, and discharged after treatment. The separated solid is sent to the dissolving tank, and then step a is carried out, and then the slurry is sent to the CF-1...

Embodiment 2

[0041] Step a: The cold-rolled pickled iron red in the storage tank is transported to the dissolution kettle through a metering spiral belt, and dissolved according to the ratio of cold-rolled pickled iron red and deionized water at a ratio of 1:2, and the content of ammonia added is 10% Ammonium carbonate is used as an additive, and then the slurry is kept at a temperature of 50 ° C, and the rotation speed is stirred at 20 rpm for 80 minutes;

[0042] Step b: Grind the slurry with a ball mill to keep the solid particle diameter at 0.5-1.0 microns. After grinding, send the slurry to the CF-1500I centrifugal dehydrator through a hose pump to separate impurities, separate the solid and liquid, and control After filtering, the water content is less than 30%;

[0043] Step c: The separated liquid is sent to the storage tank, and discharged after treatment. The separated solid is sent to the dissolving tank, and then step a is carried out, and then the slurry is sent to the CF-150...

Embodiment 3

[0047] Step a: Transport the cold-rolled pickled iron red in the storage tank to the dissolution kettle through a metering belt scale, and dissolve it according to the ratio of cold-rolled pickled iron red and deionized water at a ratio of 1:9, and add ammonia content of 5% Ammonium bicarbonate is used as an additive, and then the slurry is kept at a temperature of 20 ° C, and the rotation speed is 100 rpm for stirring, stirring for 20 minutes;

[0048] Step b: Grind the slurry with a sand mill to keep the solid particle diameter at 0.5-1.0 microns. After grinding, send the slurry to the CF-1500I centrifugal dehydrator through a hose pump to separate impurities and separate the solid from the liquid. , the water content after control is less than 30%;

[0049] Step c: The separated liquid is sent to the storage tank, and discharged after treatment. The separated solid is sent to the dissolving tank, and then step a is carried out, and then the slurry is sent to the CF-1500I c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com