Nanometer magnetic iron oxide and preparation method and application thereof

A technology of iron oxides and arsenic compounds, which is applied in the field of environmental water treatment, can solve the problems of unfavorable industrialized large-scale wastewater treatment, low adsorption capacity, and difficult recovery, and achieves the effects of fast adsorption speed, large adsorption capacity, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 2mmol of FeCl 3 with 1mmol FeCl 2 Add 30ml of double distilled water, under stirring at 1000rpm, quickly add 7.5ml of 25% ammonia water, stir and react at room temperature for 20min, use a magnet to absorb the reaction product, separate from the liquid phase, wash 3 times with deionized water, and obtain the product The rate is 98.4%.

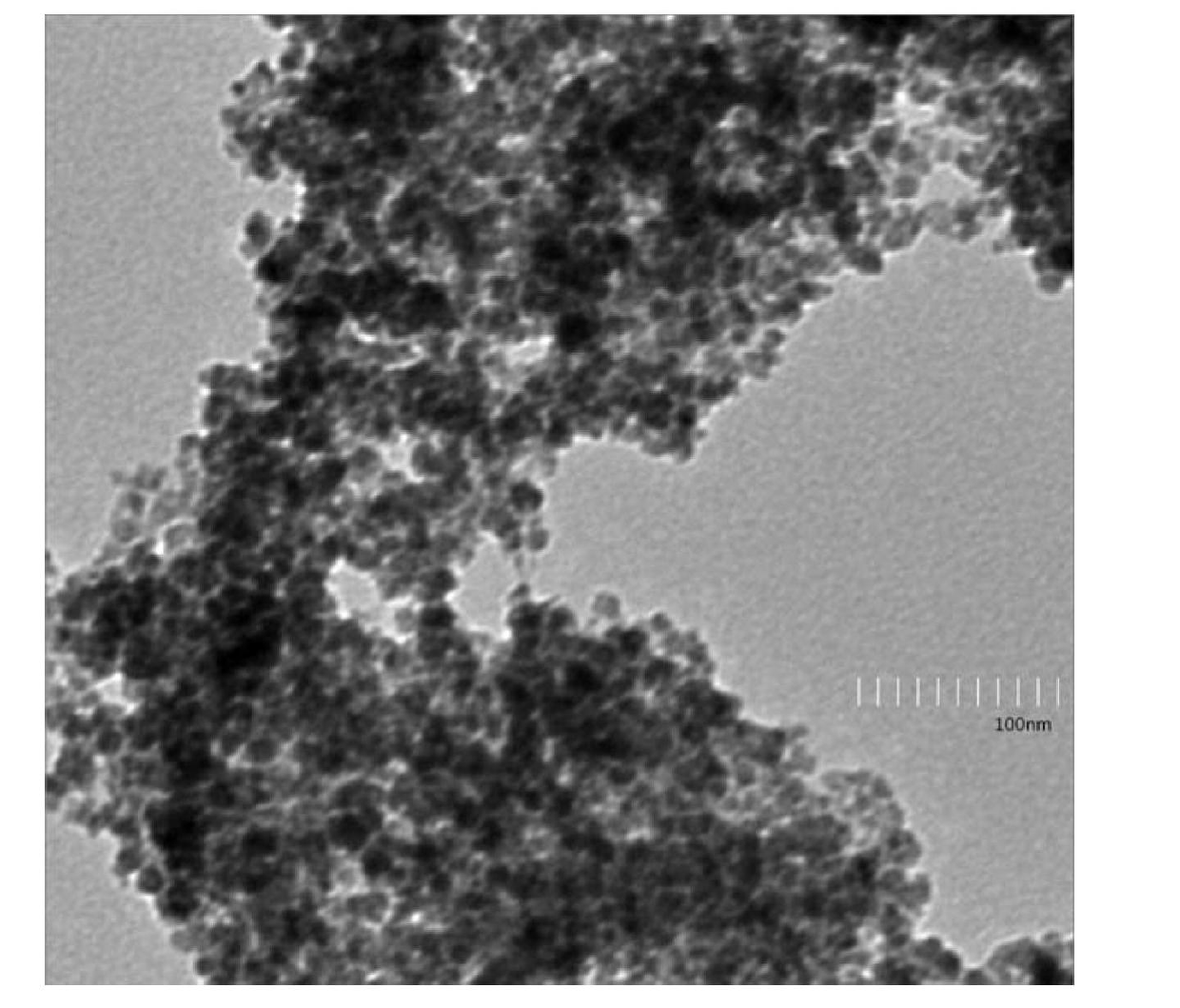

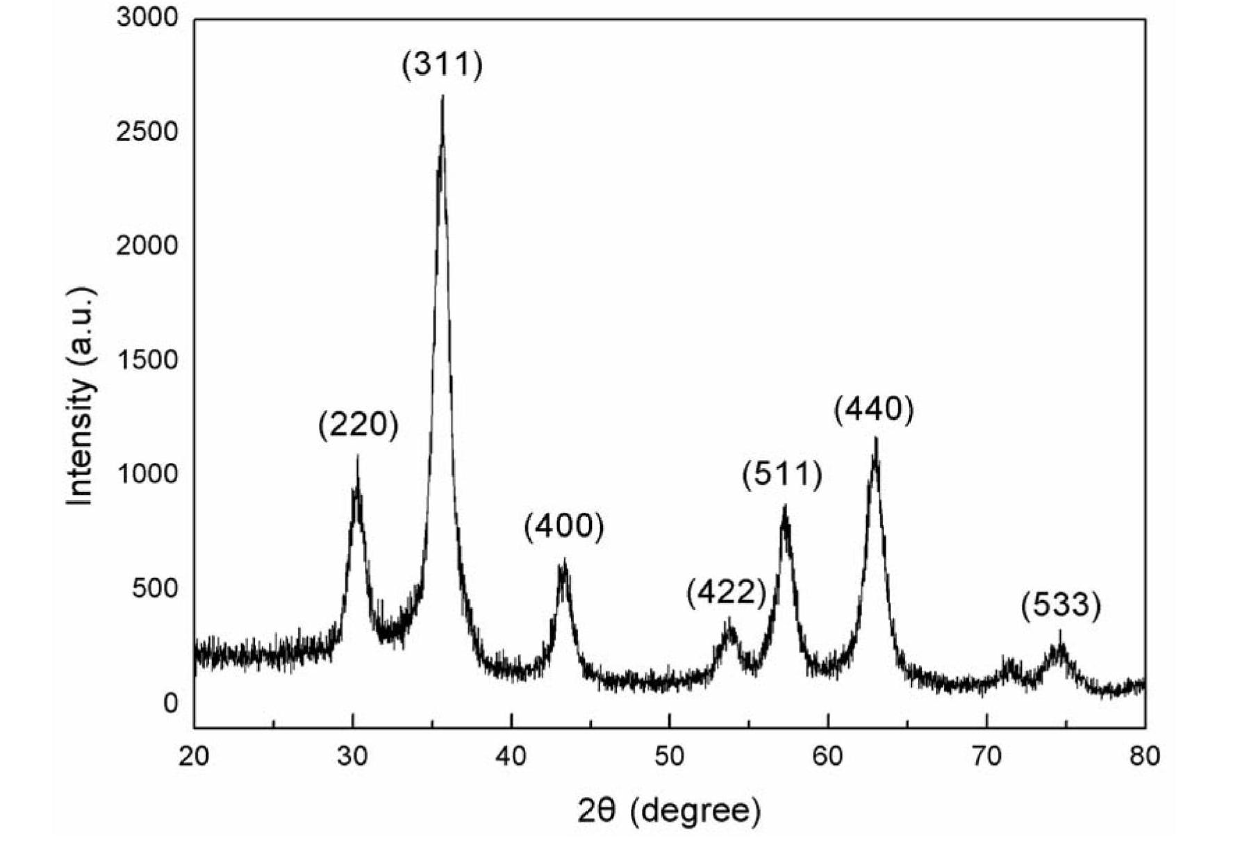

[0026] The particle size of the product is between 8-12nm, with figure 1 The transmission electron microscope (TEM) image of the prepared nano-scale magnetic iron oxide particles is attached. figure 2 The photo of the nano-scale magnetic iron oxide particles recovered by using a permanent magnet with a magnetic field strength of 0.5T is attached. image 3 X-ray diffraction pattern (XRD) of the prepared nano-scale magnetic iron oxide particle adsorbent, attached Figure 4 is the hysteresis curve of the prepared nano-scale magnetic iron oxide particle adsorbent. From the above, it can be seen that the product has a correct structure ...

Embodiment 2

[0028] 10mmol of FeCl 3 with 5mmol FeCl 2 Add 150ml of double distilled water, under stirring at 1000rpm, quickly add 38.5ml of 25% ammonia water, stir and react at room temperature for 20min, use a magnet to absorb the reaction product, separate from the liquid phase, wash 3 times with deionized water, and obtain the product The rate is 98.9%, and the particle diameter of this product is 8-12nm.

Embodiment 3

[0030] 20mmol of FeCl 3 with 10mmol FeCl 2 Add 300ml of double distilled water, under stirring at 1000rpm, quickly add 77ml of 25% ammonia water, stir at room temperature for 20min, use a magnet to absorb the reaction product, separate it from the liquid phase, and wash it with deionized water for 3 times. It is 96.8%, and the particle diameter of this product is 8-12nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com